Polyamide-imide, polyamide-imide film and display device

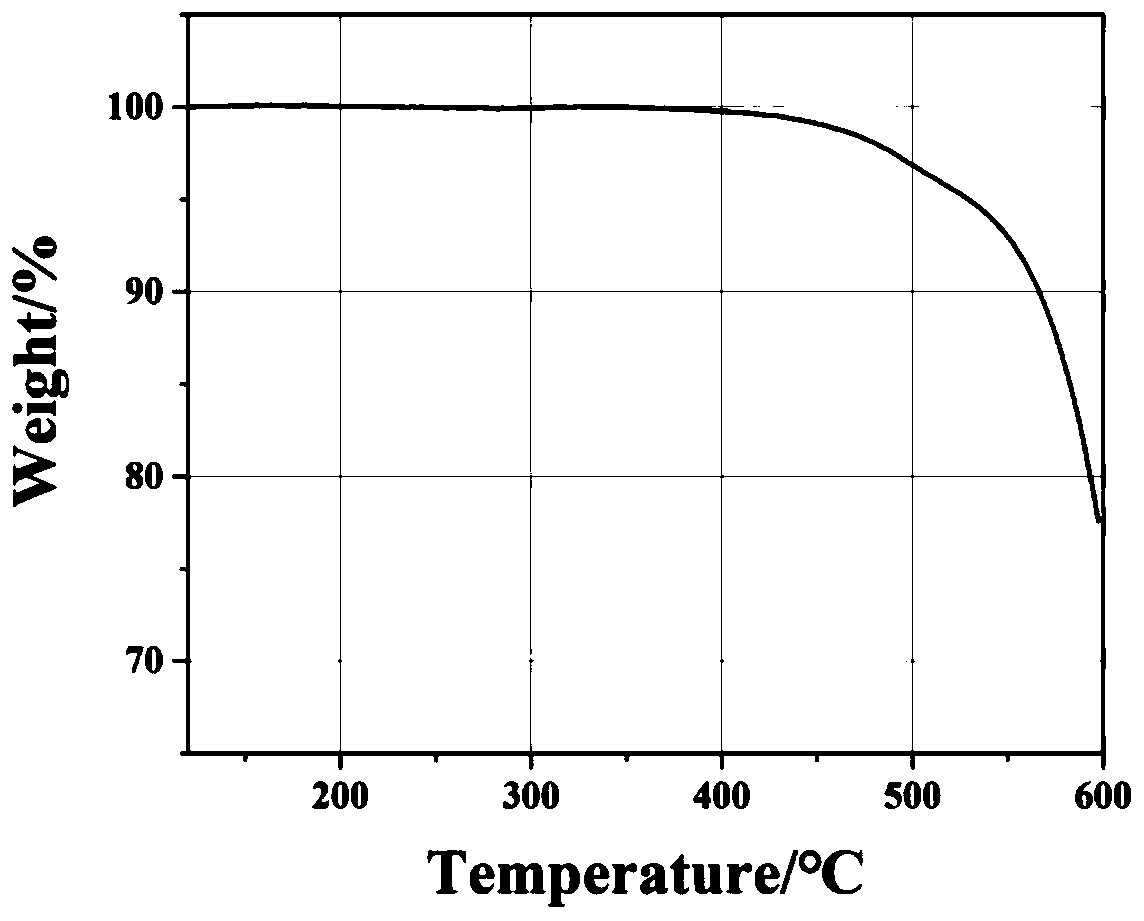

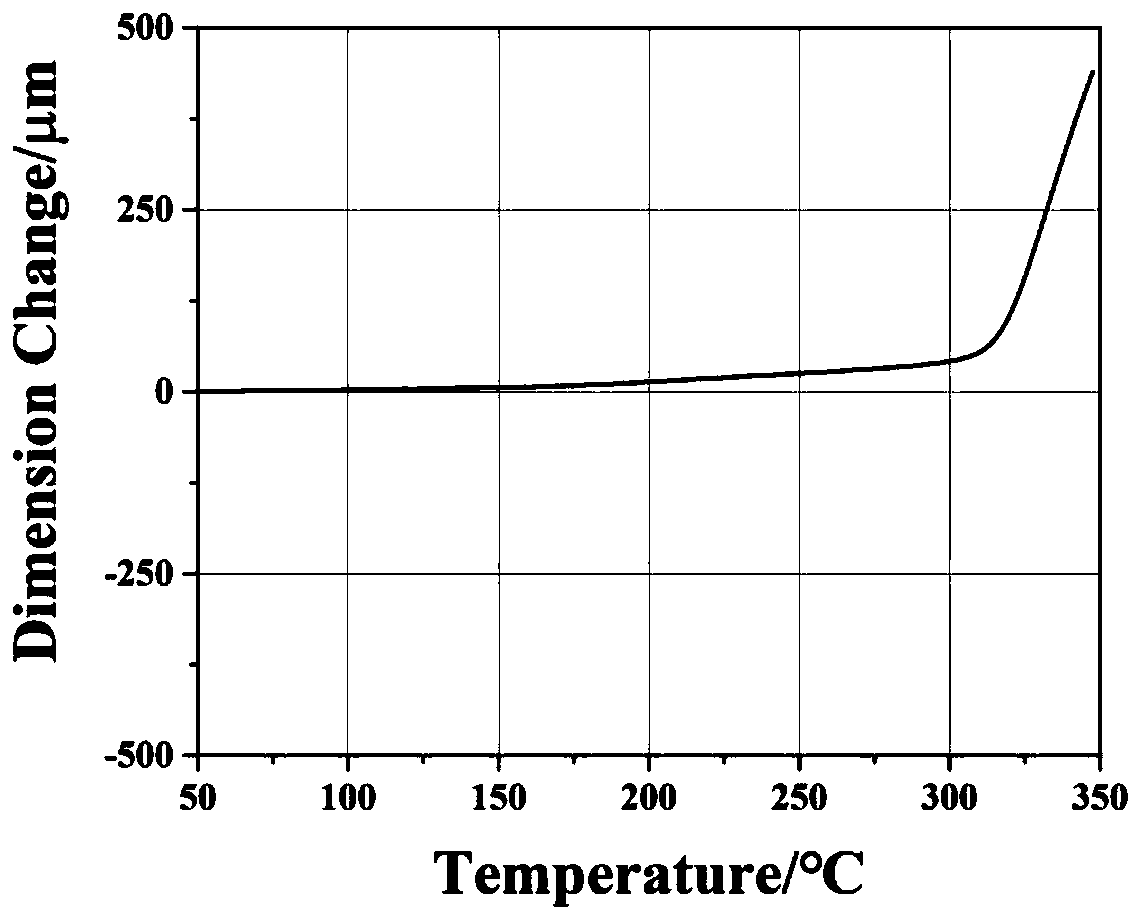

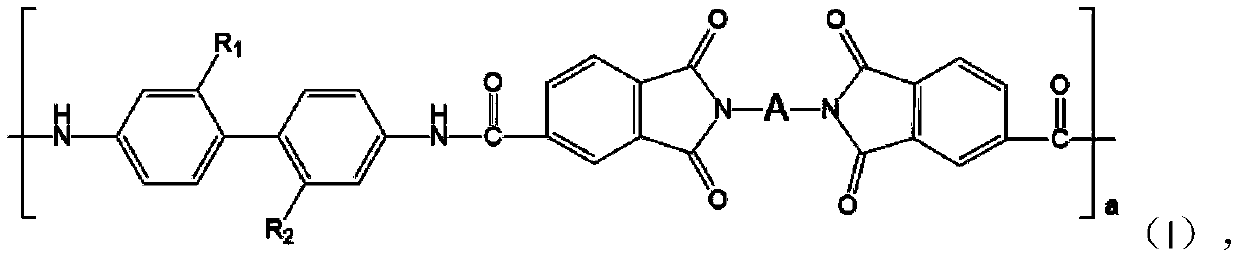

A polyamide-imide and film technology, applied in the field of polyamide-imide film and polyamide-imide, can solve the problems of low linear thermal expansion coefficient, poor material solubility, and limited linear thermal expansion coefficient, etc. Good solubility and heat resistance, low coefficient of thermal expansion properties, effect of low coefficient of linear thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] In a 1000mL reactor equipped with a stirrer, nitrogen injector, dropping funnel, temperature controller and condenser, add 500g of N-methylpyrrolidone (NMP) while blowing nitrogen, and dissolve 16.012g (0.05mol ) of TFMB. Subsequently, 32.9 g (0.06 mol) of DA-1 was added, 25.1 g of CaCl 2 , 83.4ml of triphenylphosphine, 83.4ml of pyridine, the reaction was heated to 100°C for 8h, and then 1.76g (0.01mol) of 35DBTF was added, and NMP solvent was added gradually, and the reaction was continued for 8h. After the reaction, the liquid was poured into 3000mL of rapidly stirring methanol, the product was filtered and washed, and dried overnight at 180°C under vacuum. The solid was re-dissolved with NMP to form a 10% polyamideimide solution.

[0109] After the reaction, the obtained solution was coated on a glass plate, cast to 100 μm to 300 μm, dried at 80°C for 20 minutes under vacuum, at 120°C for 20 minutes, and at 300°C for 10 minutes at a constant temperature, and slowl...

Embodiment 2~11

[0111] By adopting the same process as in Example 1 and selecting different monomers of the first block, the second block and the third block, polyamide-imide films with different effects can be obtained. The raw materials and usage amounts of each monomer are summarized in Table 2, wherein the amounts of all materials are molar amounts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com