Composite pavement structure of steel bridge deck and paving method of composite pavement structure

A pavement and steel bridge technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of poor slip resistance of epoxy asphalt concrete, long maintenance time, shortened maintenance time, etc., and achieve low maintenance costs and durability The effect of high and low cost

Inactive Publication Date: 2014-02-19

JIANGYIN BRIDGE BEIJING ENG +3

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] A technical problem to be solved by the present invention is to overcome the defects that the existing steel bridge deck pavement material adopts epoxy asphalt concrete with poor skid resistance, high price and difficult maintenance, while adopting other SMA asphalt concrete is easy to be damaged, and proposes a A composite pavement structure of a steel bridge deck and a pavement method thereof, the composite pavement structure is easy to maintain, and has the good

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Login to View More

Abstract

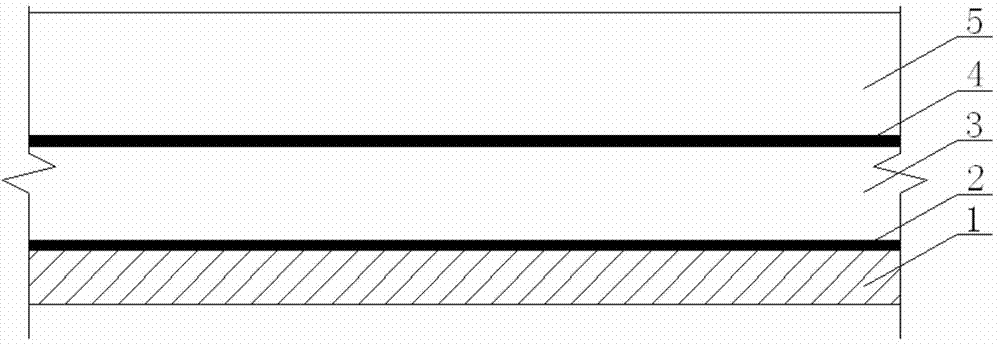

The invention discloses a composite pavement structure of a steel bridge deck. The composite pavement structure comprises a bottom waterproof bonding layer, a lower paving layer, a top bonding layer and a top paving layer. The bottom waterproof bonding layer, the lower paving layer, the top bonding layer and the top paving layer are sequentially paved on the steel bridge deck. The lower paving layer is made of epoxy asphalt concrete, and the top paving layer is made of asphalt concrete. The composite pavement structure has the advantages of both asphalt concrete and stone mastic asphalt (SMA) concrete, construction cost can be reduced, service life can be prolonged, and maintenance period can be shortened.

