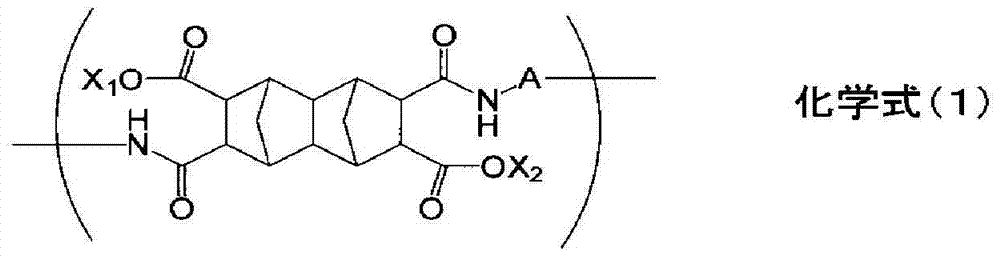

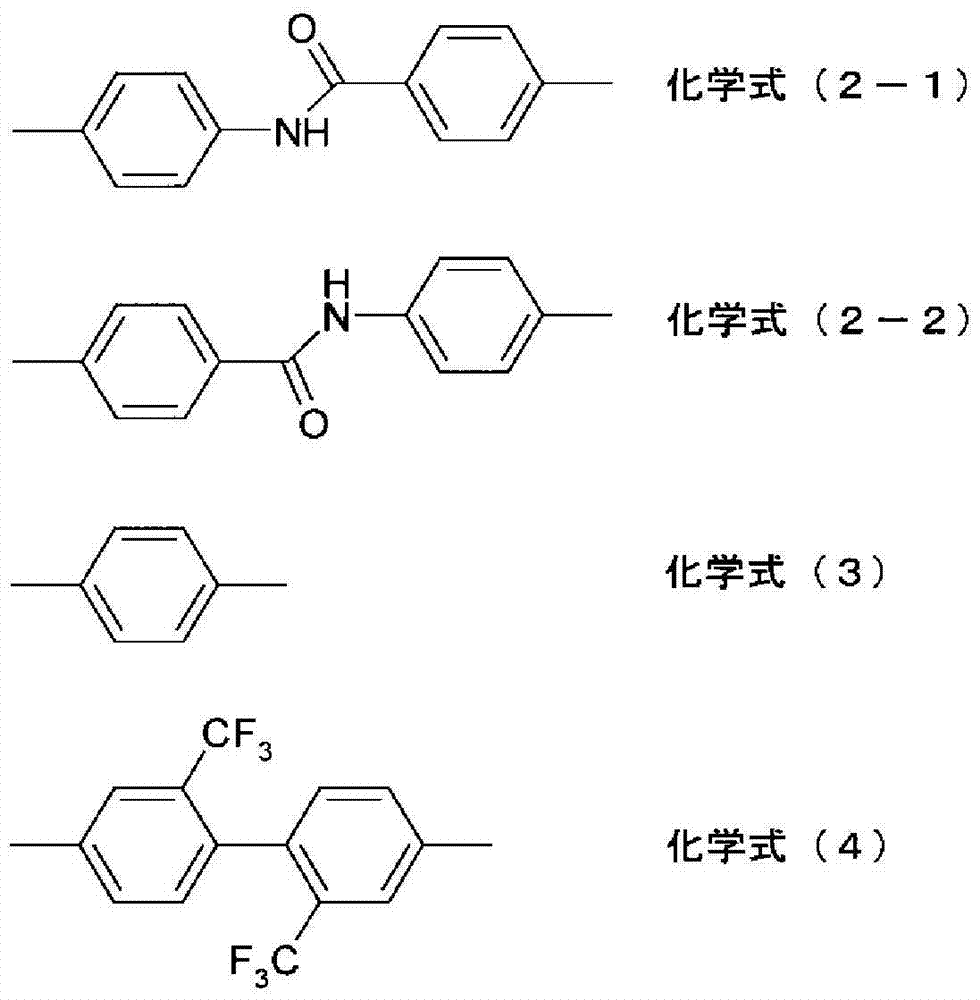

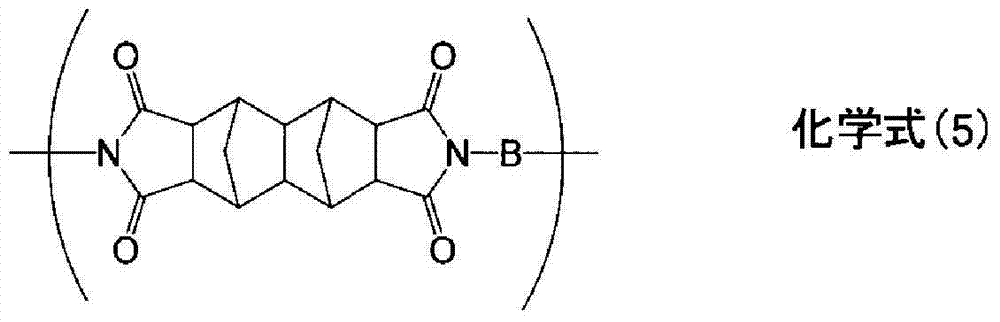

Polyimide precursor, polyimide, varnish, polyimide film, and substrate

A polyimide precursor, polyimide film technology, applied in the direction of coating, can solve the problems of undocumented polyimide transparency or linear thermal expansion coefficient, etc., and achieve high heat resistance and high transparency , the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0177] Charge DABAN 0.68g (3 millimoles) and TFMB 2.24g (7 millimoles) in the reaction vessel that has been replaced with nitrogen, and add so that the feed total mass of monomer (diamine component and carboxylic acid group 23.79 g of N,N-dimethylacetamide in an amount of 20% by mass) was stirred at room temperature for 1 hour. To this solution was slowly added DNDAxx 3.02 g (10 mmol). After stirring at room temperature for 12 hours, a homogeneous and viscous polyimide precursor solution was obtained. The logarithmic viscosity of the obtained polyimide precursor was 0.5 dL / g.

[0178] Apply the polyimide precursor solution filtered with a PTFE membrane filter on a glass substrate, and heat it directly on the glass substrate from room temperature to 430°C under a nitrogen atmosphere (oxygen concentration: 200ppm or less). By imidization, a colorless and transparent polyimide film / glass laminate was obtained. Next, the obtained polyimide film / glass laminate was immersed in wa...

Embodiment 2

[0181] Charge DABAN 1.14g (5 millimoles) and TFMB 1.60g (5 millimoles) in the reaction vessel that has been replaced with nitrogen, and add so that the feed total mass of monomer (diamine component and carboxylic acid group 23.04 g of N,N-dimethylacetamide in an amount