Anti-freezing anti-seepage anti-cracking concrete and preparation method thereof

A concrete and mixture technology, applied in the field of concrete, can solve the problems of low crack resistance, frost resistance and impermeability, etc., and achieve the effects of increasing the hydration reaction rate, increasing the specific surface area, and improving the frost resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

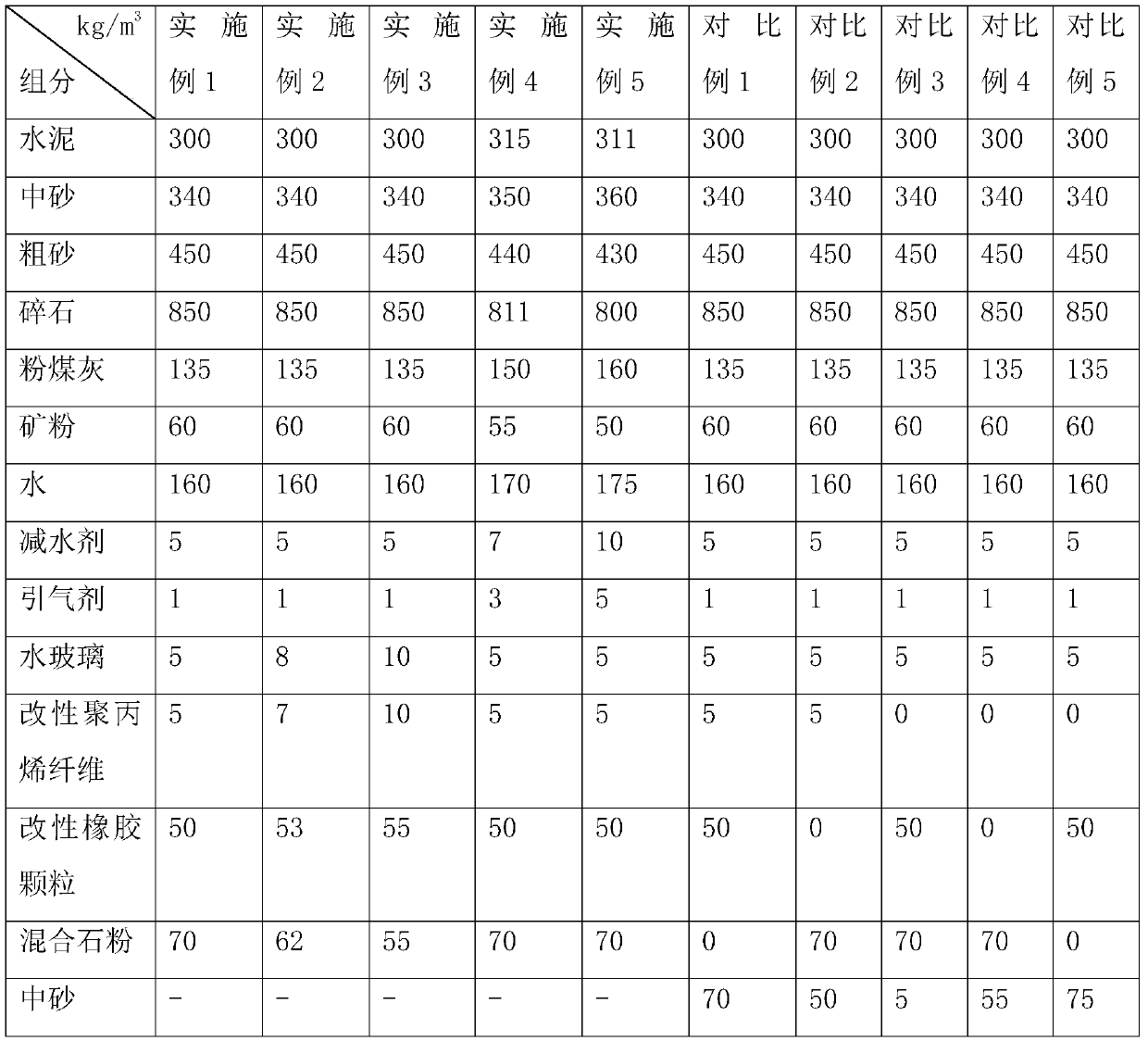

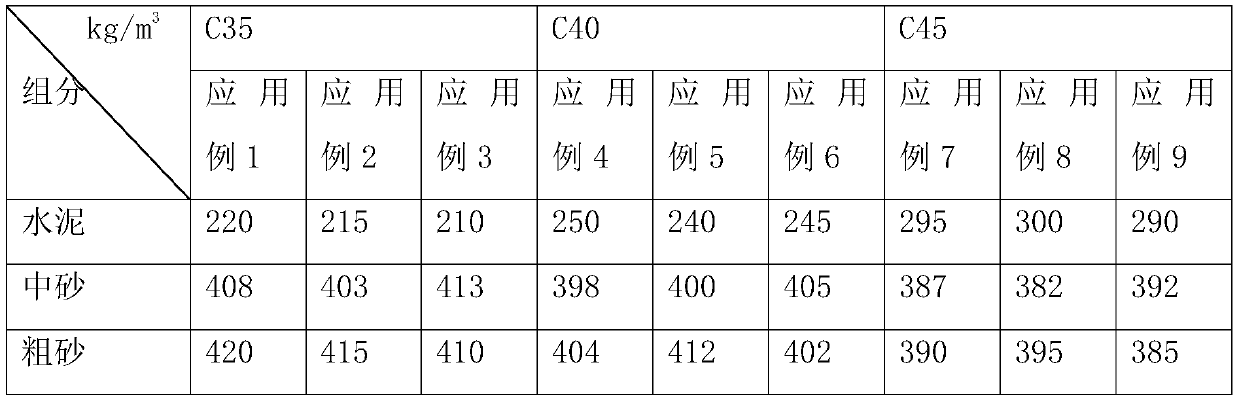

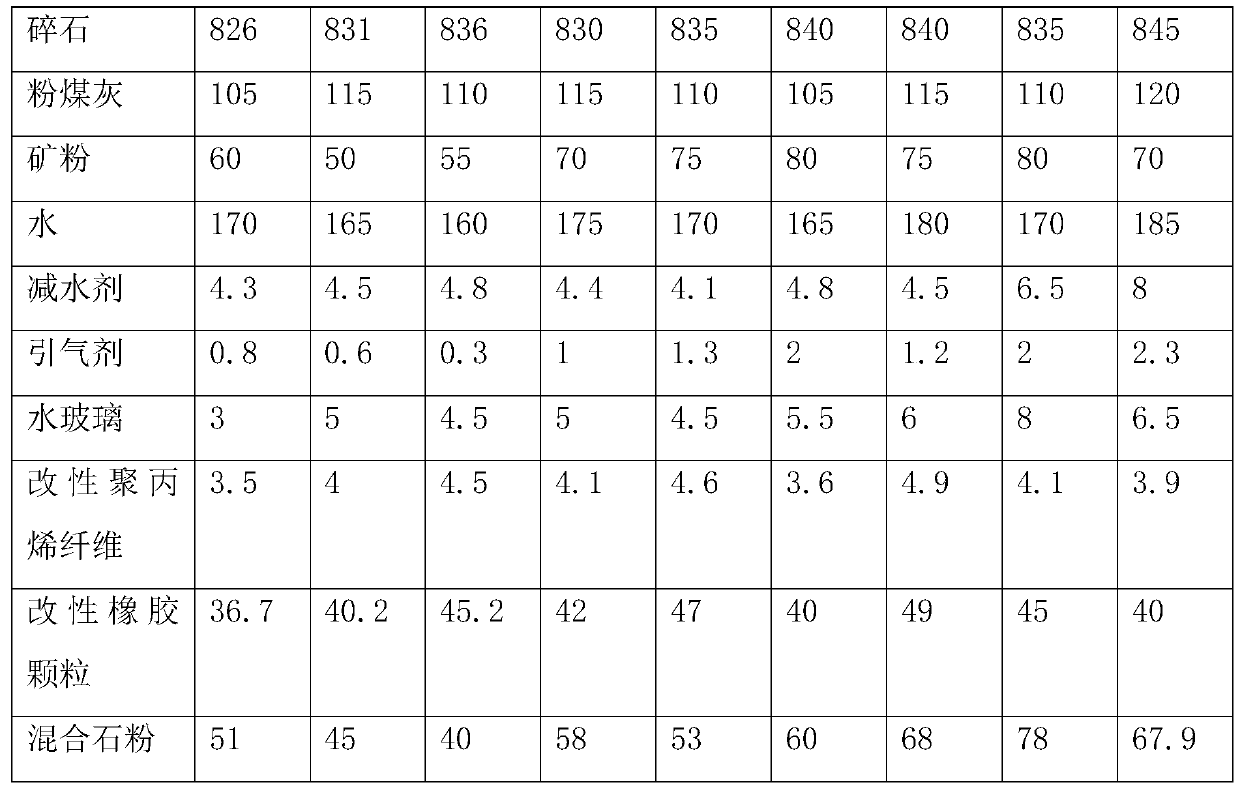

Method used

Image

Examples

preparation example 1-3

[0040] In the preparation example 1-3, nano-silica is selected from the nano-silica sold by Nanjing Baokete New Material Co., Ltd. with the article number IC010, and vinyltrimethoxysilane is selected from the article number sold by Nanjing Ron Silicon Material Co., Ltd. The vinyltrimethoxysilane and sodium dodecylbenzenesulfonate of KH-171 are selected from the sodium dodecylbenzenesulfonate sold by Guangzhou Zhixin Trading Co., Ltd. with the item number P-70.

preparation example 1

[0041] Preparation example 1: (1) 1 kg of rubber particles with a particle size of 250 μm was placed in 3 kg of a sodium hypochlorite solution with a mass concentration of 8%, soaked for 30 minutes, washed with water until neutral, and dried under an infrared lamp;

[0042] (2) 5kg nano silicon dioxide is dispersed in 20kg water, add the rubber particle that 0.6kg vinyltrimethoxysilane, 0.1kg sodium dodecylbenzene sulfonate and step (1) make, after stirring, in Drying at room temperature until the moisture content is lower than 5%, the modified rubber particles are obtained.

preparation example 2

[0043] Preparation example 2: (1) 2 kg of rubber particles with a particle size of 450 μm were placed in 6 kg of a sodium hypochlorite solution with a mass concentration of 9%, soaked for 45 minutes, washed with water until neutral, and dried under an infrared lamp;

[0044] (2) 8kg nano silicon dioxide is dispersed in 25kg water, add the rubber particle that 0.7kg vinyltrimethoxysilane, 0.2kg sodium dodecylbenzene sulfonate and step (1) make, after stirring, in Drying at room temperature until the moisture content is lower than 5%, the modified rubber particles are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com