A kind of preparation method of rust stone sand

A technology of stone sand and pebbles, applied in the field of preparation of rust stone sand, can solve the problems of single effect, the effect of the product cannot reach the effect of real stone, etc., and achieve the effects of reasonable ratio, low production cost and difficult diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

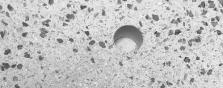

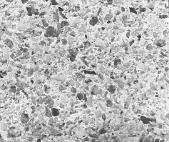

Image

Examples

Embodiment 1

[0029] A preparation method of rust stone sand, comprising the following steps:

[0030] (1) Weigh 20 parts of black stones, the particle size of which is between 3-5mm; add 0.9 parts of water and mix well to obtain premixed stones.

[0031] (2) Weigh 0.94 parts of iron oxide yellow powder, 0.02 part of iron oxide red powder, 0.009 part of iron oxide black powder, 0.074 part of polymer concentrated glue powder, and 1 part of 525 white cement;

[0032] Mix iron oxide yellow powder, iron oxide red powder, iron oxide black powder, polymer concentrated glue powder, and 525 white cement and stir evenly to obtain a mixture.

[0033] (3) Add the mixture into the premixed stone and stir for 30 minutes to obtain the total mixture.

[0034] (4) Take out the well-mixed total mixture, put it into an oven, heat up to 88°C at a speed of 3°C / min, bake for 2.5 hours, then take it out, and leave it in the air for 5 hours to obtain a ruststone sand body; 10 After an hour, crush the hardened r...

Embodiment 2

[0038] A preparation method of rust stone sand, comprising the following steps:

[0039] (1) Weigh 20 parts of black stones, the particle size of which is between 3-5 mm; add 1.1 parts of water and mix well to obtain premixed stones.

[0040] (2) Weigh 0.98 part of iron oxide yellow powder, 0.019 part of iron oxide red powder, 0.009 part of iron oxide black powder, 0.078 part of polymer concentrated glue powder, and 1.1 part of 525 white cement;

[0041] Mix iron oxide yellow powder, iron oxide red powder, iron oxide black powder, polymer concentrated glue powder, and 525 white cement and stir evenly to obtain a mixture.

[0042] (3) Add the mixture into the premixed stone and stir for 40 minutes to obtain the total mixture.

[0043] (4) Take out the well-mixed total mixture, put it into an oven, heat up to 90° C. at a rate of 4° C. / min, bake for 2 hours, then take it out, and leave it in the air for 5 hours to obtain a rusty stone sand body; 10 After an hour, crush the hard...

Embodiment 3

[0047] A preparation method of rust stone sand, comprising the following steps:

[0048] (1) Weigh 22 parts of black stones, the particle size of which is between 3-5mm; add 1.2 parts of water and mix well to obtain premixed stones.

[0049] (2) Weigh 0.94 parts of iron oxide yellow powder, 0.02 part of iron oxide red powder, 0.009 part of iron oxide black powder, 0.074 part of polymer concentrated glue powder, and 1 part of 525 white cement;

[0050] Mix iron oxide yellow powder, iron oxide red powder, iron oxide black powder, polymer concentrated glue powder, and 525 white cement and stir evenly to obtain a mixture.

[0051] (3) Add the mixture into the premixed stone and stir for 40 minutes to obtain the total mixture.

[0052] (4) Take out the well-mixed total mixture, put it into an oven, heat up to 82°C at a rate of 3°C / min, bake for 3.5 hours, then take it out, and leave it in the air for 6 hours to obtain the rust stone sand body; 10 After an hour, crush the hardened...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com