Solid-waste-based low-alkalinity porous ecological pervious concrete and preparation method thereof

A technology of permeable concrete and low alkalinity, used in excavation, ceramic products, cement production, etc., can solve the problems of difficulty in compatibility, inability to meet the requirements of plant root growth, and high alkalinity in the pores of ecological concrete, and achieve cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] The third embodiment of the present invention provides an application of the above-mentioned solid waste-based low-alkalinity porous ecological permeable concrete in slope protection.

[0042] In order to enable those skilled in the art to understand the technical solution of the present invention more clearly, the technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

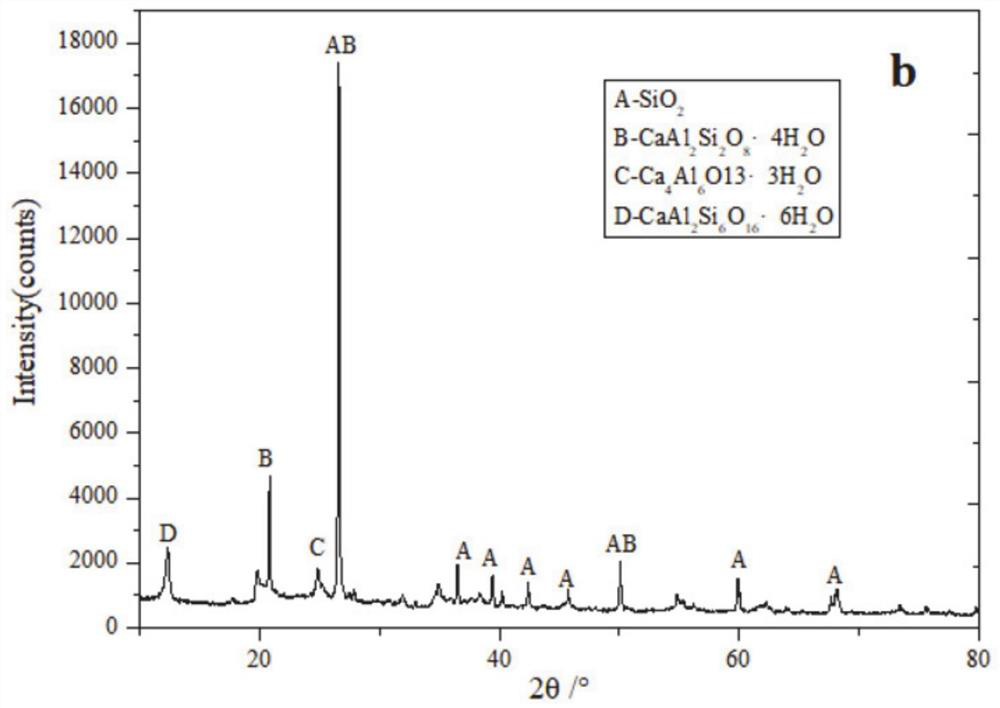

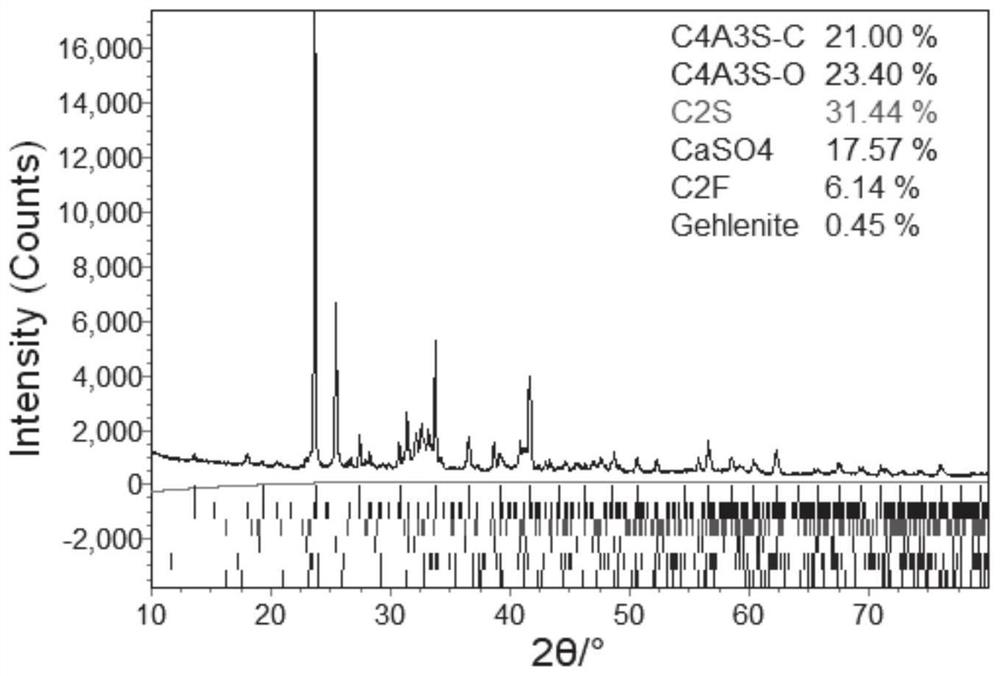

[0043]The solid waste-based sulphoaluminate cementitious materials used in the following examples are mixed evenly in a mass ratio of 38:17:12:33, and the quarry waste rock powder, power plant desulfurization gypsum, steel slag, and aluminum slag from an aluminum plant are mixed evenly in a rotary The intermediate is calcined at 1250°C for 30 minutes in a kiln, mixed and ground with 2% limestone powder and 6% gypsum. The characterization of the prepared solid waste-based sulfoaluminate gelling material is as follows: Figure 3-4 shown.

...

Embodiment 1

[0049] A solid waste-based low-alkalinity porous ecological concrete consists of the following components by weight: 13.82 parts of low-alkalinity gelling material, 82.95 parts of excavation gangue aggregate, 0.14 part of adhesive, 0.03 part of water reducing agent, and 3.1 parts of water. The binder is dispersible latex powder, and the water reducer is polycarboxylate water reducer.