Description

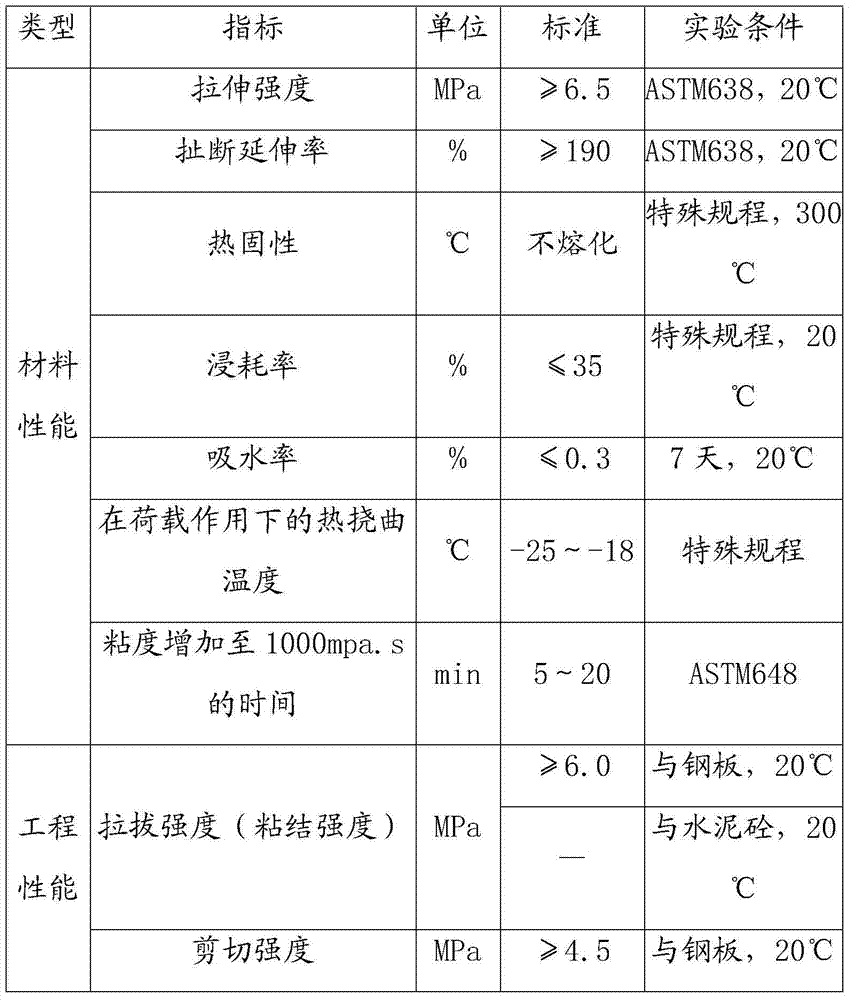

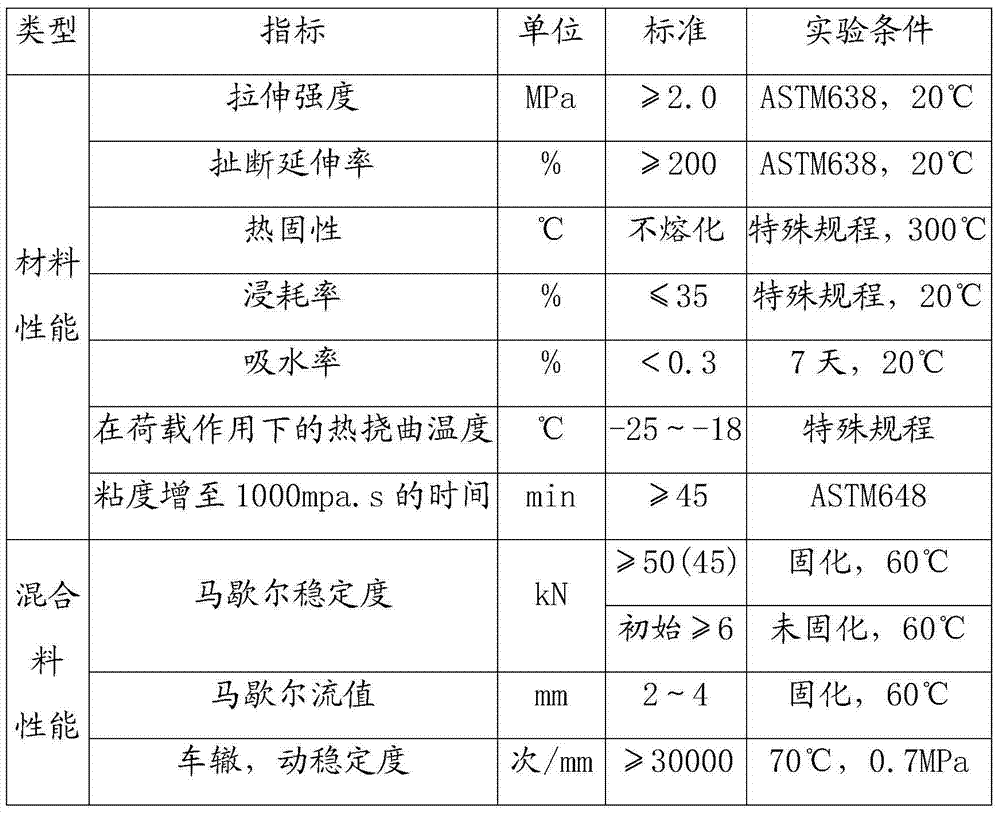

technical field [0001] The invention relates to the field of bridge deck pavement, in particular to a composite pavement structure of a steel bridge deck and a pavement method thereof. Background technique [0002] In recent years, my country's bridge industry has developed rapidly, and more and more long-span steel bridges have been built. As an important part of the bridge structure system, the bridge deck pavement plays an extremely important role in the durability and safety of the bridge. However, at present, there is still no perfect and mature technical solution in the technical field of steel bridge deck pavement in our country. [0003] At present, the pavement materials used for steel bridge decks in my country are mainly epoxy asphalt concrete or SMA asphalt concrete (asphalt mastic macadam mixture). Due to its high strength, epoxy asphalt concrete can thin the pavement layer and reduce its own weight. At the same time, it has excellent durability, chemical corr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01D19/12E01D21/00E01D101/30

Inventor 任伟钱振东秦大航许志宏徐君任自放刘道辉

Owner JIANGYIN BRIDGE BEIJING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com