Novel compound deck repairing layer for concrete beam bridge

A concrete and repair layer technology, applied in bridge maintenance, bridges, bridge parts, etc., can solve problems such as aggravating bridge deck cracks, steel corrosion, affecting the safety of bridge structures, etc., and achieve the effect of increasing service life and increasing tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

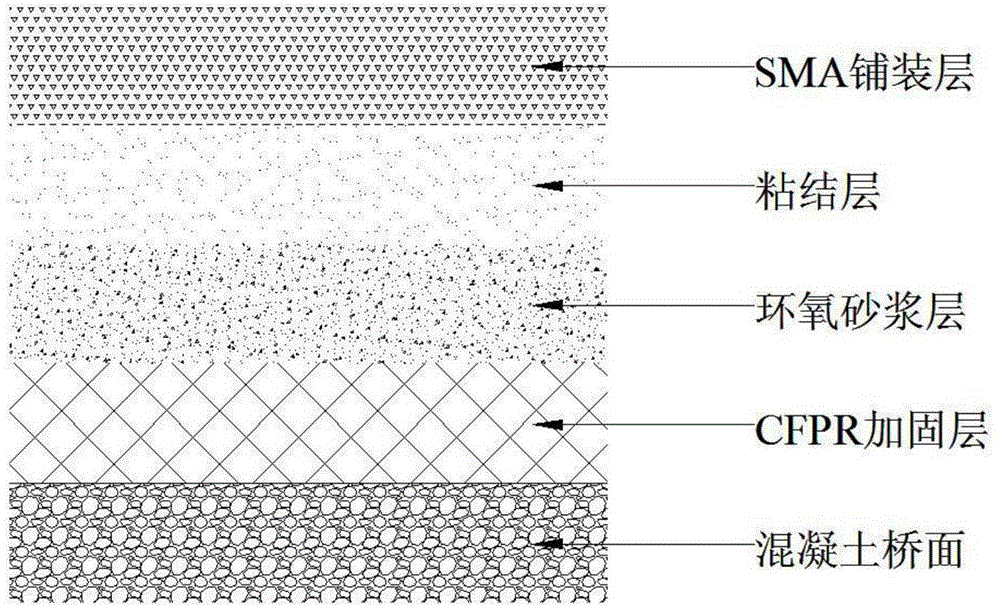

[0031] Embodiment 1, a kind of novel composite bridge deck repair layer that is used for concrete girder bridge, as figure 1 As shown, the bridge deck repair layer includes carbon fiber plate reinforcement layer, epoxy mortar layer and asphalt mastic macadam concrete pavement layer.

[0032] The carbon fiber board is drawn into a mold by mixing carbon fiber filaments with diphenol-based propane epoxy resin cured by methyltetrahydrophthalic anhydride and DMP-30. Among them, methyltetrahydrophthalic anhydride and DMP-30 are diphenol-based propane epoxy resin: methyltetrahydrophthalic anhydride: DMP-30=100:80:2 to treat diphenol according to the mass ratio propane epoxy resin.

[0033] Epoxy mortar is composed of diphenol-based propane epoxy resin, 1,4-butanediol diglycidyl ether, polypropylene glycol diglycidyl ether, amine curing agent, and quartz sand according to the mass ratio of diphenol-based propane epoxy resin : 1, 4-butanediol diglycidyl ether: polypropylene glycol di...

Embodiment 2

[0045] Embodiment 2, a kind of novel composite bridge deck repair layer that is used for concrete girder bridge, as figure 1 As shown, the bridge deck repair layer includes carbon fiber plate reinforcement layer, epoxy mortar layer and asphalt mastic macadam concrete pavement layer.

[0046] The carbon fiber board is drawn into a mold by mixing carbon fiber filaments with diphenol-based propane epoxy resin cured by methyl hexahydrophthalic anhydride and DMP-30. Among them, methylhexahydrophthalic anhydride and DMP-30 are diphenol-based propane epoxy resin: methylhexahydrophthalic anhydride: DMP-30=100:100:4 according to the mass ratio of diphenol propane epoxy resin.

[0047] Epoxy mortar is composed of diphenol-based propane epoxy resin, 1,4-butanediol diglycidyl ether, polypropylene glycol diglycidyl ether, amine curing agent, and quartz sand according to the mass ratio of diphenol-based propane epoxy resin : 1, 4-butanediol diglycidyl ether: polypropylene glycol diglycidy...

Embodiment 3

[0059] Embodiment 3, a kind of novel composite deck repair layer for concrete girder bridge, as figure 1 As shown, the bridge deck repair layer includes carbon fiber plate reinforcement layer, epoxy mortar layer and asphalt mastic macadam concrete pavement layer.

[0060] The carbon fiber board is drawn into a mold by mixing carbon fiber filaments with diphenol-based propane epoxy resin cured by methyl hexahydrophthalic anhydride and DMP-30. Among them, methylhexahydrophthalic anhydride and DMP-30 are diphenol-based propane epoxy resin: methylhexahydrophthalic anhydride: DMP-30=100:90:6 to treat diphenol according to the mass ratio propane epoxy resin.

[0061] Epoxy mortar is composed of diphenol-based propane epoxy resin, 1,4-butanediol diglycidyl ether, polypropylene glycol diglycidyl ether, amine curing agent, and quartz sand according to the mass ratio of diphenol-based propane epoxy resin : 1, 4-butanediol diglycidyl ether: polypropylene glycol diglycidyl ether: amine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com