Natural yeast bread dough and manufacturing method thereof

A technology of natural yeast and bread dough, applied in the field of natural yeast, which can solve the problems of difficulty in proofing bread, thick bread skin, insufficient gas production, etc., and achieve the effect of difficult proofing, golden skin color and uniform internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

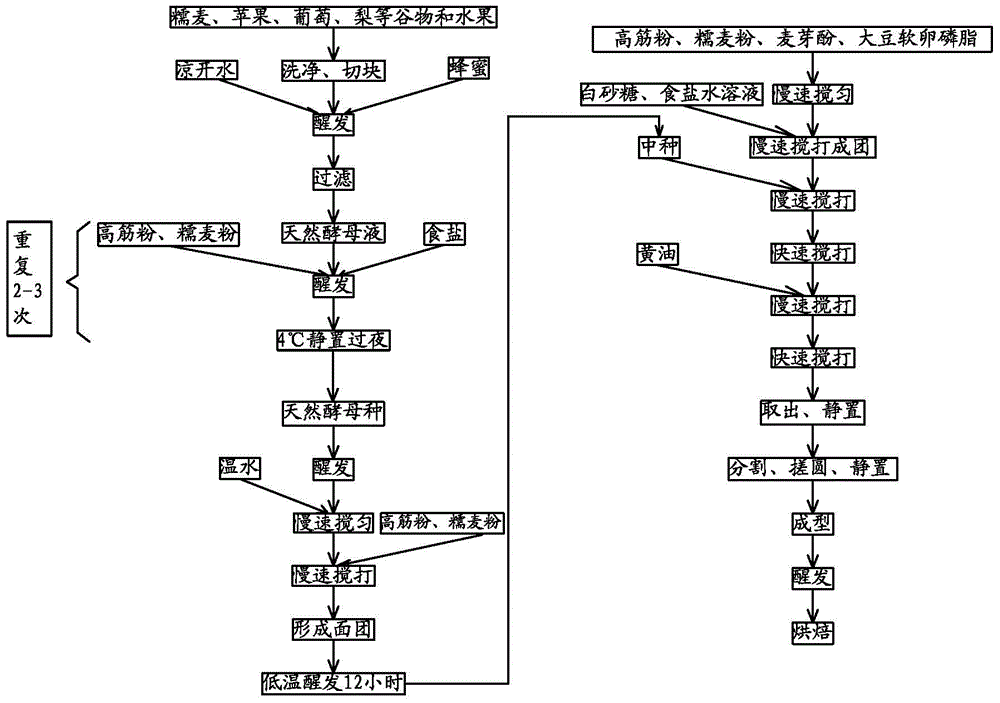

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of natural yeast liquid

[0033] The raw materials of natural yeast liquid are mainly fruits and grains containing at least glutinous wheat, and the ratio of fruits and grains is 2:1. Fruits can choose pears, apples, grapes, oranges, peaches, cherries, dragon fruit, longan, pipa and so on. Fruits and cereals are collectively referred to as fruits, and these fruits can be selected according to the season. Waxy wheat can also be fermented with a little barley and other grains.

[0034] Wash the fruits and grains and put them directly into high-temperature sterilized glass bottles, or cut the fruits with belt cores into pieces and put them into glass bottles. Pour in cold boiled water, the amount of water is enough to submerge the fruit or fruit pieces, and a space needs to be left above the water to fill the bottle with air for the bacteria to ferment. Add 5-8% honey before proofing or during proofing to promote the growth of bacteria. After stirring ev...

Embodiment 2

[0053] 1. Preparation of natural yeast liquid

[0054] As in step 1 of preparing natural yeast liquid in Example 1, add 8% honey to the raw material of natural yeast liquid. The proofing temperature is 28°C, 30°C, 31°C, 32°C, let it stand for 7 days, shake the glass bottle twice a day, observe the bubbles in the glass bottle disappear and give off a fruity fragrance and alcohol smell, and the natural yeast can be filtered out liquid.

[0055] 2. Preparation of natural yeast species

[0056] As in step 2 of the preparation of natural yeast species in Example 1, the mixed powder and natural yeast liquid are mixed at a ratio (m / m) of 1:1 or 1.1:1, and the proofing temperature is 28°C. Then, the same process of proofing and standing overnight in the refrigerator was repeated 3 times to obtain natural yeast species.

[0057] 3. Prepare the Chinese dough

[0058] As in step 3 of the preparation of the middle dough in Example 1, when the natural yeast is proofed, the temperature ...

Embodiment 3

[0068] 1. Preparation of natural yeast liquid

[0069] As in step 1 of the preparation of natural yeast liquid in Example 1, the glass bottle was placed in a proofing box at 28°C for 7 days, and the glass bottle was shaken 3 times a day to observe the disappearance of the bubbles in the glass bottle and the fragrance of fruit and alcohol. The natural yeast liquid can be obtained by filtration.

[0070] 2. Preparation of natural yeast species

[0071] As in step 2 of the preparation of natural yeast species in Example 1, the mixed powder and yeast liquid were mixed at a ratio of 1:1 (m / m), and the proofing temperature was 32°C. Then, the same process of proofing and standing overnight in the refrigerator was repeated 3 times to obtain natural yeast species.

[0072] 3. Prepare the Chinese dough

[0073] As in the step 3 of the preparation of the medium dough in Example 1, the natural yeast is placed in a 32°C proofing box for about 30 minutes, and 25 parts of the natural yea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com