Mesh subaqueous patching material of interpenetrating polymer of epoxy/polyurethane, preparing process and application

A technology of interpenetrating polymer and repair material, applied in the field of underwater repair material, which can solve the problems of single use and poor mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

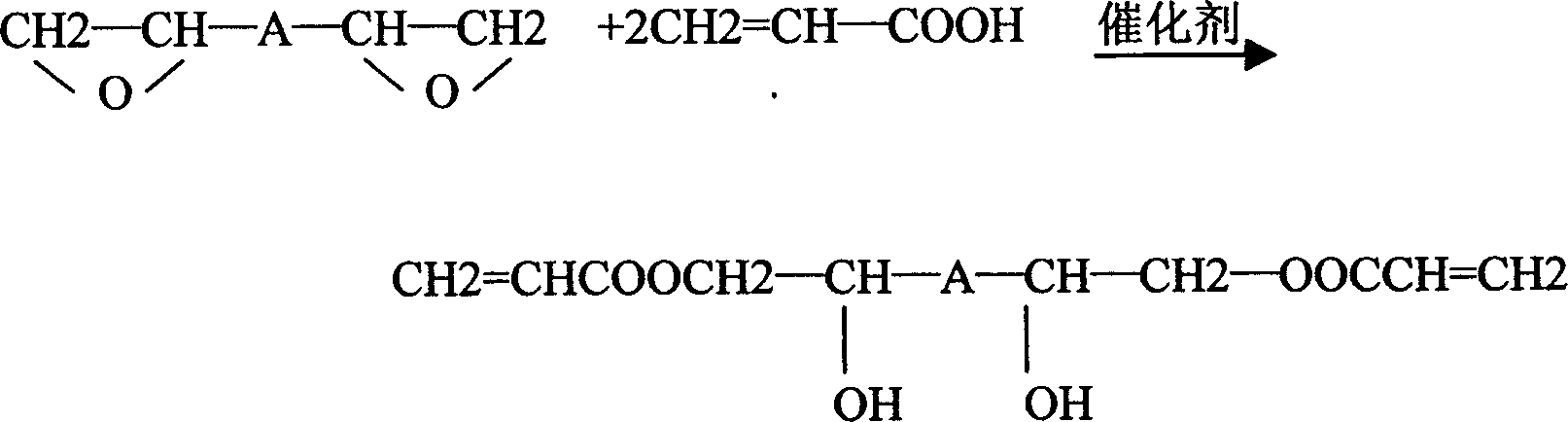

Method used

Image

Examples

Embodiment 1

[0043] Epoxy / polyurethane interpenetrating polymer network underwater repair material, which consists of the following components (amounts are parts by weight): acrylic epoxy resin 100, polyurethane prepolymer (NCO / OH is 2.5) 25, styrene (diluted agent) 50, benzoyl peroxide (initiator) 0.5-1.0, N,N-dimethylaniline (accelerator) 0.1-0.2.

[0044] The preparation method of above-mentioned epoxy / polyurethane interpenetrating polymer network underwater repairing material, it comprises the steps:

