Construction method of expressway stone mastic asphalt (SMA) road surface

A technology of expressway and construction method, applied in the direction of roads, roads, road repair, etc., can solve the problems of high construction technology requirements, spalling, subsidence, etc., and achieve the effect of reducing the probability of cracking and reducing the depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0027] The present invention provides a kind of construction method of expressway SMA pavement, expressway is divided into several sections and is laid, and each section of laying comprises the following steps:

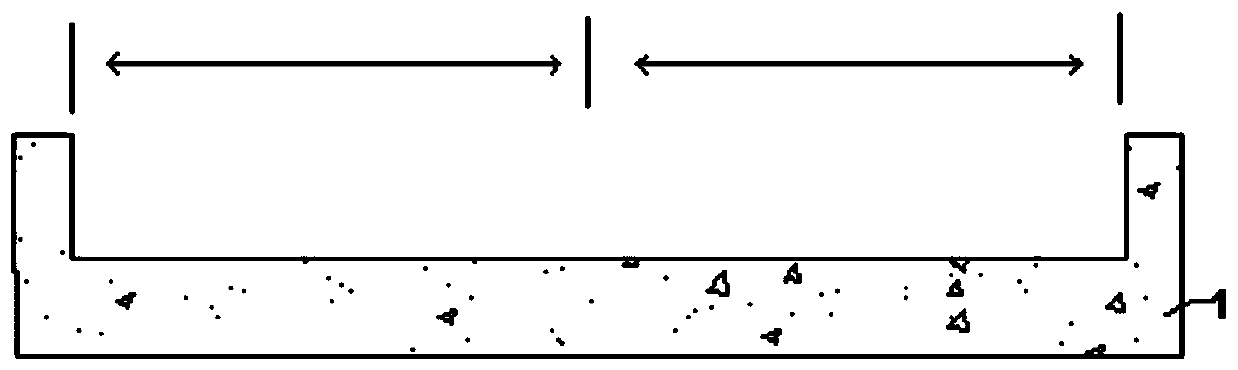

[0028] S1, roadbed 1 treatment: pave the roadbed 1, roll it with a heavy-duty road roller, measure the roadbed 1 with a three-meter ruler, and control the flatness of the roadbed 1 to be 8mm;

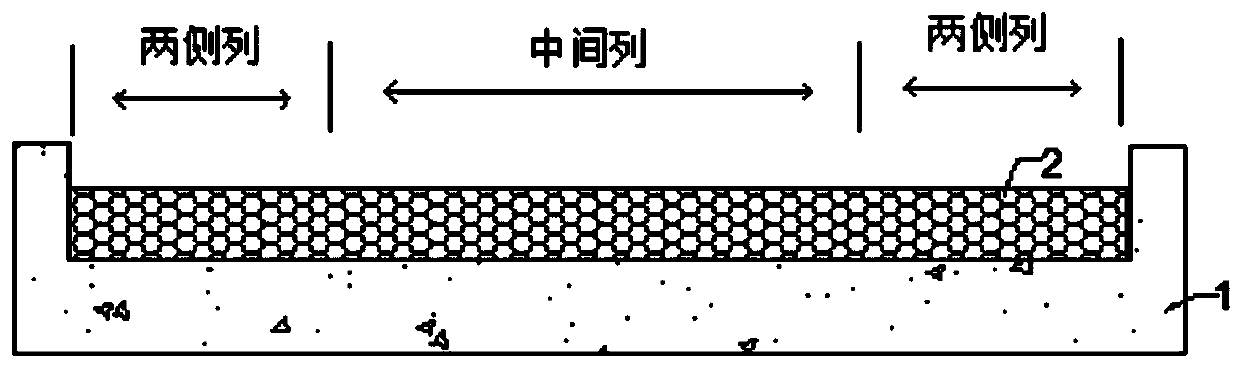

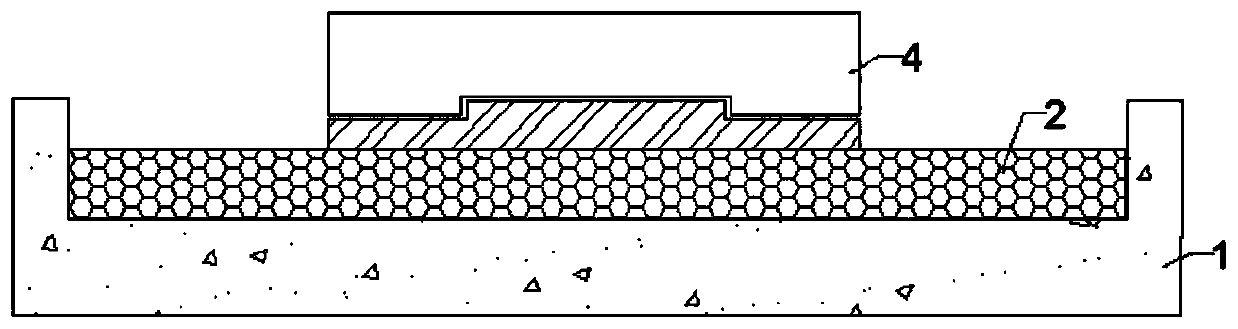

[0029] S2. Pavement paving: including the first paving and the second paving;

[0030] The first paving: Divide the expressway into the same two columns according to the width for paving, such as figure 1 As shown, each column uses a paver to lay the asphalt filler on the subgrade 1. The paving temperature of the asphalt filler is controlled between 170 and 175°C. The paver is laid in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com