Mixing and stirring method and device in construction of SBS modified stone mastic asphalt

A technology of modified asphalt and mastic, used in roads, road repair, roads, etc., can solve problems such as reducing production efficiency, increasing construction costs, reducing the overall performance of SBS modified asphalt mastic crushed stone, etc., to achieve productivity Improve and improve the effect of measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

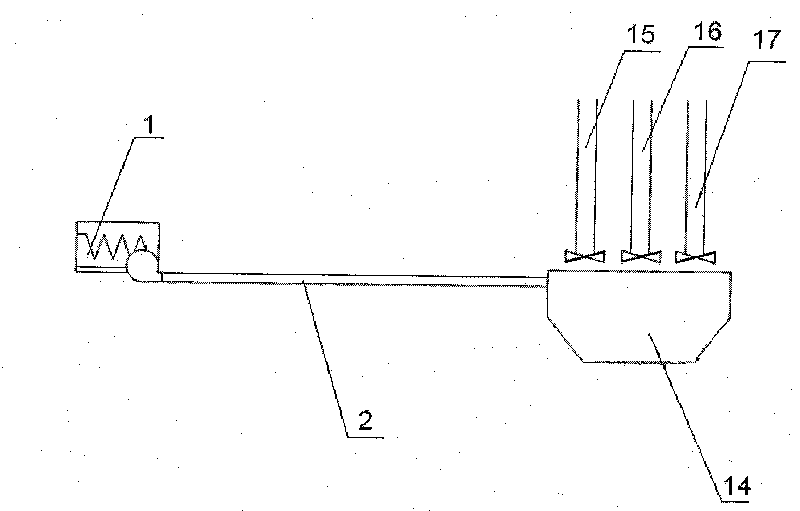

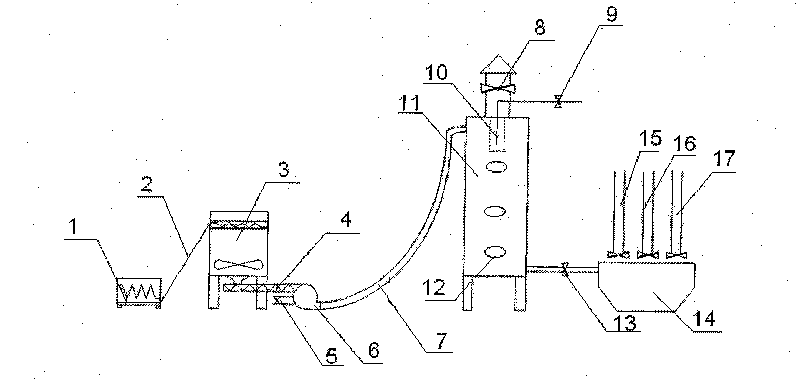

[0016] Embodiment 1, in the mixing equipment, the crusher 1 and the weighing bucket 3 are connected by a conveyor belt 2, the screw conveyor 4 is connected below the weighing bucket 3, the other end of the screw conveyor is connected with the blower 6, and the rear end of the blower 6 is There is an air intake valve 5, and the front end of the blower 6 is connected to the metering storage tank 11 through the pipeline 7, and an exhaust tube is fixed above the metering storage tank 11. There is an exhaust valve 8 in the exhaust tube, and the exhaust is controlled by the exhaust valve 8. There is a cloth bag 10 between the exhaust cylinder and the metering storage cylinder 11 to prevent the lignin fiber from flying out of the exhaust cylinder during the exhaust process. The upper part of the metering storage cylinder 11 is also fixed with a blowback valve 9. It is connected with the mixing cylinder 14, and the discharge is controlled by the discharge valve 13 between the metering ...

Embodiment 2

[0018] Example 2, such as image 3 , Figure 4 As shown, by adding a lignin fiber storage cylinder on the mixing tank, the addition of lignin fiber is parallel to the coarse aggregate discharge time (3-5) seconds of the asphalt mixer (floor), and the aggregate metering, The discharge time is weighed and measured at the same time and on standby, and the above process is circulated. The time of intermittent weighing and measuring of lignin fiber is digested in dry mixing and wet mixing. The feeding time is shortened to 3 to 5 seconds through weighing and measuring. The entire mixing cycle of the material is shortened to 60 seconds, and the productivity of the asphalt mixing machine (building) is increased by 25%. At the same time, the metering accuracy is improved by overcoming the timed volumetric metering of the material (the problem of only paying attention to the feeding time regardless of the actual amount of feeding).

