Waterborne polyurethane dispersion with high performance and preparation method thereof

A water-based polyurethane and dispersion technology, applied in the field of new chemical materials, can solve the problems of solvent green recycling production efficiency, inability to achieve low modulus, high tensile strength, low molecular weight, etc., to reduce equipment requirements, improve production efficiency, The effect of increasing the molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

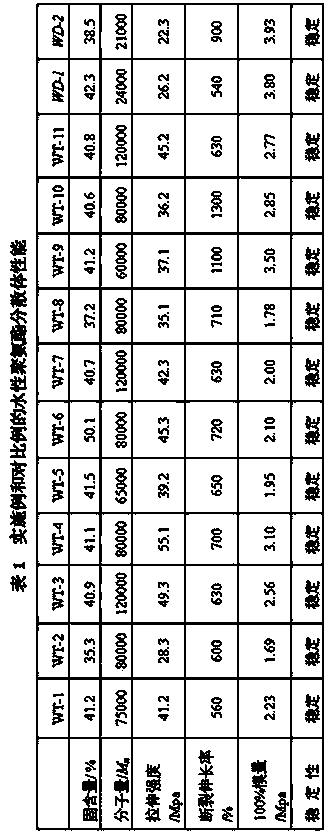

Examples

Embodiment 1

[0080] Example 1 (WT-1)

[0081] The A component PTMEG1000, B component MDI and C component BDO are heated to 100, 60, 80 ℃ respectively, and 40ppm of Dabco is added to the A component T-9, 0.2%wt Irganox1010, 0.2%wt Irgafos168, 0.4%wt Tinuvin 329, 0.4%wt Tinuvin 292; DMBA with 1.31 times the mass of BDO was added to the C component, and the above three components were fully melted and maintained after the The temperature is 80, 60, 60 ℃;

[0082] The three components A, B, and C are introduced into a 140-180 ℃, 200 rpm after the proportion of 57.7%wt, 33.4%wt, 8.9%wt is accurately measured by a metering pump and a flowmeter, and is instantly mixed by a high-speed mixing head. After the reaction type twin-screw extruder reacts for 2 minutes, the water-based polyurethane particles are obtained by underwater dicing and collection;

[0083] Put 2000Kg of the above-mentioned water-based polyurethane particles into a mixture containing 5000Kg of acetone / water (mass ratio 3:2), t...

Embodiment 2

[0084] Example 2 (WT-2)

[0085] Raise the temperature of A-component PPG 2000, B-component MDI and C-component BDO to 50, 60, and 100°C respectively, and add 50ppm of Dabco to A-component T-9, 0.2%wt Irganox1010, 0.2%wt Irgafos168, 0.4%wt Tinuvin 329, 0.4%wt Tinuvin 292; add DMBA 1.31 times the mass of BDO to component C, and keep the above three components fully melted and uniform Temperature at 50, 60, 80°C;

[0086] The three components of A, B and C are accurately metered by metering pump and flow meter at the ratio of 64.5%wt, 26.7%wt and 8.8%wt, and then mixed evenly by the high-speed mixing head, and then introduced into the 120-160℃, 300rpm The reactive twin-screw extruder reacted for 3 minutes and pelletized and collected under water to obtain water-based polyurethane particles;

[0087] Put 2000Kg of the above-mentioned water-based polyurethane particles into 7000Kg of acetone / water mixture (mass ratio 1:1.2), then add 67.8 Kg of TEA, raise the temperature to 70°...

Embodiment 3

[0088] Example 3 (WT-3)

[0089] Raise the temperature of A-component PBA 2000, B-component MDI and C-component BDO to 90, 60, and 100°C respectively, and add 20ppm of Dabco to A-component T-9, 0.2%wt Irganox1010, 0.2%wt Irgafos168, 0.4%wt Tinuvin 329, 0.4%wt Tinuvin 292; add DMBA 1.31 times the mass of BDO to component C, and keep the above three components fully melted and uniform Temperature at 50, 60, 80°C;

[0090] The three components of A, B and C are accurately metered by metering pump and flow meter at the ratio of 64.5%wt, 26.7%wt and 8.8%wt, and then mixed evenly by the high-speed mixing head, and then introduced into the 160-220℃, 200rpm The reactive twin-screw extruder reacted for 1 minute, and then pelletized and collected under water to obtain water-based polyurethane particles;

[0091] Put 2000Kg of the above-mentioned water-based polyurethane particles into 7000Kg of acetone / water mixture (mass ratio 1:1), then add 67.8 Kg of TEA, raise the temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com