Polyimide precursor and polyimide

A polyimide precursor, chemical imidizing agent technology, applied in printed circuits, coatings, electrical components, etc., can solve the problems of reduced heat resistance, low temperature, etc., to achieve excellent performance, low linear thermal expansion coefficient, the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

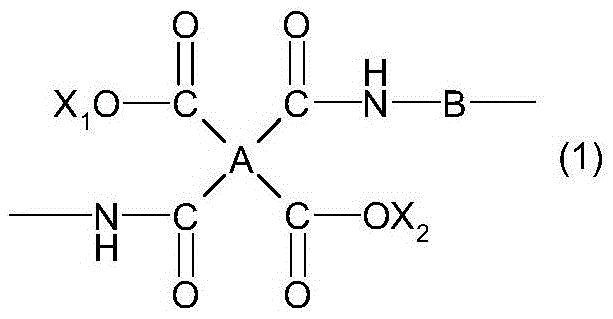

Method used

Image

Examples

preparation example Construction

[0116] For solvents used in the preparation of polyimide precursors, aprotic solvents such as N,N-dimethylformamide, N,N-dimethylacetamide, 1-methyl-2-pyrrolidone, 1- Ethyl-2-pyrrolidone, 1,1,3,3-tetramethylurea, 1,3-dimethyl-2-imidazolinone and dimethylsulfoxide are preferred, e.g. N,N-dimethyl Acetamide and 1-methyl-2-pyrrolidone are particularly preferred. However, any solvent may be used as long as the starting monomer components and the formed polyimide precursor can be dissolved in the solvent, and the solvent is not limited to the structure. Examples of preferred solvents employed include amide solvents such as N,N-dimethylformamide, N,N-dimethylacetamide, and 1-methyl-2-pyrrolidone; cyclic ester solvents such as γ-butyrol Esters, γ-valerolactone, δ-valerolactone, γ-caprolactone, ε-caprolactone and α-methyl-γ-butyrolactone; carbonate solvents such as ethylene carbonate and propylene carbonate; Glycol solvents such as triethylene glycol; phenolic solvents such as m-cre...

