Pavement crack disposal structure and technology

A pavement crack and structure technology, applied to roads, roads, pavement details, etc., can solve the problems of blocking the mutual bonding between asphalt and aggregate, reducing the bearing capacity of pavement structure, and endangering road performance, so as to improve the performance, The effect of reducing traffic noise and standardizing the structural design of asphalt pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First, adjust the width of the slotting machine tool according to the designed crack slotting width, and debug the equipment to ensure that the equipment works normally; secondly, pre-run the equipment before starting slotting; finally, slot along the crack, according to the designed slotting Groove depth, adjust the depth adjuster to reach the designed depth. When grooving, ensure that the centerline of the grooving is consistent with the centerline of the crack. Whether the crack has been grooved or not, there will be more or less water, dust, debris and sundries in the crack. Ensure that the sealing material has good adhesion to the wall of the crack (or groove), and the wall of the crack (or groove) should be thoroughly cleaned and completely dry. The seam cleaning method generally uses compressed air blowing, sandblasting, wire brushing, and high-pressure water spraying. Opening a groove along the crack is mainly to provide a sufficient space for the crack that is...

Embodiment 2

[0024] According to the method of Example 1, the pavement crack treatment process of the present invention is applied to a certain expressway K636+785-K637+885. The test section is about 8m long, and grooves are made at 0.4cm on both sides of the crack, and then filled with high-permeability Epoxy resin material, after fine milling, add 2.5cm thick U-Pave10 asphalt mixture to complete the repair.

Embodiment 3

[0026] According to the method of Example 1, the pavement crack treatment process of the present invention is applied to a certain expressway K636+785~K637+885. The test section is about 10m long, and grooves are made at 0.5cm on both sides of the crack, and then filled with high-permeability Epoxy resin material, after fine milling, add 2.5cm thick U-Pave10 asphalt mixture to complete the repair.

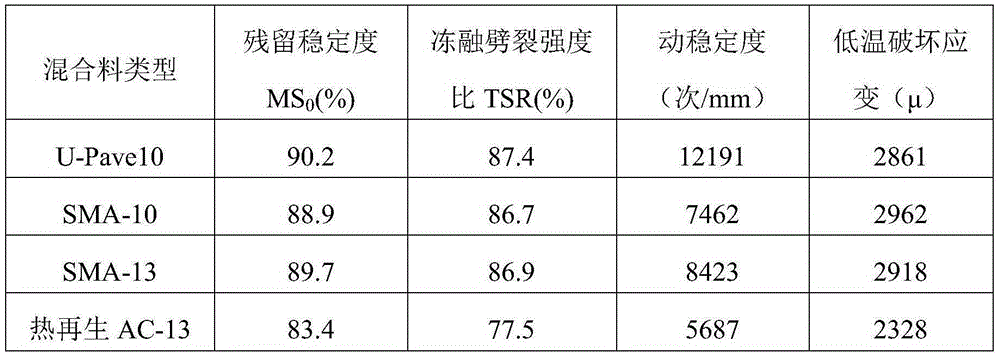

[0027] Various performance indicators of different mixture types

[0028]

[0029]Through the comparison and analysis of previous data, it is found that the high temperature resistance of U-Pave10 asphalt mixture is particularly outstanding, and the water damage resistance and low temperature crack resistance are basically equivalent to SMA. After U-Pave adopts integrated paving construction, the lower layer on the pavement forms a whole, and the anti-fatigue performance is significantly enhanced. Tracking and monitoring data from the test road show that the construction depth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com