Cured organopolysiloxane resin film having gas barrier properties and method of producing the same

A polysiloxane resin, polysiloxane technology, applied in the directions of transportation, packaging, textile, coating, etc., can solve the problems of poor gas barrier properties and water vapor barrier properties, and uneven adhesion of silicon oxynitride films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0277] Other examples are as follows:

[0278] (3) Organopolysiloxanes including organopolysiloxanes lacking organofunctional groups and comprising at least two silicon-bonded alkenyl groups per molecule, organopolysiloxanes comprising at least one organofunctional group per molecule and at least two silicon-bonded hydrogen atoms per molecule Combinations of siloxanes (excluding, however, combinations of organopolysiloxanes comprising two silicon-bonded alkenyl groups with organopolysiloxanes comprising two silicon-bonded hydrogen atoms) and hydrosilylation catalysts things, and

[0279] (4) Includes organopolysiloxanes comprising at least one organofunctional group and at least two silicon-bonded alkenyl groups per molecule, at least one organofunctional group and at least two silicon-bonded hydrogens per molecule Atomic organopolysiloxanes (however, excluding combinations of organopolysiloxanes containing two silicon-bonded alkenyl groups with organopolysiloxanes containing...

specific example

[0291] Specific examples of organopolysiloxanes lacking organofunctional groups and containing at least two silicon-bonded alkenyl groups per molecule are as follows:

[0292] Dimethylpolysiloxane end-blocked at both ends with dimethylvinylsiloxy groups,

[0293] A dimethylsiloxane-methylvinylsiloxane copolymer end-blocked at both ends with trimethylsiloxy groups,

[0294] A dimethylsiloxane-methylvinylsiloxane copolymer end-blocked at both ends with dimethylvinylsiloxy groups,

[0295] Methyltris(dimethylvinylsiloxy)silane,

[0296] Methylphenylpolysiloxane end-blocked at both ends with dimethylvinylsiloxy groups,

[0297] a dimethylsiloxane-methylvinylsiloxane copolymer end-blocked at both ends with dimethylphenylsiloxy groups, and

[0298] A dimethylsiloxane-methylvinylsiloxane-methylphenylsiloxane copolymer end-blocked at both ends with dimethylvinylsiloxy groups.

[0299] In addition, specific examples of component (A) are also applicable here.

[0300] Specific exampl...

Embodiment 1

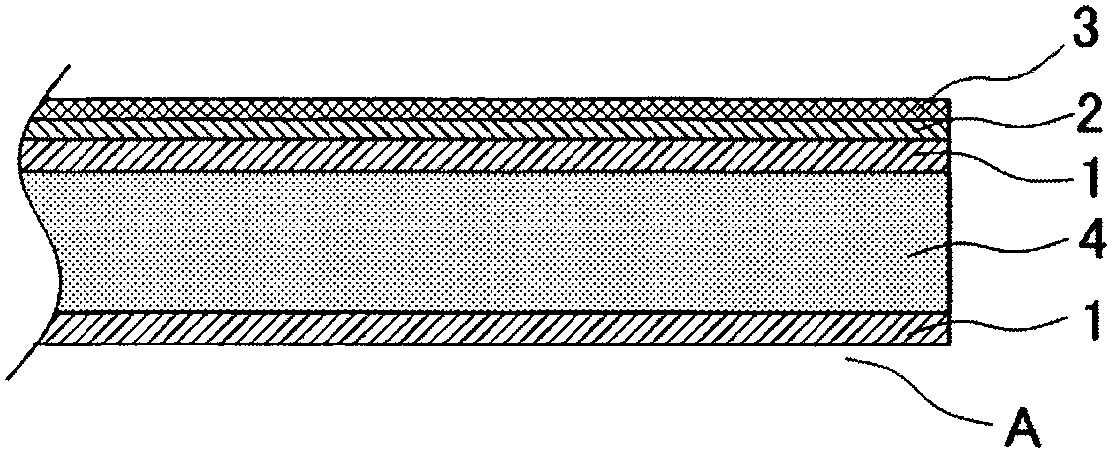

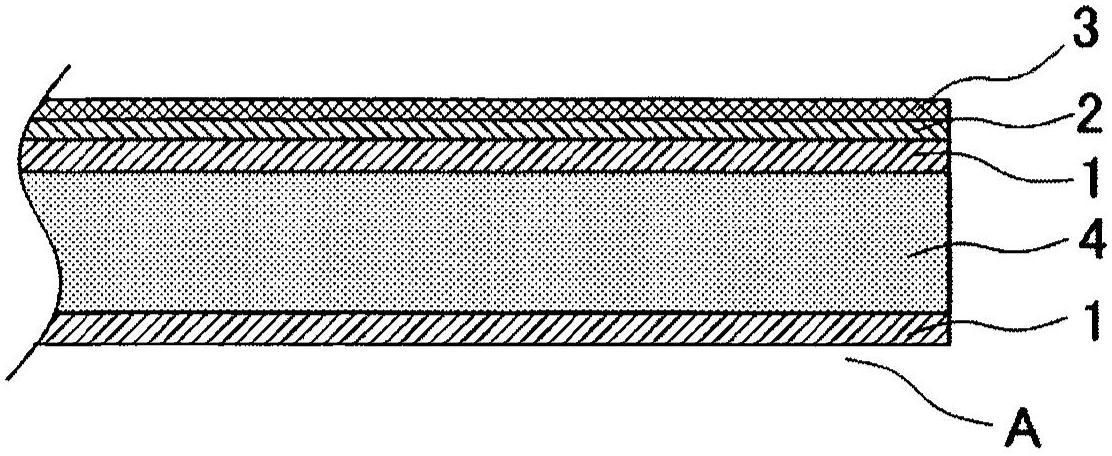

[0565] The coating solution obtained in Synthesis Example 2 was spin-coated at 2500 rpm for 30 minutes onto the cured methyl phenyl vinyl film having a width of 10 cm, a length of 10 cm and a thickness of 100 μm obtained in the aforementioned Reference Example. One side of glass fiber reinforced membrane (A) made of polysiloxane resin. The 3-methacryloxy groups of poly(phenyl-co-3-methacryloxypropyl)silsesquioxane were polymerized with each other by exposing the coated side to UV radiation for 15 minutes using 200W Hg-Xe lamp, exposure dose is 30mW / cm 2 , and thereafter held at 150° C. for 120 minutes to cure the poly(phenyl-co-3-methacryloxypropyl)silsesquioxane.

[0566] A silicon oxynitride layer having a thickness of 30 nm, that is, a silicon oxynitride film was formed on the cured poly(phenyl-co-3-methacryloxypropyl)silsesquioxane layer by ion plating.

[0567] Using silica rods as the film-forming material, using N 2 Argon was used as the reaction gas, argon was used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com