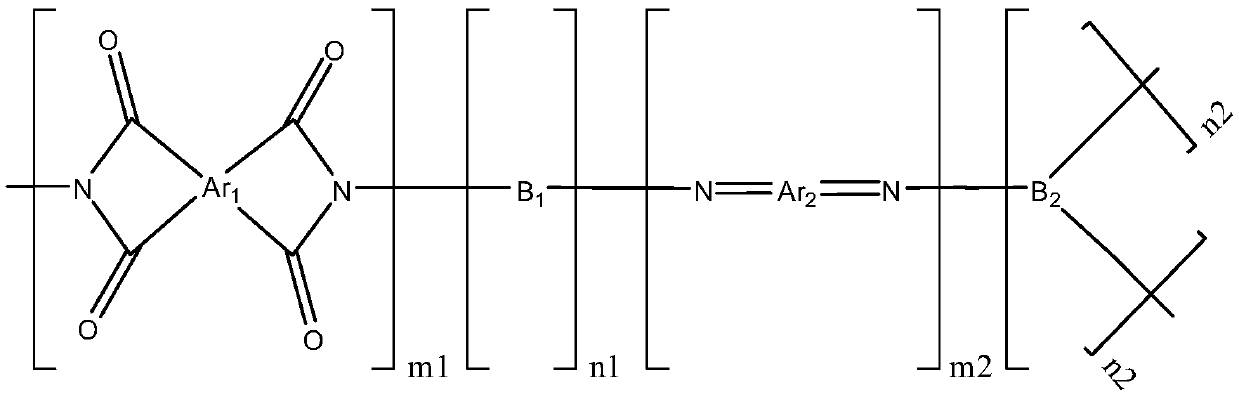

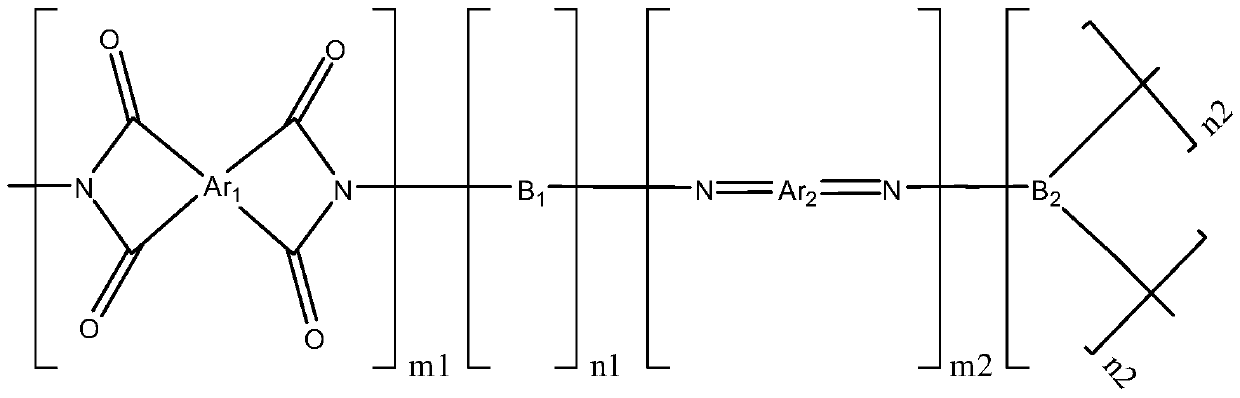

Low-dielectric-constant polyimide composite resin as well as preparation method and application thereof

A technology of low dielectric constant and polymethylimide resin, which is applied in the direction of circuit substrate materials, printed circuit components, photosensitive materials used in optomechanical equipment, etc., and can solve the problems of low dipole moment and dielectric constant reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

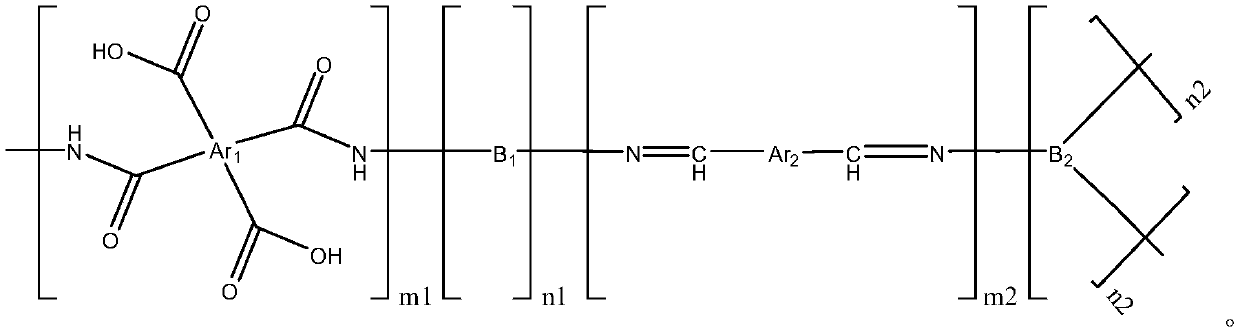

Method used

Image

Examples

Embodiment 1-20

[0081] [Polyimide Composite Resin A-T] was prepared according to the input amount of raw materials in Table 1 and the following experimental procedures:

[0082] Under a nitrogen atmosphere, in a 100mL three-necked flask, dissolve the quantitative diamine compounds and triamine compounds shown in Table 1 in 40g of NMP while stirring, so that the sum of the mass percentages of the amine compounds is 5%-13 %. Then add the quantitative diformaldehyde compounds shown in Table 1, control the temperature of the solution at 0-50°C under nitrogen atmosphere, and react for 4-24h. Add the quantitative tetraformic acid dianhydride compound shown in table 1 three times afterwards in the solution, each addition accounts for 60%, 30%, 10% of total weight respectively; Continue to react 4-48h under nitrogen atmosphere, solution temperature Control at 0-50°C. Finally, the precursor solution of polyimide composite resin is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com