Polyamide-imide solution and polyamide-imide film

A polyamide-imide film, polyamide-imide technology, applied in synthetic resin layered products, transportation and packaging, coating and other directions, can solve the problems of surface deterioration, high problem, easy moisture absorption, etc. Effects of low coefficient of linear thermal expansion and excellent coatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] (Evaluation method)

[0107] The material property values and the like described in this specification were obtained by the following evaluation methods.

[0108] (1) Molecular weight of polyamideimide

[0109] The weight average molecular weight (Mw) was calculated|required under the conditions of Table 1. The evaluation results are shown in Table 3.

[0110] [Table 1]

[0111]

[0112] (2) Solubility test of polyamideimide in organic solvent and odor evaluation of organic solvent

[0113] For 0.5 g of polyamideimide obtained in Synthesis Examples 1, 2 and 3, 9.5 g of organic solvents (solid content concentration 5%) recorded in Table 2 were mixed in a sample tube, and the mixture was stirred at room temperature with a magnetic stirrer. Stir at 23 °C. The case of complete dissolution was marked as ◯, the case of partially dissolved and remained was marked as △, and the case of insoluble was marked as ×. Table 2 shows the solvents used, their boiling points, ...

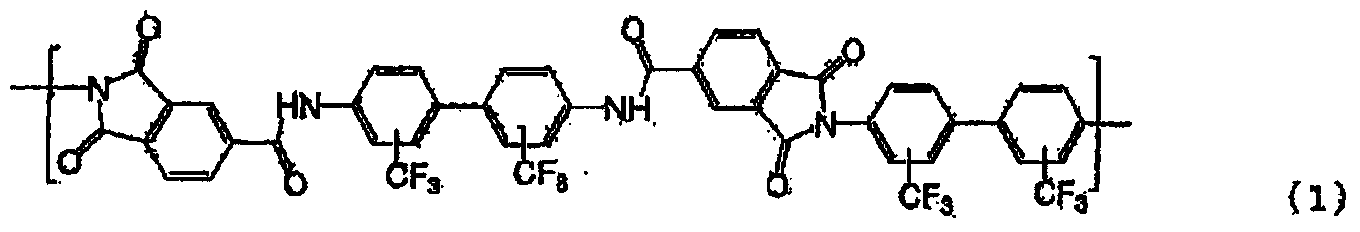

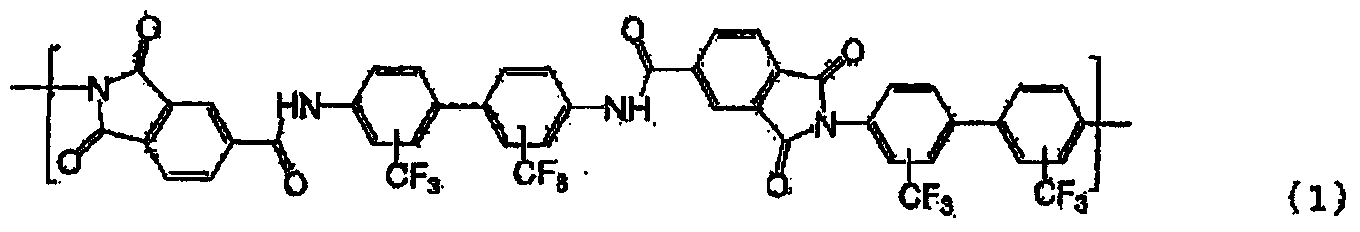

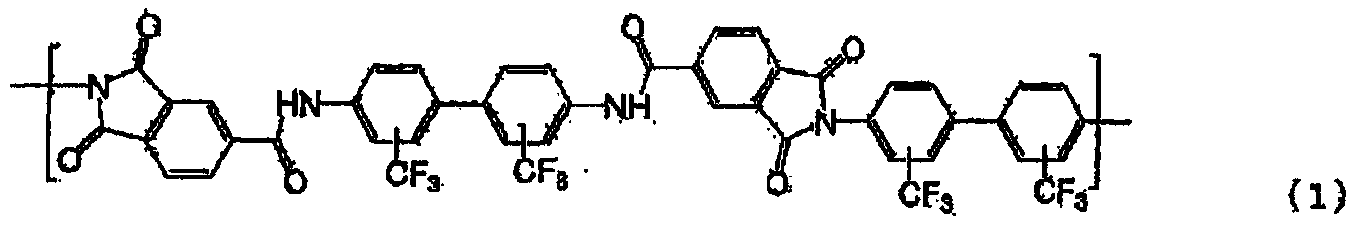

Synthetic example 1)

[0127]

[0128] 2,2'-bis(tri Fluoromethylmethyl)benzidine (hereinafter sometimes referred to as TFMB.) 12.1g, as a polymerization solvent, added 46.6g of dehydrated N,N-dimethylacetamide (DMAC) and stirred, then added 3.0g of pyridine, And stir until uniform, and cool with an ice bath at 5°C. While stirring this solution, 7.9 g of chlorinated trimellitic anhydride was slowly added in a powder state, and stirred in an ice bath at 5°C for 3 hours. In addition, the feed concentration of diamine compound and chlorinated trimellitic anhydride, which are solutes in this solution, was 30% by weight relative to the entire reaction liquid.

[0129] After stirring for 3 hours, 33.4 g of DMAC was added to the above solution to dilute, and after stirring for another 20 hours in a water bath at 25°C, 33.3 g of DMAC was added and stirred until uniform, and then 6.0 g of pyridine was added as an imidization catalyst. Make it completely dispersed. After adding and stirring 9.2 g of aceti...

Embodiment 1)

[0131]

[0132] The polyamideimide obtained in Synthesis Example 1 was dissolved in a mixed solvent with a weight ratio: DMAC / cyclopentanone (hereinafter referred to as CPN) = 70 / 30, and a polyamideimide containing 7% by weight of polyamideimide was produced. The amidoimide solution was applied on a glass plate as a support, and then dried at 60° C. for 10 minutes, then at 150° C. for 60 minutes, and at 300° C. for 60 minutes. The film was then peeled off from the glass plate to obtain a film. Table 3 shows the evaluation results of the obtained films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com