Preparation method of water repellent for mineral fibers

A mineral fiber and water-repellent technology, applied in the field of water-repellent, can solve the problems of low popularity and popularization, poor stability, complex process, etc., and achieve the effect of simple process route, good stability, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

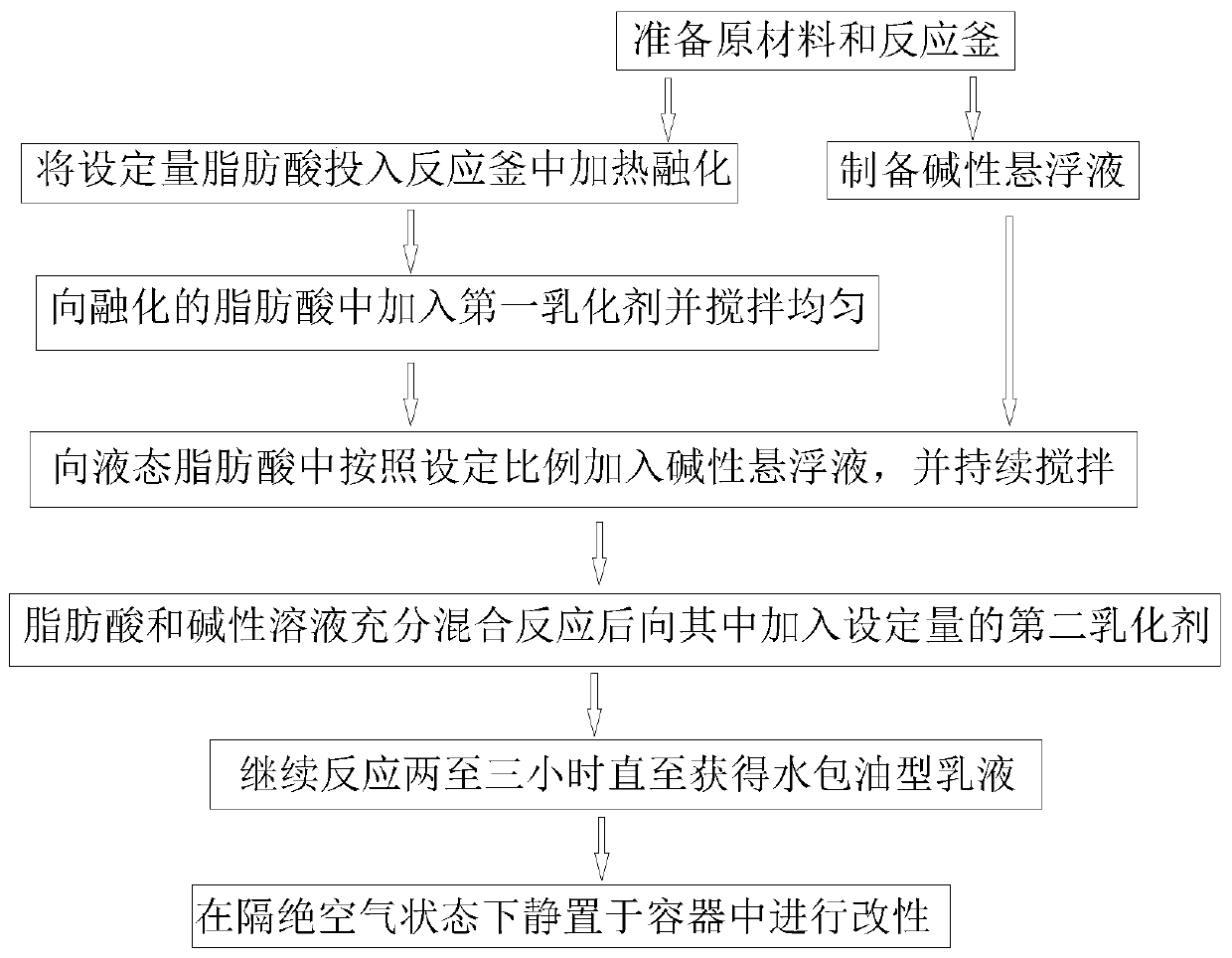

Method used

Image

Examples

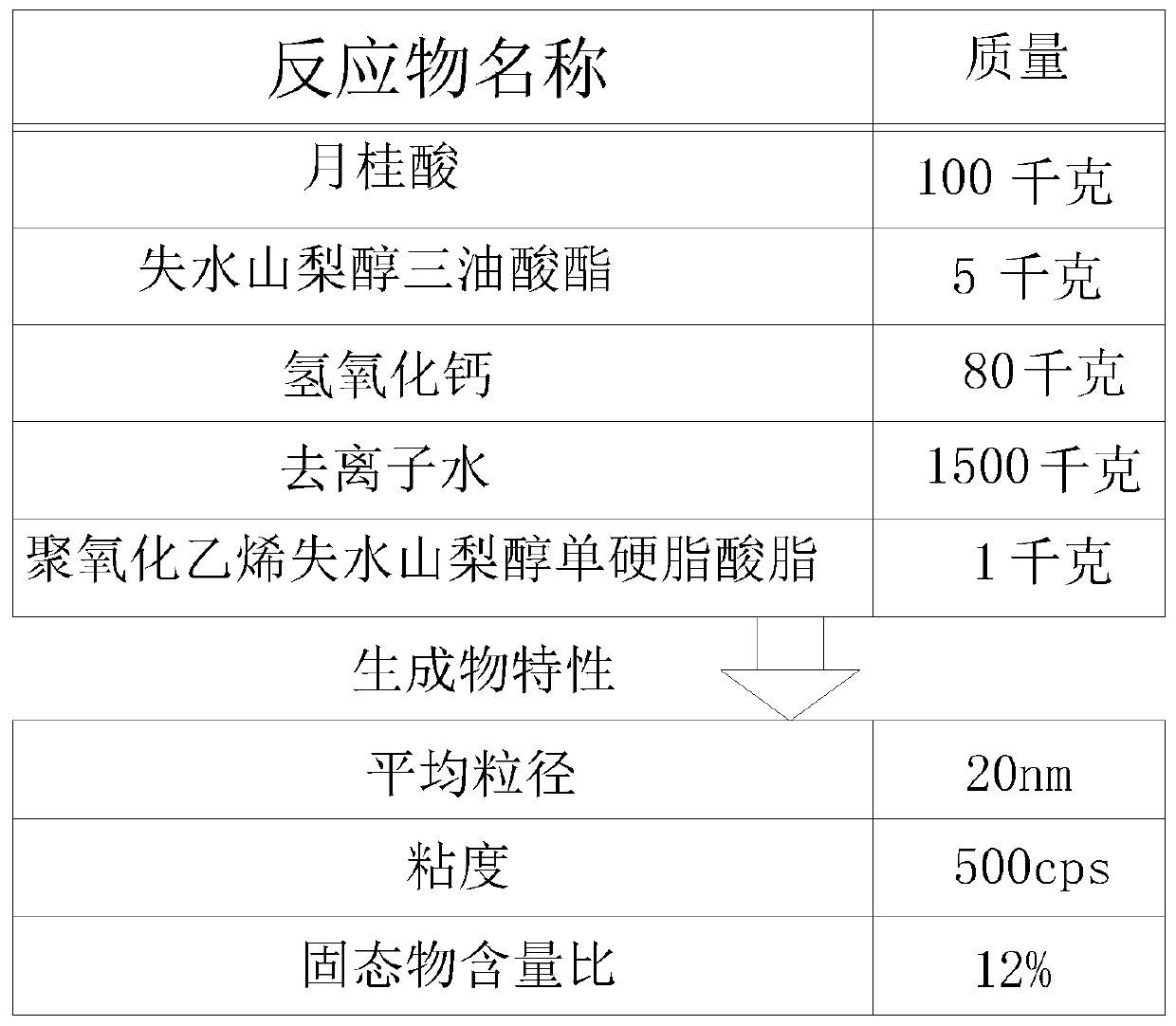

Embodiment 1

[0040] Embodiment 1: add 100 kilograms of lauric acid in the reactor, heat up to 90 degrees Celsius, after all melted, add 0.5 kilograms of sorbitan trioleate under stirring, at the same time 80 kilograms of calcium hydroxide are dropped into Add 1500 kg of deionized water to form a suspension, then inject the suspension into the reactor, and after two hours of heat preservation, add one kilogram of polyoxyethylene sorbitan monostearate, continue to stir rapidly for two hours, and then cool down To normal temperature, the average particle size of the obtained product is 20nm, the viscosity is 500cps, and the solid content ratio is 12%. The particle size test method: JL-1155 laser particle size distribution tester; viscosity: NDJ-1 type viscometer.

