High-carbon graphitic steel roller ring for profile steel universal mill and manufacturing method of high-carbon graphitic steel roller ring

A universal rolling mill and manufacturing method technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of easy cracking, poor thermal crack resistance, sticking to steel, etc., to reduce the tendency of sticking to steel and less sensitive to thermal effects. , the effect of moderate breaking strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

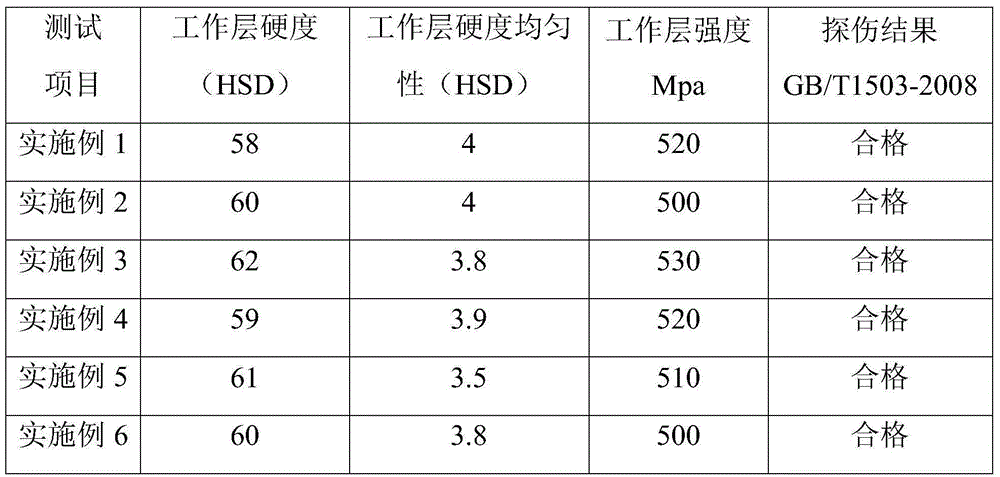

Embodiment 1

[0054] A high-carbon graphite steel roll ring for a steel universal rolling mill, comprising an outer layer of high-carbon graphite steel and a core of low-carbon low-alloy graphite steel, the chemical composition and mass percentage of the outer layer are: C : 2.13%, Si: 1.75%, Mn: 1.00%, P≤0.03%; S≤0.02%, Cr: 1.22%, Ni: 1.00%, Mo: 0.50%, the rest is Fe and unavoidable impurities;

[0055] The chemical components and mass percentages of the core are: C: 1.30%, Si: 1.20%, Mn: 0.70%, P: 0.03%; S: 0.01%, Cr: 0.35%, and the rest are Fe and unavoidable impurities.

[0056] First of all, modeling, the roll body model in the casting mold adopts a metal mold sprayed with paint inside, the roll neck model in the casting mold adopts quartz sand clay modeling, and then uses the following manufacturing method to manufacture high-carbon graphite steel roll rings for steel universal rolling mills :

[0057] A. Intermediate frequency furnace smelting. Raw materials with low P, S and impur...

Embodiment 2

[0067] The preparation process is basically the same as that of Example 1, the difference being that in the step A, the melting temperatures of the outer layer raw material and the core raw material are both 1590°C.

Embodiment 3

[0069] The preparation process is basically the same as that of Example 1, the difference being that in the step B, the addition amounts of Si-Ca grains, FeSiMgRE alloys, 1# alloys and Si-Fe grains are 0.4%, 1.5%, 1.1%, 0.5%, respectively. %; the number of inoculation treatments is 4 times; the particle size of Si-Ca particles and Si-Fe particles are both 12mm; the sedation time of molten steel for inner and outer layers of ladle and molten steel for core material is both 8 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com