Fast assembly type anti-explosion protective plate for steel bridge main girders and method for manufacturing and assembling fast assembly type anti-explosion protective plate

A protective plate, assembled technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of reducing peak stress, high construction cost, general anti-explosion protection effect, etc., to reduce dynamic response and prevent softening and buckling. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

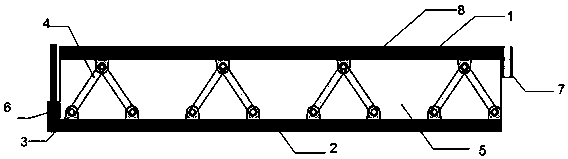

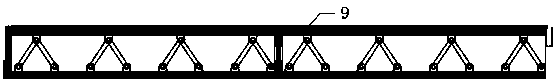

[0042] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0043] The assembled anti-blast protection plate structure of the present invention is composed of a plurality of assembled anti-blast protection plates, and each assembled anti-blast protection plate includes a top steel plate, a bottom steel plate, an energy-dissipating soft steel rod, and a middle filler Foamed aluminum layer, basalt fiber cloth and SMA flame-retardant asphalt concrete wear layer. The energy-dissipating soft steel rod refers to the steel rod made of mild steel, which has a certain energy-dissipating capacity.

[0044] in:

[0045] The thickness of the top steel plate is 3-5 cm.

[0046] The thickness of the bottom steel plate is 1-3cm.

[0047] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com