of 20% by mass) was stirred at room temperature for 1 hour. To this solution was slowly added DNDAxx 3.02 g (10 mmol). After stirring at room temperature for 12 hours, a homogeneous and viscous polyimide precursor solution was obtained. The logarithmic viscosity of the obtained polyimide precursor was 0.6 dL / g.

[0182] Apply the polyimide precursor solution filtered with a PTFE membrane filter on a glass substrate, and heat it directly on the glass substrate from room temperature to 430°C under a nitrogen atmosphere (oxygen concentration: 200ppm or less). By imidization, a colorless and transparent polyimide film / glass laminate was obtained. Next, the obtained polyimide film / glass laminate was immersed in wa...

Embodiment 3

[0185] Charge DABAN 1.59g (7 millimoles) and TFMB 0.96g (3 millimoles) in the reaction vessel that has been replaced with nitrogen, and add so that the feed total mass of monomer (diamine component and carboxylic acid group 22.30 g of N,N-dimethylacetamide in an amount of 20% by mass) was stirred at room temperature for 1 hour. To this solution was slowly added DNDAxx 3.02 g (10 mmol). After stirring at room temperature for 12 hours, a homogeneous and viscous polyimide precursor solution was obtained. The logarithmic viscosity of the obtained polyimide precursor was 0.5 dL / g.

[0186] Apply the polyimide precursor solution filtered with a PTFE membrane filter on a glass substrate, and heat it directly on the glass substrate from room temperature to 430°C under a nitrogen atmosphere (oxygen concentration: 200ppm or less). By imidization, a colorless and transparent polyimide film / glass laminate was obtained. Next, the obtained polyimide film / glass laminate was immersed in wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com