ZrO2-based all-ceramic dental implant and preparation method thereof

A technology of dental implants and ceramics, which is applied in the fields of medical science, prosthesis, tissue regeneration, etc., and can solve the problems of complex installation of metal-based dental implants, waste, high perforation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

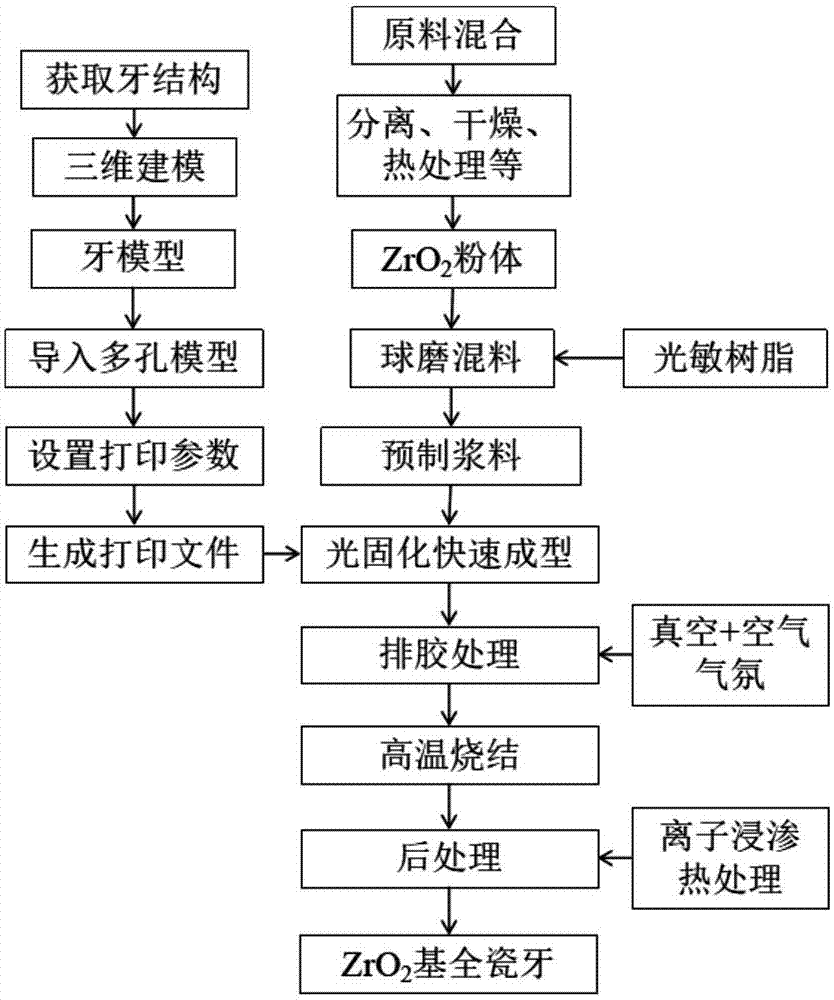

[0031] The invention provides a ZrO 2 A method for preparing a base all-ceramic implant, comprising the following steps:

[0032] Soluble zirconium salt, strong alkali and solution containing doping elements are prepared by nano-powder preparation technology to obtain nano-ZrO with stable doping elements 2 Powder;

[0033] The nano ZrO 2 The powder is mixed with the photosensitive resin to obtain a ceramic-photosensitive resin prefabricated slurry;

[0034] The ceramic-photosensitive resin prefabricated slurry is printed by additive manufacturing technology according to the simulated tooth model to obtain ZrO 2 ceramic green body;

[0035] The ZrO 2 Ceramic green body debinding and sintering to obtain ZrO 2 Ceramic substrate;

[0036] The ZrO 2 The ceramic matrix is subjected to ion infiltration, sintering and mineralization treatment to obtain ZrO 2 All-ceramic dental implants.

[0037] The present invention makes the prepared ZrO by adopting additive manufacturin...