[0050] The low-alkalinity cementitious material is made by mixing 85 parts of solid waste-based sulfoaluminate cementitious material, 12 parts of a mixture of red gangue and waste rock powder, and 3 parts of desulfurized gypsum.

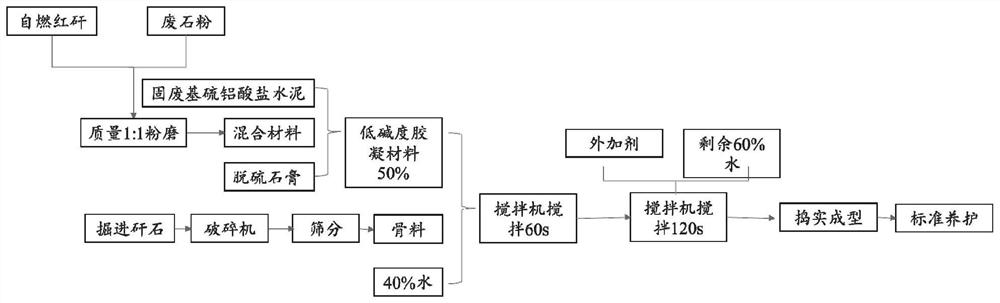

[0051] Such as figure 1 As shown, the aggregates are graded as 5-10mm particle size, 2.5-5mm excavation gangue mass ratio of 3:1 excavation gangue aggregate, 50% low-alkalinity cementitious material prepared, and 40% water demand Put the water in the mixer according to the proportion and stir it for 50s, then add the remaining 50% of the cementitious material, binder,...

Embodiment 2

[0054] A solid waste-based low-alkalinity porous ecological concrete consists of the following components by weight: 16.04 parts of low-alkalinity cementitious material, 80.26 parts of excavation gangue aggregate, 0.15 part of adhesive, 0.04 part of water reducing agent and 3.1 parts of water. The binder is dispersible latex powder, and the water reducer is polycarboxylate water reducer.

[0055] The low-alkalinity cementitious material is made by mixing 80 parts of solid waste-based sulfoaluminate cementitious material, 15 parts of a mixture of red gangue and waste rock powder, and 5 parts of desulfurized gypsum.

[0056] Such as figure 1 As shown, the aggregate is graded as a particle size of 5-10mm, 2.5-5mm excavation gangue mass ratio of 4:1 excavation gangue aggregate, 50% of the prepared low-alkalinity cementitious material, and 40% of water demand Put the water in the mixer according to the proportion and stir it for 50s, then add the remaining 50% of the cementitious ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com