Carrier pile machine compaction karst cave filler and karst cave filling method

A filling method and filling technology, which are used in filling, construction, infrastructure engineering, etc., can solve the problems of insufficient filling quality, no open karst caves, low efficiency, etc., and ensure the quality of piles and the simplicity of raw materials. high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of filler for cave filling, the filler is a mixture of gravel, sandstone, backfill clay, cement and fly ash at a ratio of 1:1:3:0.2:0.2, and the content of the soil and stone The amount of water is kept at 15-25%.

[0025] The packing also includes pre-packed flakes.

[0026] The raw materials used are crushed stone, sand, backfill clay, cement and fly ash, which are relatively easy to obtain. The crushed stone and sand are granular, and the filler is fully mixed with powdered backfill clay, cement and fly ash. , has good support, and can fill the gap after pre-filling the rubble, and has good filling performance at the same time.

Embodiment 2

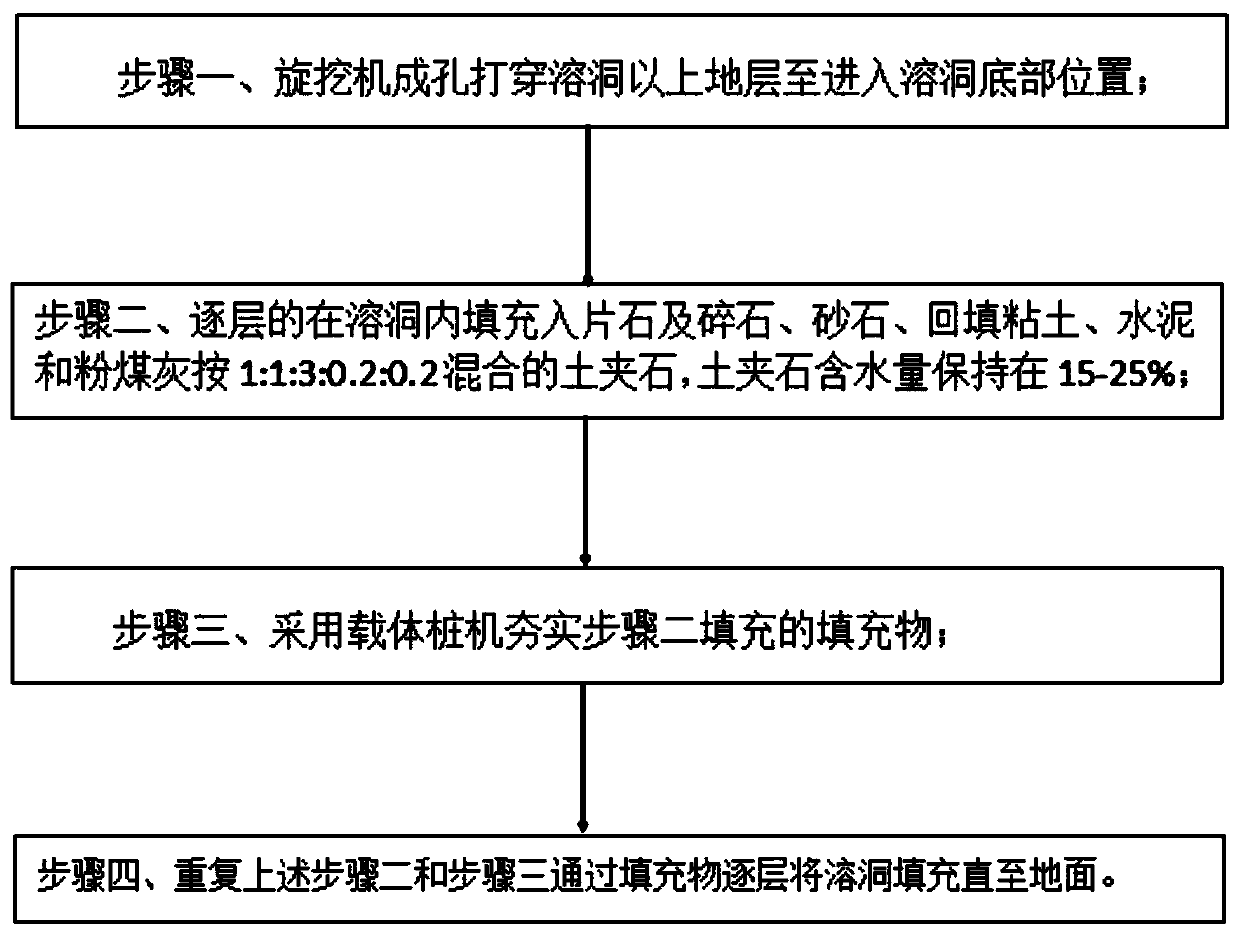

[0028] A method for filling karst caves perforated by a rotary excavator, comprising the following steps:

[0029] Step 1. The rotary excavator drills the hole above the karst cave to the bottom of the karst cave;

[0030] Step 2: Fill the cave layer by layer with flakes, crushed stones, sandstone, backfill clay, cement and fly ash according to the ratio of 1:1:3:0.2:0.2. 15-25%;

[0031] Step 3, using a carrier pile driver to tamp the filler filled in step 2;

[0032] Step 4: Repeat the above step 2 and step 3 to fill the cave layer by layer with filler until it reaches the ground.

[0033] The filling in the cave is filled to a height of 100-150cm per layer, and then filled layer by layer after being compacted and flattened.

[0034] The filling order of the filler is as follows: firstly put in the flakes, and then put in the gravel, sand, backfill clay, cement and fly ash mixed in the ratio of 1:1:3:0.2:0.2.

[0035] Before the rotary excavator is drilled and filled, in...

specific Embodiment approach

[0037] Before construction, investigate the conditions of the caves in the construction area, analyze the size, depth and volume of the caves, and prepare sufficient filling materials in advance;

[0038] That is, the amount of filling required for cave filling is determined by the cave space, and the relevant parameters are pre-calculated and prepared;

[0039] The rotary excavator drills through the formation above the karst cave to the bottom of the karst cave. The drilling of the rotary excavator refers to the operation method of the rotary excavator;

[0040] Then fill the cave layer by layer with flakes, crushed stones, sandstone, backfill clay, cement and fly ash at a ratio of 1:1:3:0.2:0.2. The water content of the soil and stones is kept at 15- 25%;

[0041] The filling order of the filler is as follows: firstly put in the flakes, then put in gravel, sand and gravel, backfill clay, cement and fly ash mixed in 1:1:3:0.2:0.2;

[0042] Use a carrier pile machine to tam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com