Curable Resin Composition

A technology of curable resin and composition, applied in the direction of electrical components, printed circuits, printed circuit parts, etc., to achieve the effect of low roughness, low arithmetic mean roughness, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0127] [Preparation of Curable Resin Composition]

[0128] The curable resin composition of the present invention can be prepared by mixing the above-mentioned components appropriately, and using kneading equipment such as a three-roll mill, a ball mill, a bead mill, and a sand mill, or a high-speed rotary mixer, a high-speed mixer, and a planetary mixer as needed. It is prepared by kneading or mixing with stirring equipment such as a blender. In addition, it can also be prepared as a resin varnish by further adding the above-mentioned organic solvent.

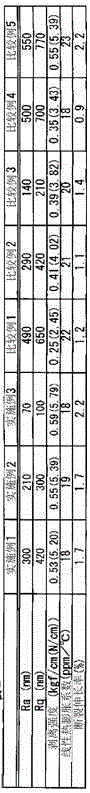

[0129] For the curable resin composition of the present invention, not only the arithmetic mean roughness of the surface of the insulating layer is low, but also the root mean square roughness is low, and a plated conductor layer with sufficient peel strength can be formed, so it can be used in multilayer printed wiring boards. It can be suitably used as a curable resin composition for an insulating layer of a multilayer prin...

Embodiment

[0166] The following examples illustrate the present invention in more detail, but the present invention is not limited by these examples. In the description below, "parts" means "parts by mass" unless otherwise specified, and "%" means "mass%" unless otherwise specified.

[0167]

[0168] First, various measurement methods and evaluation methods will be described.

[0169] [Preparation of samples for measurement of peel strength, arithmetic mean roughness (Ra value), root mean square roughness (Rq value)]

[0170] (1) Substrate treatment of laminated boards

[0171] Both sides of a glass cloth-based epoxy resin double-sided copper-clad laminate (the thickness of the copper foil is 18 μm, the thickness of the substrate is 0.3 mm, R5715ES manufactured by Panasonic Electric Works Co., Ltd.) are etched 1 μm with CZ8100 manufactured by Meck Co., Ltd. Roughening of copper surfaces.

[0172] (2) Lamination of adhesive film

[0173] The adhesive films produced in Examples and ...

Embodiment 2

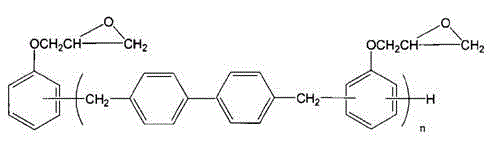

[0207] 5 parts of liquid naphthalene-type epoxy resin (epoxy equivalent 144, "HP4032SS" manufactured by DIC Corporation), 5 parts of crystalline bifunctional epoxy resin ("YX4000HK" manufactured by Mitsubishi Chemical Corporation, epoxy equivalent about 185) 5 parts 12 parts of biphenyl-type epoxy resin ("NC3000L" manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 269), heated and dissolved in 30 parts of mineral spirits while stirring. After cooling to room temperature (25°C), 5 parts of phenoxy resin A and a prepolymer of bisphenol A dicyanate ("BA230S75" manufactured by Ronza Japan Co., Ltd., cyanate equivalent weight about 232, 20 parts of MEK solution with 75% by mass of non-volatile content), 20 parts of novolak polyfunctional cyanate resin ("PT30S" manufactured by Ronza Japan Co., Ltd., about 133 cyanate equivalents, and 85% by mass of non-volatile content) MEK solution) 6 parts, curing accelerator (4-dimethylaminopyridine, MEK solution with a solid content of 2%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com