Inkjet ink and printing methods

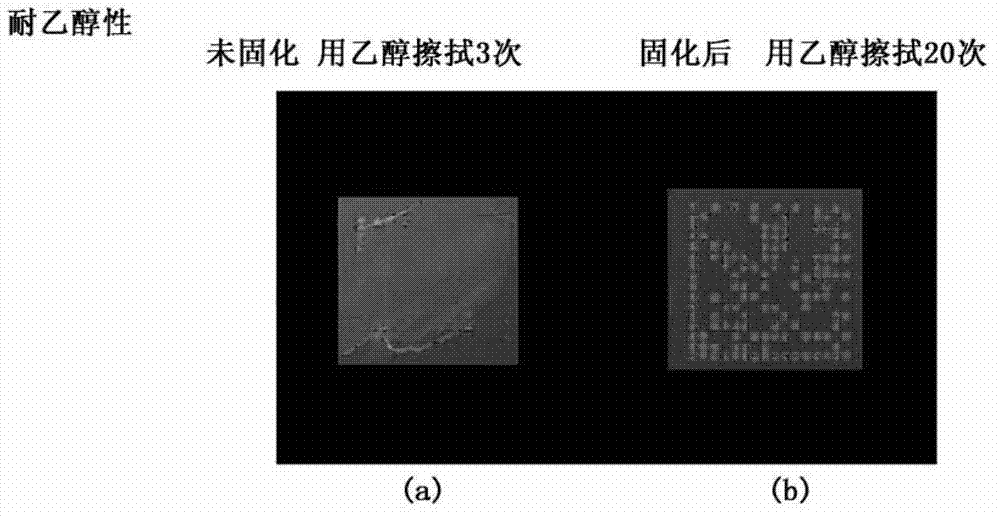

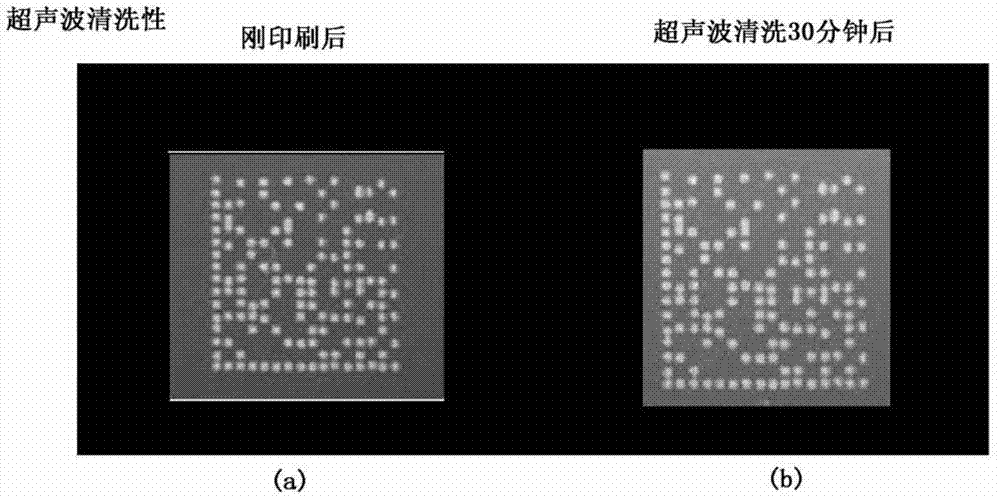

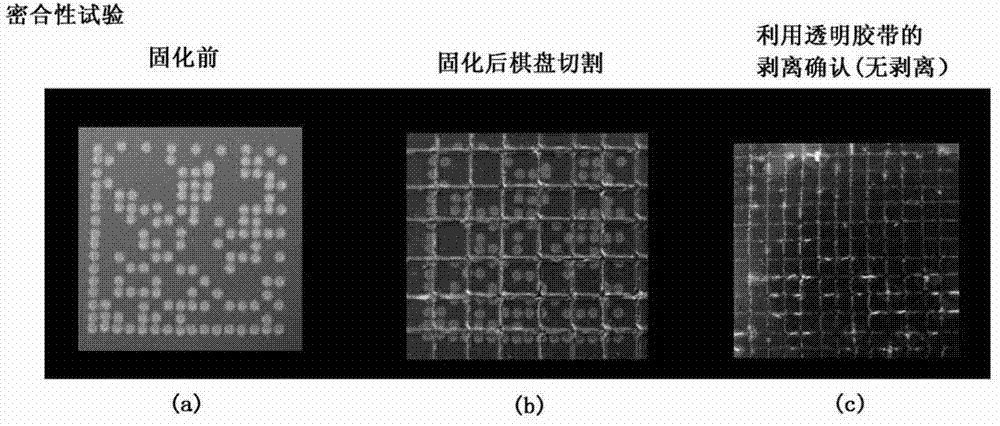

An inkjet printing machine and ink technology, applied in printing, ink, copying/marking methods, etc., can solve the problems of inability to apply ink, etc., and achieve the effects of simple composition, excellent ejection stability, and excellent resolubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Butyral resin (molecular weight = 19000, hydroxyl group content = 36%, acetyl group content = 3%, butyralization degree 63%) 4.2 parts by weight, Solspray 24000 (dispersant: manufactured by Lubrizol Corporation) 0.5 parts by weight, 0.2 parts by weight of Solspray 5000 (dispersant: manufactured by Lubrizol Corporation), and 10 parts by weight of rosin-modified maleic acid resin were dissolved in 79.2 parts by weight of methyl ethyl ketone to form a solution, and 4.2 parts by weight of carbon black (REGAL330R: manufactured by Cabot Corporation) was added to this solution and stirred to obtain a mixed solution, which was supplied to a horizontal sand mill to disperse carbon black. 1 part by weight of blocked isocyanate using dimethylpyrazole as a blocking agent was added to the dispersion and mixed, and 0.7 part by weight of tetrabutylammonium hexafluorophosphate was added, followed by high-speed stirring and mixing. Thereafter, the mixed dispersion liquid was filtered th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com