Ultrathin asphalt mixed material and preparation method thereof

A technology of asphalt mixture and mixture, which is applied in the field of asphalt mixture, can solve the problems of overlaying too thick asphalt mixture, improve driving comfort and safety, reduce road noise, and improve high temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods that do not indicate specific conditions in the following examples, select according to conventional methods and conditions, or according to the following technical performance indicators.

[0022] An ultra-thin asphalt mixture, the mixture formula includes the following components in parts by mass: 10-50 parts of aggregate 5-10mm, 20-50 parts of aggregate 3-5mm, 15-35 parts of aggregate 0-3mm 4-10 parts of mineral powder, 5-8 parts of modified asphalt, 0.2-0.5 parts of special additive for ultra-thin asphalt mixture and 0.2-0.4 parts of polyester fiber.

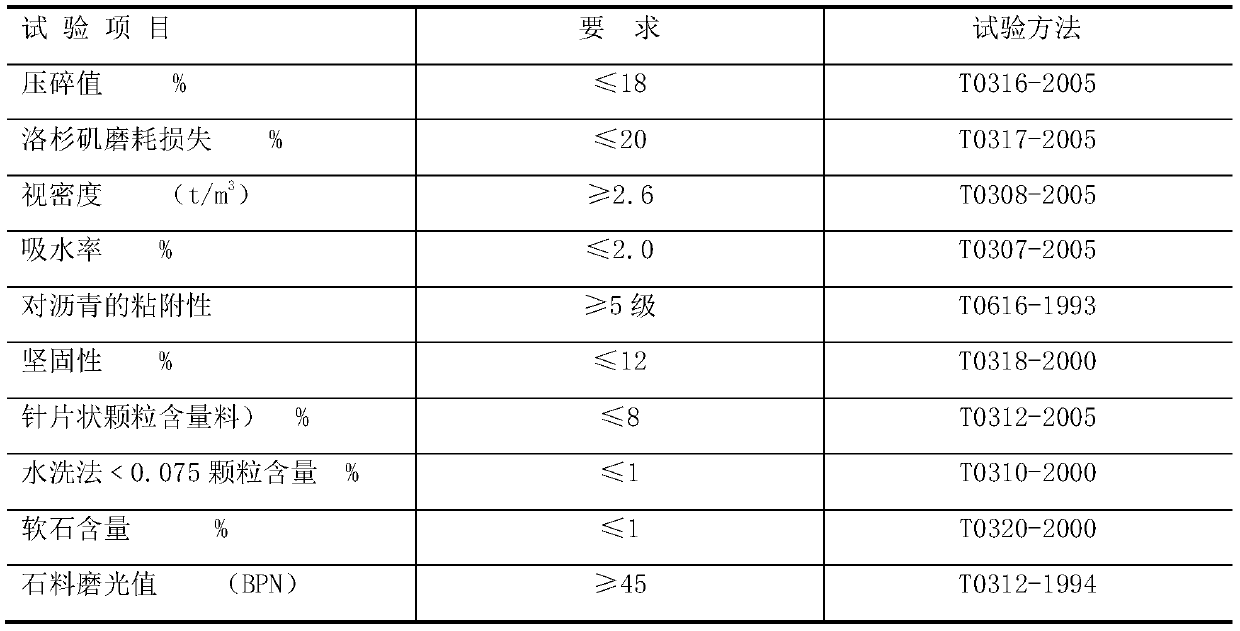

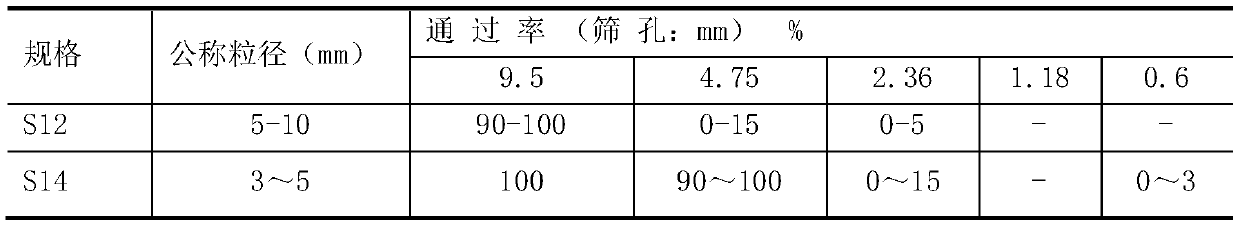

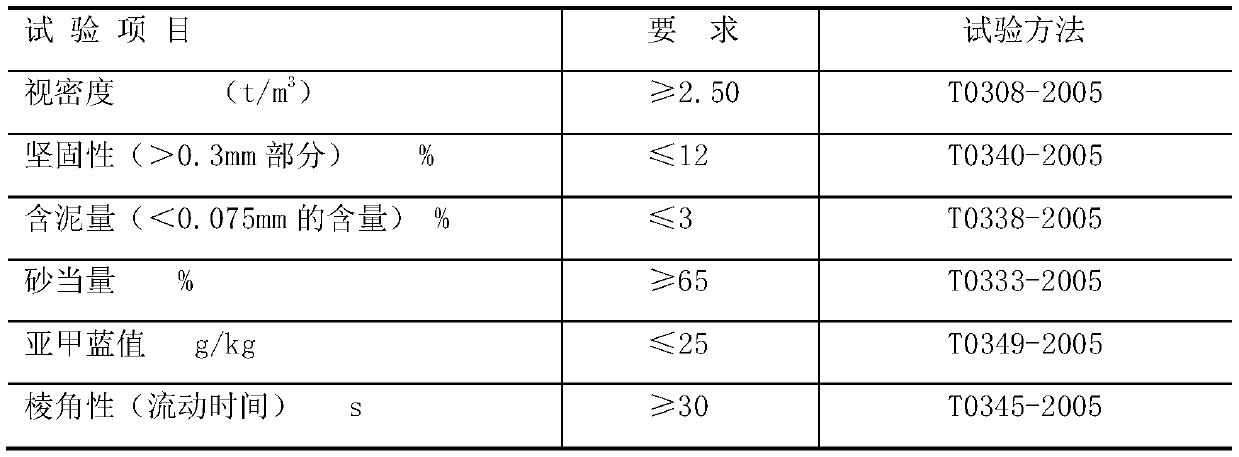

[0023] The 5-10mm aggregate and the 3-5mm aggregate use basalt or diabase, and steel slag can also be used, which must meet the following technical requirements:

[0024] Coarse aggregate (5-10mm, 3-5mm) technical performance indicators

[0025] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com