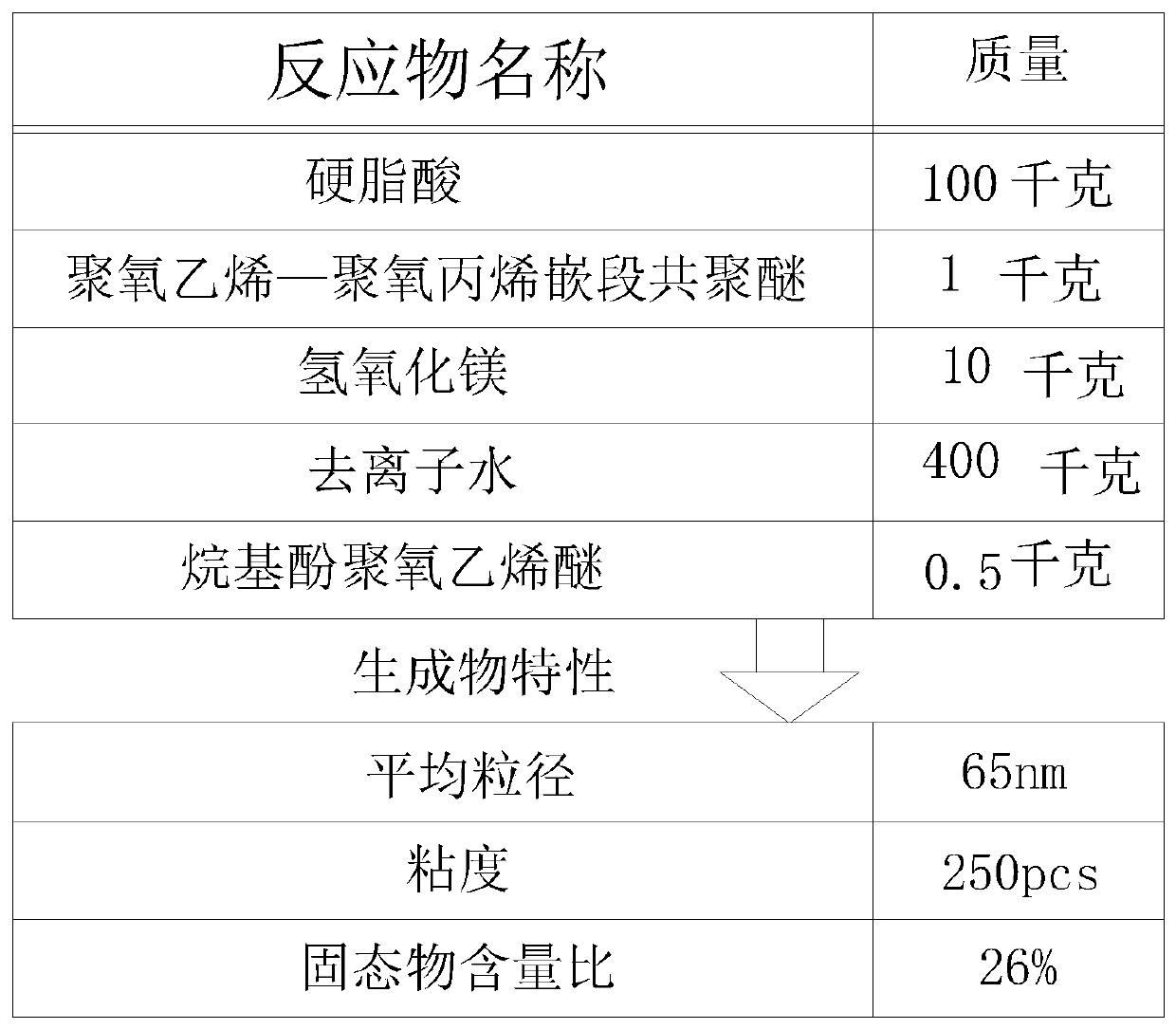

Embodiment 2

[0041] Embodiment 2: Add 100 kilograms of stearic acid in the reactor, heat up to 90 degrees Celsius, after all melted, add 1 kilogram of polyoxyethylene-polyoxypropylene block copolyether under stirring state, then oxidize 10 kilograms of hydrogen Magnesium was added to 400 kg of deionized water to form a suspension, and then injected into the reactor. After two hours of reaction, 0.5 kg of alkylphenol polyoxyethylene ether was further added, and the temperature was lowered to normal temperature after one hour of heat preservation reaction. Diameter 65nm, viscosity 250cps, the water-repellent agent that solid content ratio is 26%, test method is the same as embodiment 1.

Embodiment 3

[0042] Example 3: Add 100 kilograms of triacic acid to the reaction kettle, heat up to 90 degrees Celsius, after all melted, add 1 kilogram of fatty alcohol polyoxyethylene ether under stirring, add 20 kilograms of zinc hydroxide to 300 kilograms Deionized water forms a suspension, and then pours it into the reaction kettle for 3 hours to react, and further adds 1 kg of polyoxyethylene sorbitan monooleate, keeps it warm for 3 hours and then cools down to room temperature. The average particle size of the obtained product is 120nm, and the viscosity is 80cps , the proportion of solid content is 35%. Test method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com