Anisotropic conductive connector and wafer inspection device

An anisotropic and conductive technology, applied in the field of wafer inspection devices, can solve the problem of long distance of signal transmission system, and achieve the effect of maintaining stability, high conductivity and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

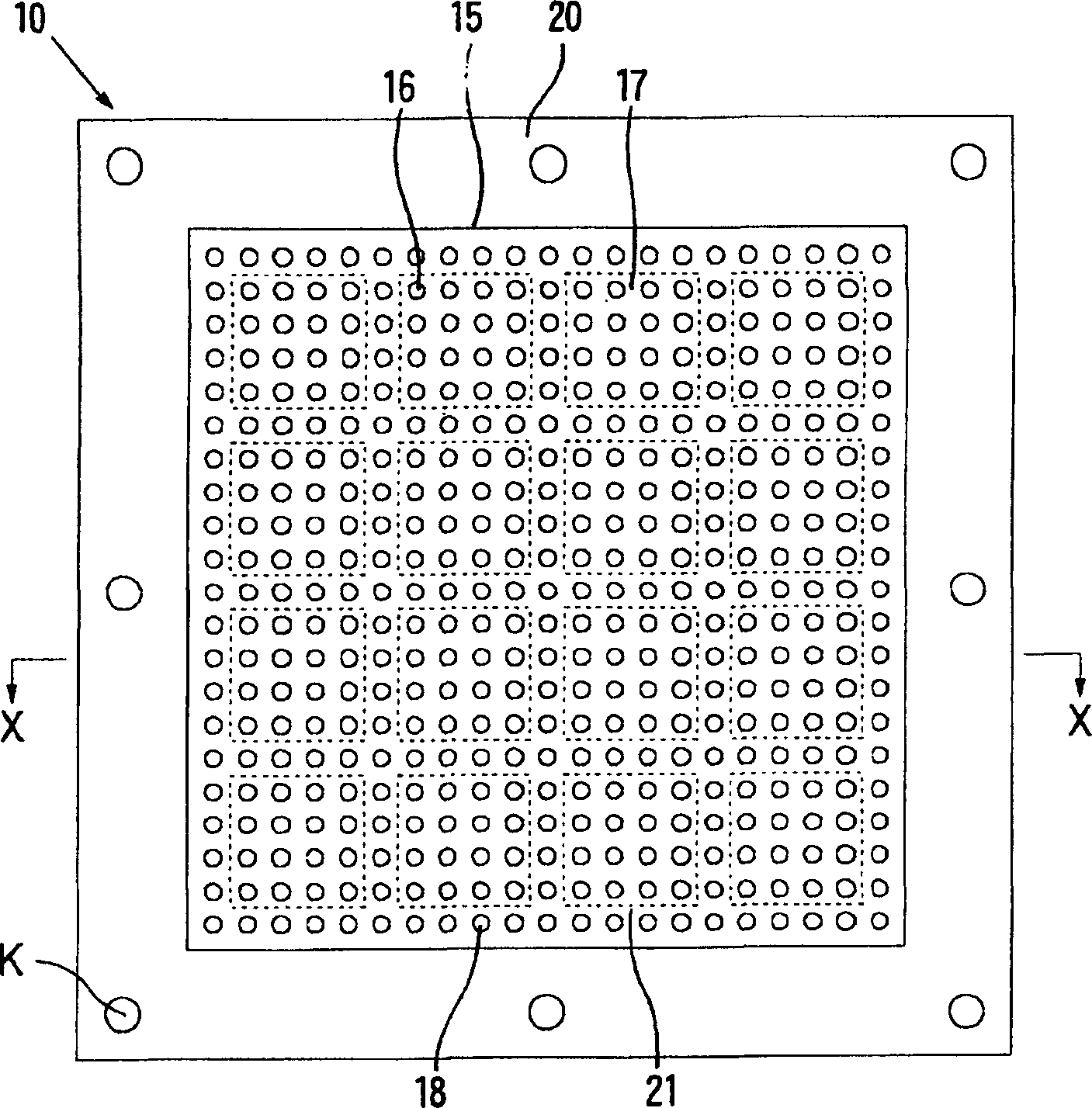

[0252] Prepare a brass plate with a thickness of 3.0mm, and drill holes in the X-X direction on one side of the non-magnetic material substrate (indicating the same as figure 1 The direction corresponding to the X-X direction shown. The same below) and the Y-Y direction (representing the direction perpendicular to the X-X direction. The same below) form a plurality of circular recesses with a diameter of 0.3mm and a depth of 2.7mm for accommodating magnetic components at a pitch of 0.8mm, and at the same time On the other side of the non-magnetic material substrate in the X-X direction and Y-Y direction, a plurality of recesses for forming protrusions with a diameter of 0.3 mm and a depth of 0.05 mm and a circular cross section are formed at a pitch of 0.8 mm. Substrate of non-magnetic material. In each magnetic member accommodation recess of the non-magnetic material substrate, a spherical magnetic member with a diameter of 0.3 mm made of iron is provided, and a cylindrical...

manufacture example 2

[0255] Prepare an iron plate with a thickness of 6mm, and use dry film photoresist and ferric chloride to perform photolithography on one side of the iron plate, so that the X-X direction on the ferromagnetic material substrate with a thickness of 5.9mm and made of iron Form a plurality of disc-shaped ferromagnetic material layers with a thickness of 0.1 mm and a diameter of 0.25 mm at a pitch of 0.65 mm in the Y-Y direction to form an intermediate body.

[0256] On one side of the intermediate body, on the region other than the ferromagnetic material layer, a non-magnetic material layer with a thickness of 0.15 mm is formed using a photoresist, thereby making an upper mold, and simultaneously making a lower mold in the same way. made Figure 7 Die for the structure shown. This mold is called "die b".

manufacture example 3

[0258] Prepare an iron plate with a thickness of 6mm, and use dry film photoresist and ferric chloride to perform photolithography on one side of the iron plate, so that the X-X direction on the ferromagnetic material substrate with a thickness of 5.9mm and made of iron A plurality of disc-shaped ferromagnetic material layers with a thickness of 0.1 mm and a diameter of 0.40 mm are formed at a pitch of 1.00 mm in the Y-Y direction to form an intermediate body.

[0259] On one side of the intermediate body, on the area other than the ferromagnetic material layer, a non-magnetic material layer with a thickness of 0.2 mm is formed using a photoresist, thereby making an upper mold, and at the same time making a lower mold by the same method, This makes Figure 7 Die for the structure shown. This mold is called "die c".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com