Embodiment 19

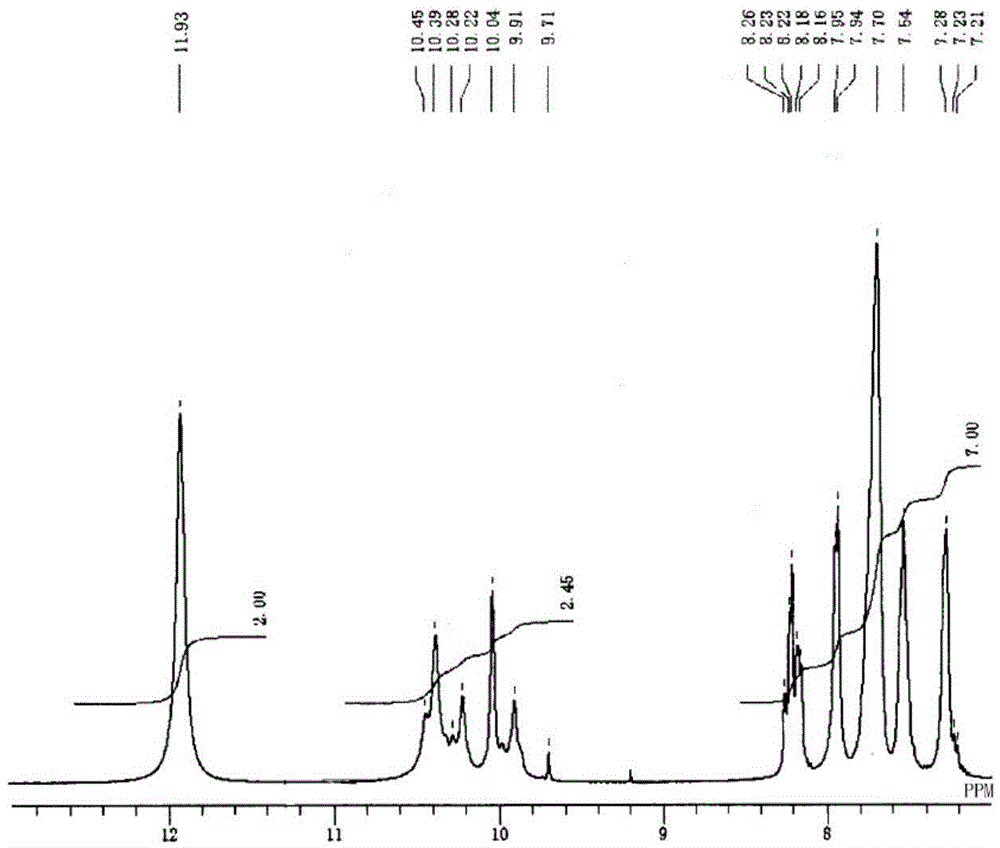

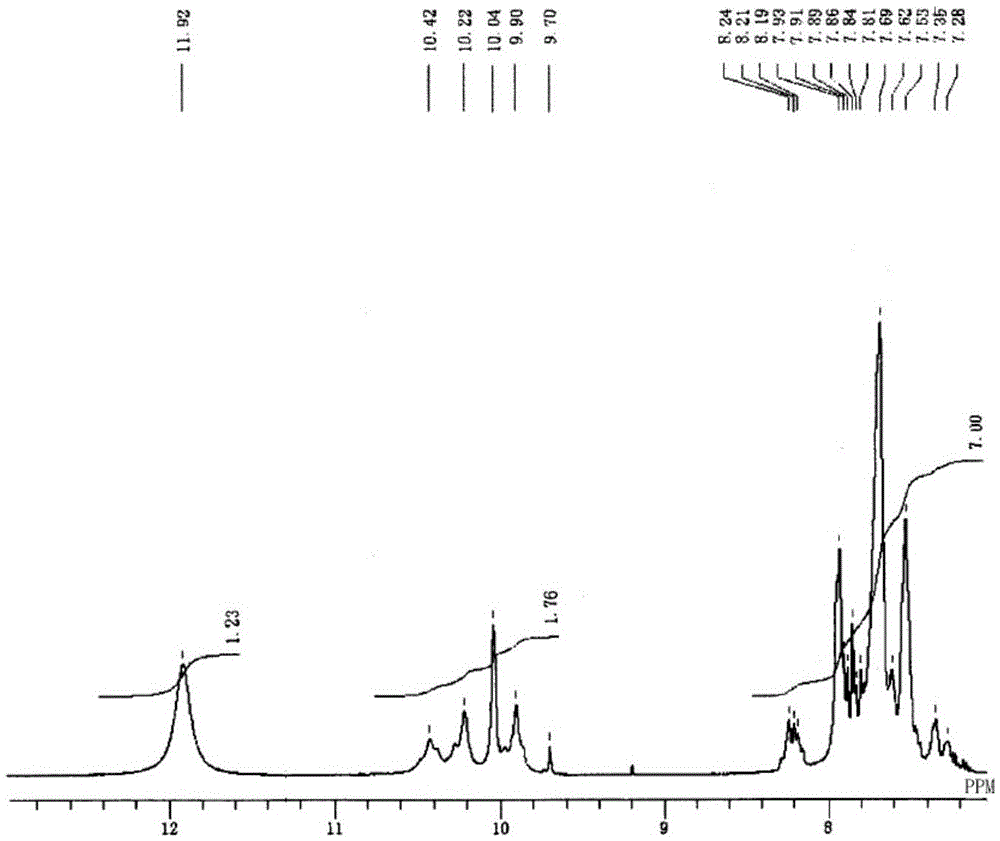

[0182] The degree of imidization of Example 19 was calculated by Equation (I) to be 38.5%.

[0183] Degree of imidization (%)=[1-(1.23 / 7)×{1 / (2 / 7)}]×100

[0184] =38.5

[0185]

[0186] [Light transmittance at 400nm, total light transmittance]

[0187] The light transmittance at 400 nm and the total light transmittance (average light transmittance from 380 nm to 780 nm) of the polyimide film having a thickness of about 10 μm were measured using MCPD-300 model produced by Otsuka Electronics Co., Ltd. Light transmittance and total light transmittance at 400 nm of a polyimide film having a thickness of 10 μm On the assumption that the reflectance is 10%, the light transmittance measured at 400 nm and the total light transmittance measured using the Lambert-Beer formula Calculated from transmittance.

[0188] log 10 ((T 1 +10) / 100)=10 / L×(Log 10 ((T 1 '+10) / 100))

[0189] log 10 ((T 2 +10) / 100)=10 / L×(Log 10 ((T 2 '+10) / 100))

[0190] T 1 : The light transmittance at...

Embodiment 1

[0221] The TFMB of 2.000g (6.246mmol) is placed in reaction vessel, it is purged with nitrogen gas, and the DMAc of 32.8g is added thereto so that the total weight of charged monomer (the total weight of diamine component and carboxylic acid component ) was 20% by weight, and the mixture was stirred at room temperature for 1 hour. 1.600 g (4.164 mmol) of CpODA was gradually added to the resulting solution, and the mixture was stirred at 50° C. for 5 hours. Subsequently, the mixture was heated to 160° C., and 25 mL of toluene was added thereto, and the toluene was refluxed for 3 hours, then the toluene was extracted, and the resulting solution was cooled to room temperature to provide a solution containing an imide compound. The degree of polymerization (n) of the imide compound is 2 calculated from the amount of charged monomers, and both terminals are amino groups. 1.419 g (6.246 mmol) of DABAN were added to the solution, and the mixture was stirred at room temperature for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com