Bonding adhesive for bonding fluorocarbon silicone rubber with metals and preparation method thereof

A fluorosilicone rubber and metal bonding technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc. difficulty of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0039] In an environment with an air humidity of 50-60%, at room temperature, according to the ratio of each component shown in Table 5, according to component A + component D, E, sealed and parked for 1 to 2 days, then + component C sealed and parked After 1-2 days, mix and prepare the adhesive of the present invention in the order of + component B, and keep it sealed for use.

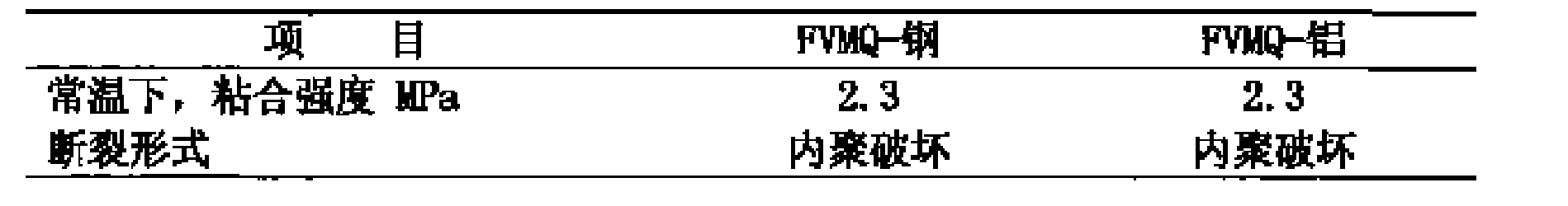

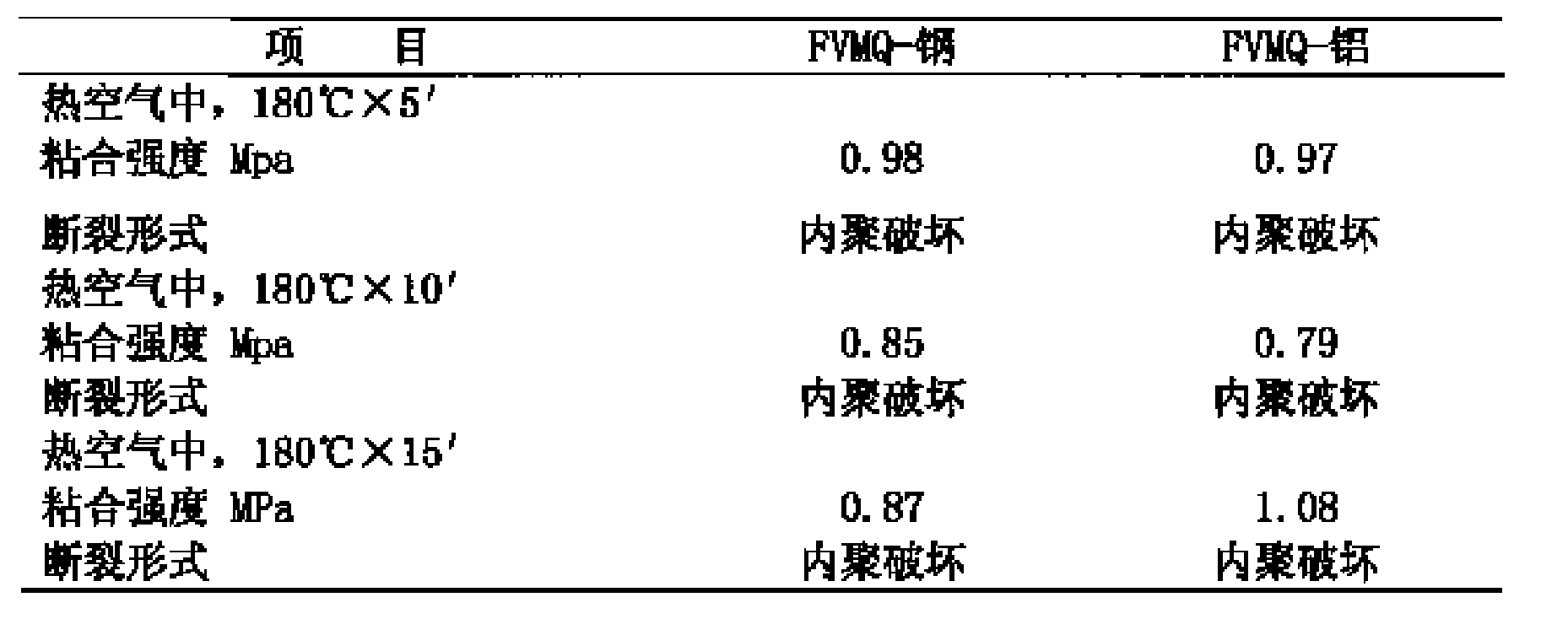

[0040] According to the provisions of GB / T11211-1989, the G402 fluorosilicone rubber compound produced by the Shanghai Rubber Products Research Institute and the No. 45 steel "fungus-shaped" test piece that has been sandblasted and cleaned and degreased with acetone are used to prepare the test piece for the determination of the bonding strength. The adhesive strength measured after vulcanization according to the specified process is shown in Table 5. It can be seen from Table 5 that the adhesives of the present invention can meet the requirements for use, that is, the adhesive strength (at room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com