Embodiment 1

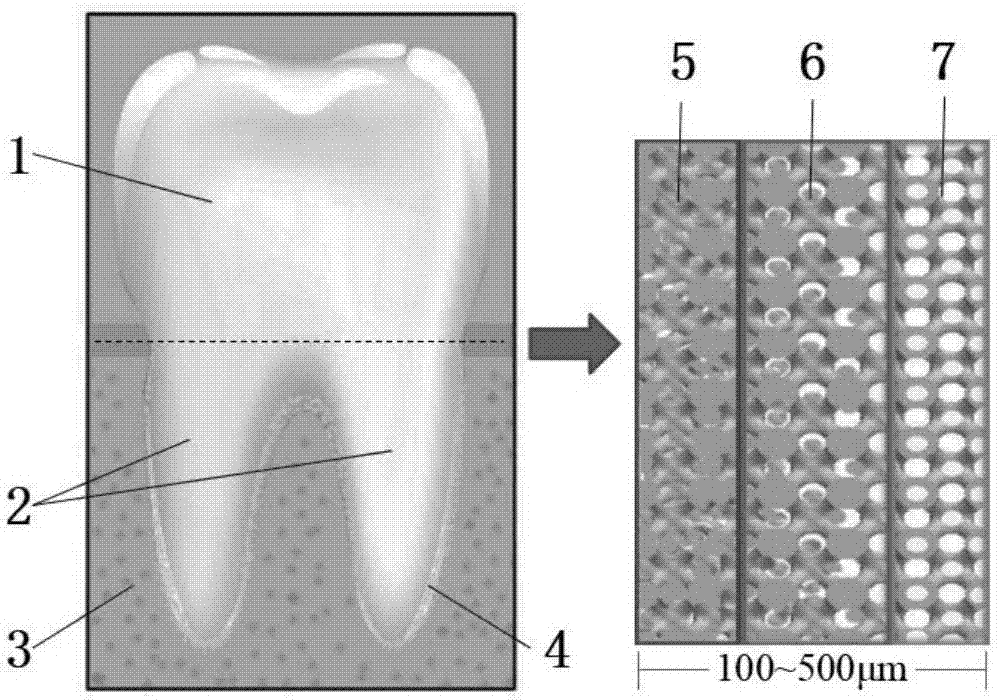

[0072] (1) Combine the medical detection information of CT, X-ray and oral scan to obtain the overall structural information of a single natural tooth-molar, use Mimics and Geomagic software to build a highly simulated molar tooth model, and design the three-dimensional connected gradient of the root surface Porous structure, the layer thickness is 200μm, and the hole shape is round;

[0073](2) Mix zirconium nitrate and sodium hydroxide evenly, slowly add a solution containing Y and Ca doping elements, use the spontaneous heating reaction of sodium hydroxide dissolution, and Zr 4+ , Y 3+ and Ca 2+ Ionic chemical co-precipitation, after separation, drying and heat treatment, obtained Y and Ca elements co-stabilized nano-ZrO 2 Powder.

[0074] (3) the nanometer ZrO that step 2 obtains 2 The powder is mixed with photosensitive resin by ball milling to prepare ceramic-photosensitive resin prefabricated slurry with high solid phase content, in which ZrO 2 The ratio of powder ...

Embodiment 2

[0079] (1) Combine the medical detection information of CT, X-ray and oral scan to obtain the overall structure information of a single natural tooth-incisor, use Mimics and Geomagic software to build a highly simulated incisor tooth model, and design the three-dimensional connected gradient of the root surface Porous structure, the layer thickness is 200μm, and the hole shape is round;

[0080] (2) Mix zirconium nitrate and sodium hydroxide evenly, slowly add a solution containing Y, Ca and Al doping elements, use the spontaneous heating reaction of sodium hydroxide dissolution, and Zr 4+ , Y 3+ , Ca 2+ and Al 3+ Ionic chemical co-precipitation, after separation, drying and heat treatment, get Y, Ca and Al elements co-stabilized nano-ZrO 2 Powder.

[0081] (3) the nanometer ZrO that step 2 obtains 2 The powder is mixed with photosensitive resin by ball milling to prepare ceramic-photosensitive resin prefabricated slurry with high solid phase content, in which ZrO 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com