Coloring agent composition for wood lacquer as well as preparation method and coating and construction method thereof

A coloring agent and composition technology, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problems of difficult operation, difficult coloring uniformity, poor construction effect, etc., and achieve strong construction tolerance and flow Excellent flatness and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a kind of preparation method of wood paint colorant composition, comprising:

[0056] Uniformly mix the matrix resin with the wetting and dispersing agent and solvent system (esters, ketones, aromatic hydrocarbons, alcohol ethers, alcohol solvents) to obtain a pre-dispersed mixture;

[0057] Stir and disperse the above pre-dispersed mixture and the metal complex dye evenly to obtain a colorant resin composition.

[0058] According to the invention, it is also optional to add defoamers and leveling agents to the mixture. It is also optional to stir and disperse the mixture for 5-10 minutes; then disperse the mixture in the mixed solvent for the second time, and the time for the second dispersion is preferably 5-8 minutes. A uniformly dispersed resin composition is obtained without delamination and bubbles.

[0059] The present invention also provides a coating construction method of the wood lacquer colorant composition, comprising: ...

Embodiment 1

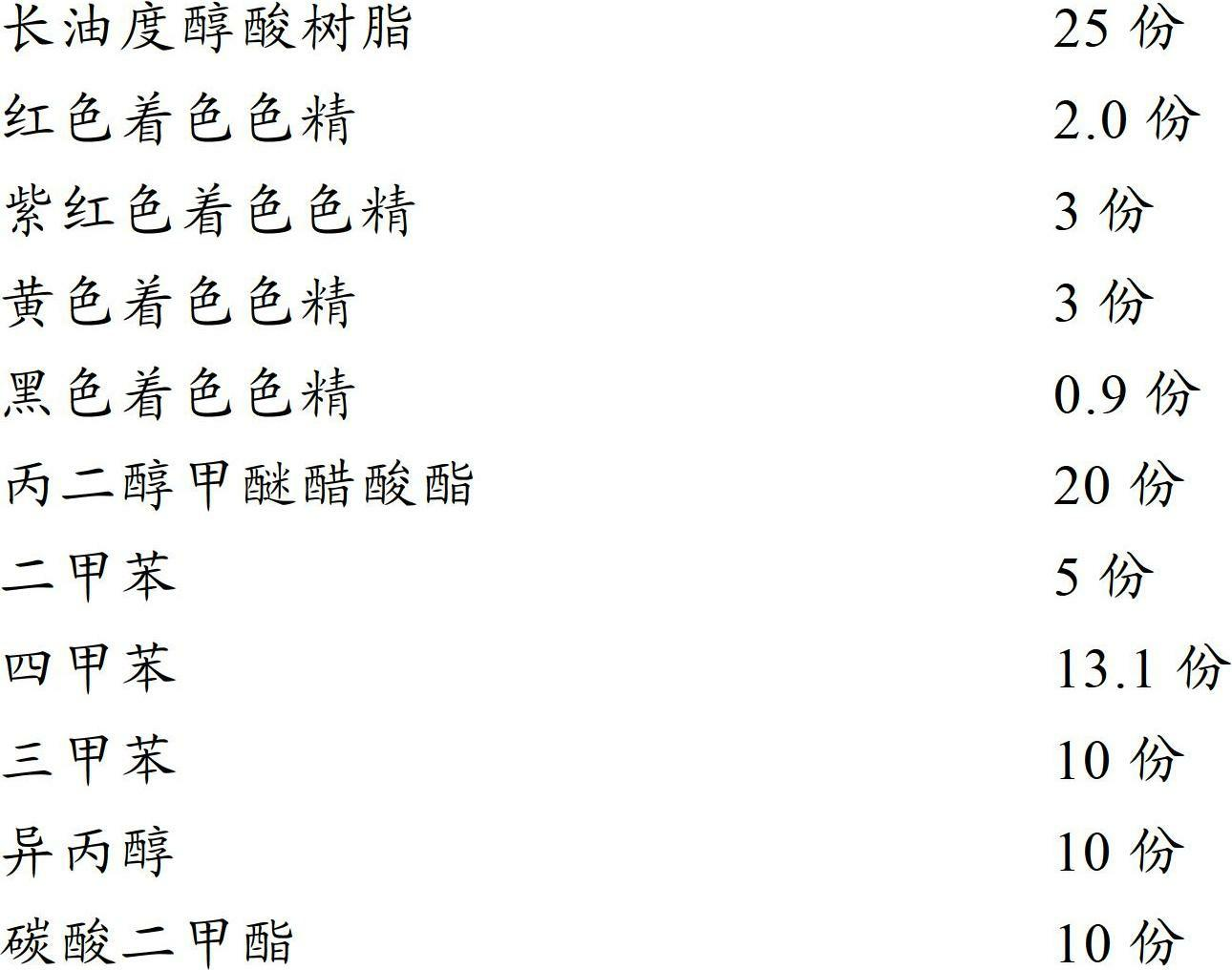

[0072] Mahogany-colored hand-sweeping coloring agent, according to the weight percentage, mainly has the following ratio composition;

[0073]

[0074]

[0075] Long oil alkyd resin, the solid content of the resin is >98wt%, and the color is light yellow liquid;

[0076] Specific steps: Add long-oil alkyd resin, defoamer, leveling agent, and wetting and dispersing agent into the container, stir at a medium speed for 5-10 minutes, and then add xylene, trimethylbenzene, tetramethylbenzene, and propylene glycol methyl ether in sequence Acetate, cyclohexanone, dimethyl carbonate, isopropanol and other solvents, stir at a medium speed for 5 minutes, then add the corresponding proportion of black, red, yellow or purple color essence to the above dispersion, and disperse for 5-8 minutes. get the product;

[0077] Apply the colorant composition prepared in this embodiment on the polyester paint substrate according to claim 13, the coloring time is 5-10min, spray or brush the po...