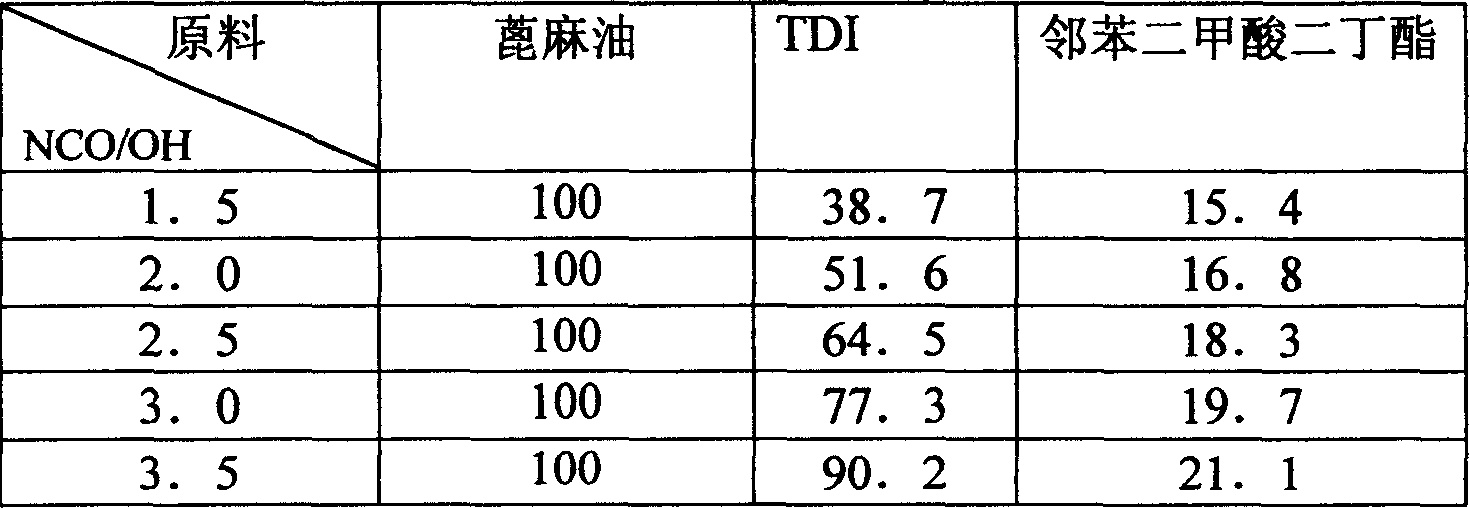

[0045] The synthesis of polyurethane prepolymer, the synthesis of acrylic epoxy resin; the synthetic method of described polyurethane prepolymer is: the castor oil of 90-100 weight part, the dibutyl phthalate of 15-25 weight part are poured into In the reaction body, stir evenly, then add 35-95 parts by weight of toluene diisocyanate, add it while stirring, let it rise to 60°C naturally, then cool down to 20-30°C, then heat slowly, and keep stirring to control the reaction When the temp...

Embodiment 2

[0049] Epoxy / polyurethane interpenetrating polymer network underwater repair material, which consists of the following components (amounts are parts by weight): acrylic epoxy resin 100, polyurethane prepolymer (NCO / OH is 2.5) 25, methacrylic methyl Ester (diluent) 50, benzoyl peroxide (initiator) 0.5-1.0, N,N-dimethylaniline (accelerator) 0.05-0.10, trihexanolamine 0.1 parts by weight.

[0050] The preparation method is the same as in Example 1.

[0051] Reality

[0052] Below is the experiment of investigating the epoxy / polyurethane interpenetrating polymer network underwater repair material of the present invention: the experiment will be 15 * 15 * 15cm 3 The concrete test block is split and put together again, and a grouting nozzle and an exhaust nozzle are pasted at both ends along the diagonal line, and the seam is sealed with epoxy glue, and the sealed concrete test block is filled with water and put into the water for grouting , After the grout pushes the wa...

Embodiment 3

[0054] Epoxy / polyurethane interpenetrating polymer network underwater repair material, which consists of the following components (amounts are parts by weight): acrylic epoxy resin 100, polyurethane prepolymer (NCO / OH is 2.5) 25, styrene (diluted agent) 40, benzoyl peroxide (initiator) 0.5-1.0, N,N-dimethylaniline (accelerator) 0.1-0.2, cement 200, sand 200.

[0055] The preparation method is: after preparing according to Example 1, add 200 parts by weight of cement and 200 parts by weight of sand and mix evenly, and pass the sand through a 0.63mm sieve. It should be noted that the ratio of cement and sand can be appropriately increased or decreased in practical applications. Under the circumstances, the use of the underwater repair material of the present invention is not greatly affected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com