Embodiment 3

[0019] Embodiment 3, self-made crusher, conveyor belt conveyor, metering storage barrel, all the other are purchase items (intake valve, exhaust valve, what discharge valve purchases are French VIM, and metering bucket, screw conveyor, blower are German Benning Hoff). Redesign the control program of lignin fiber addition and weighing measurement in the mixing building, design the setting items and command items, redesign the control circuit, send out signals, respectively control the intake valve, exhaust valve, blowback valve, and discharge valve, and make full use of Weighing and metering improve production efficiency and eliminate measurement errors. The metering storage tank is 1.7 meters high and 0.8 meters in diameter; it is equipped with three material level monitoring points and a back-flushing cleaning system.

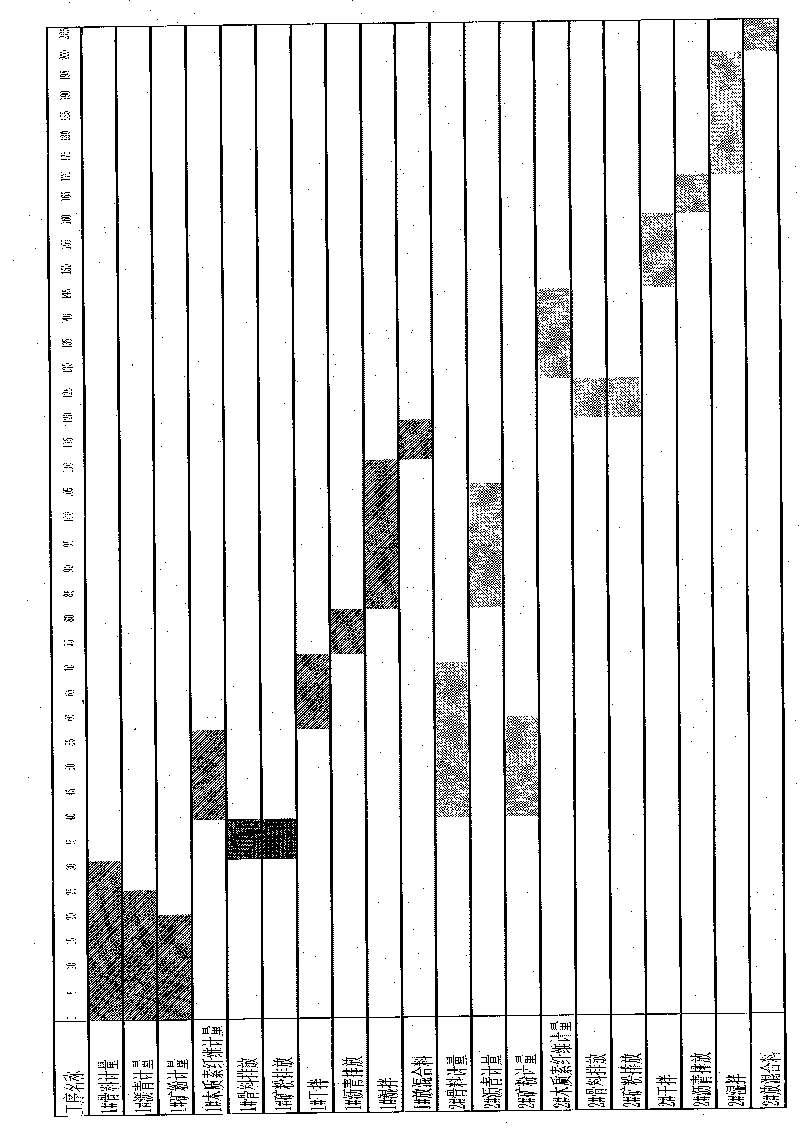

[0020] work status control table

[0021]

[0022] This mixing method adopted in the construction of SBS modified asphalt mastic macadam, it increases the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com