Mechanical construction method of steel deck ERS system

A construction method and steel bridge deck technology, applied to bridges, bridge parts, bridge construction, etc., can solve problems such as difficulty in ensuring uniformity, unreliable construction quality, time-consuming and labor-intensive efficiency, etc., and achieve the improvement of construction quality and efficiency. The effect of improving construction quality and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

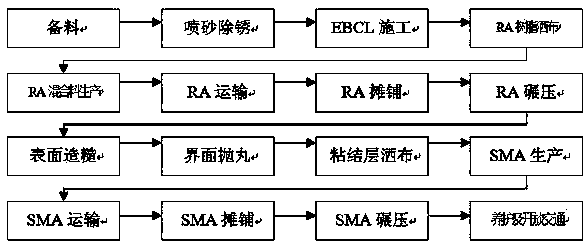

[0013] Such as figure 1 Shown, a kind of steel deck ERS system mechanized construction method of the present invention, the method is:

[0014] 1. Prepare materials

[0015] The construction processes need to be closely connected to ensure the quality of pavement construction. Before construction, it is necessary to prepare the necessary materials and equipment for each construction process, formulate a detailed construction plan, and ensure the smoothness of a single process to ensure the continuity of the entire construction process.

[0016] 2. Sand blasting and rust removal

[0017] A mobile automatic vacuum dust-free sanding machine with a dust suction device is used to completely remove surface corrosion, dust, water stains, etc. on the bridge deck. Each sandblasting part overlaps each other by 3-5cm. Detect the cleanliness and roughness of the steel plate surface after blasting and derusting.

[0018] 3. EBCL construction

[0019] EBCL rubber is composed of two com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com