Embodiment 2

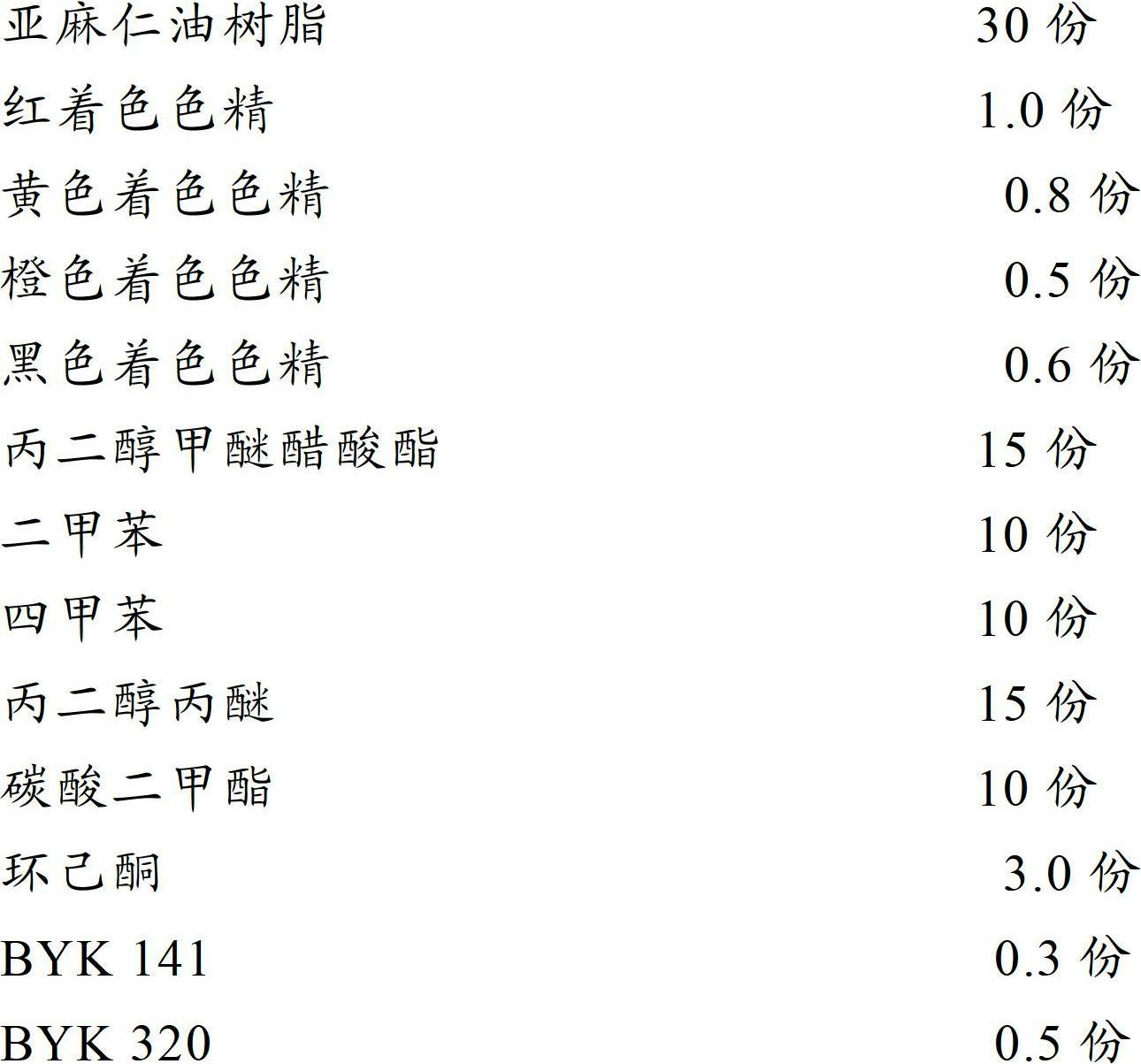

[0079] The reddish-brown hand-sweeping coloring agent mainly consists of the following ratios according to the percentage by weight;

[0080]

[0081]

[0082] Linseed oleoresin, resin solid content is 100wt%, color is light yellow liquid;

[0083] Specific steps:

[0084] Add linseed oleoresin, defoamer, leveling agent, and wetting and dispersing agent into the container, stir at a medium speed for 5-10 minutes, and then add xylene, trimethylbenzene, tetramethylbenzene, propylene glycol methyl ether acetate, and cyclohexane in sequence Ketone, dimethyl carbonate, propylene glycol propyl ether and other solvents, stir at a medium speed for 5 minutes, then add the corresponding proportion of black, red, yellow or orange color essence to the above pre-dispersion, disperse for 5-8 minutes to obtain the product;

[0085] Apply the colorant composition prepared in this embodiment on the polyester paint substrate according to claim 13, the coloring time is 5-10min, spray or b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com