Preparation method of microcrystalline glass

A technology of glass-ceramics and particles, which is applied in the field of glass-ceramics preparation, can solve the problems of heat resistance and toughness to be improved, glass-ceramic wear resistance and poor mechanical properties, etc., so as to improve mechanical properties and improve bonding The effect of strength, thermal stability and mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

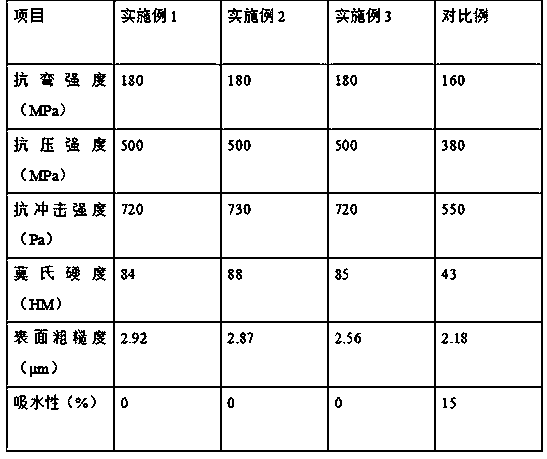

Examples

preparation example Construction

[0031] A method for preparing glass ceramics, comprising the steps of:

[0032] (1) Take the straw, crush it through a 120-mesh sieve, take the sieved particles and lay them on the container with a thickness of 2~4cm, and lay quicklime on the particles, control the thickness of the quicklime to be 0.1~0.3cm, and then alternately use the same thickness Lay sieved particles and quicklime to 30~45% of the height of the container, add 45~60% of the container volume of water, mix, let stand for 20~24h, add 4~8% of the container volume of the mixture, seal the container, and put it under room temperature Stand still for 4-8 days, filter with suction, collect the filter residue, rinse with deionized water until the lotion is neutral, then move to a drying oven at 65-80°C and dry until the water content is below 1%, to obtain pretreated straw particles;

[0033] (2) According to the number of parts by mass, take 20~40 parts of pretreated straw particles, mix 25~35 parts of oxidant, st...

Embodiment 1

[0038] Straw: Cotton straw.

[0039] Mixing material: take biogas slurry according to the mass ratio of 4:1, and mix watermelon seeds crushed through a 100-mesh sieve to obtain the mixing material.

[0040] Coating solution: Mix potassium permanganate, sodium alginate, xanthan gum, and water at a mass ratio of 2:4:0.2:10 to obtain a coating solution.

[0041] Mixed stone: In parts by weight, 10 parts of sepiolite, 40 parts of bauxite and 3 parts of copper alloy powder are mixed to obtain the mixed stone.

[0042] Oxidant: Mix potassium permanganate, sodium periodate, and water in a mass ratio of 4:2:12 to obtain the oxidant.

[0043] Adjuvant: mix sodium fluoride, nano-iron powder, and sodium chloride at a mass ratio of 4:1:0.2 to obtain the adjuvant.

[0044] Waste residue pretreatment: soak glass slag and carbide slag in a sodium citrate solution with a concentration of 0.1mol / L for 3 hours at a mass ratio of 1:1:10, filter, and dry the filter residue to obtain waste resid...

Embodiment 2

[0052] Straw: wheat straw.

[0053] Mixing material: take biogas slurry according to the mass ratio of 5:1, and mix watermelon seeds crushed through a 100-mesh sieve to obtain the mixing material.

[0054] Coating solution: Mix potassium permanganate, sodium alginate, xanthan gum, and water at a mass ratio of 2:6:0.2:10 to obtain a coating solution.

[0055] Mixed stone material: in parts by weight, 15 parts of sepiolite, 50 parts of bauxite and 4 parts of copper alloy powder are mixed to obtain the mixed stone material.

[0056] Oxidant: Mix potassium permanganate, sodium periodate and water at a mass ratio of 4:2.5:15 to obtain the oxidant.

[0057] Adjuvant: mix sodium fluoride, nanometer iron powder, and sodium chloride at a mass ratio of 6:1:0.2 to obtain the adjuvant.

[0058] Waste residue pretreatment: soak glass slag and carbide slag in a sodium citrate solution with a concentration of 0.1mol / L for 5 hours at a mass ratio of 1:2:10, filter, and dry the filter residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com