Patents

Literature

44results about How to "Insulate from high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

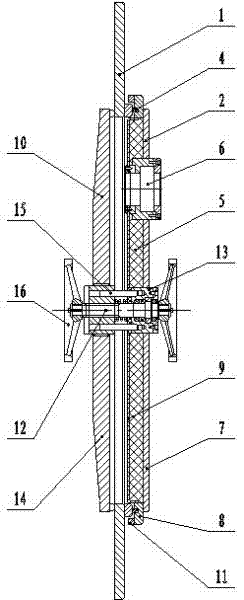

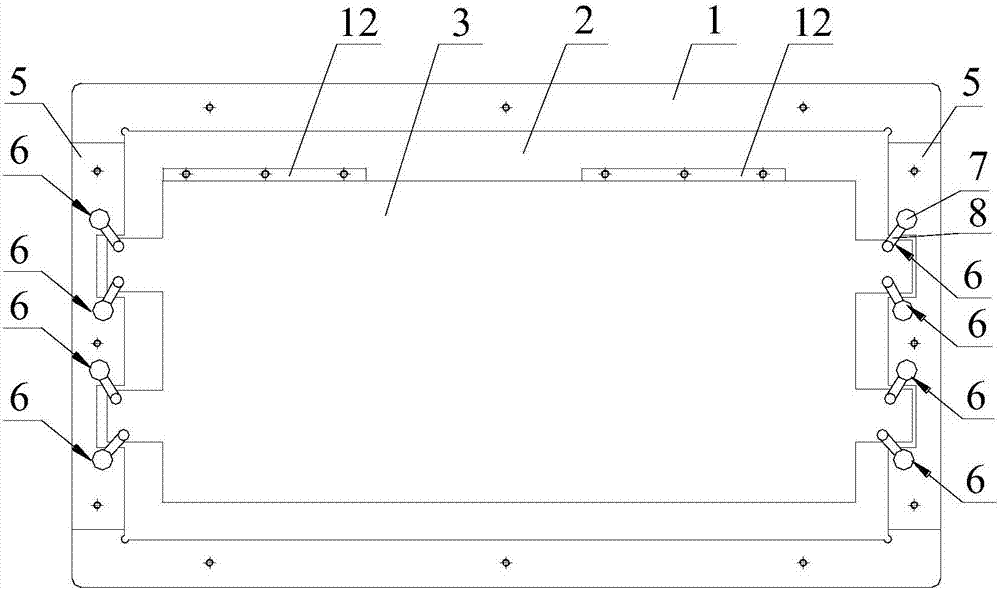

Capsule door of rescue capsule used for mine

ActiveCN102383704AReduce cooling costsGood heat insulationFireproof doorsConstruction fastening devicesLocking mechanismElectrical and Electronics engineering

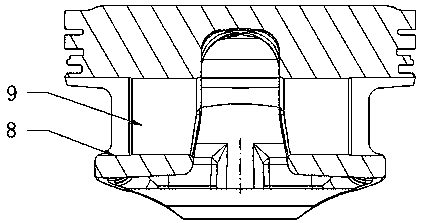

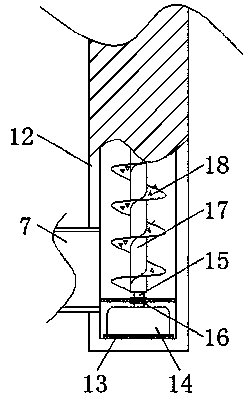

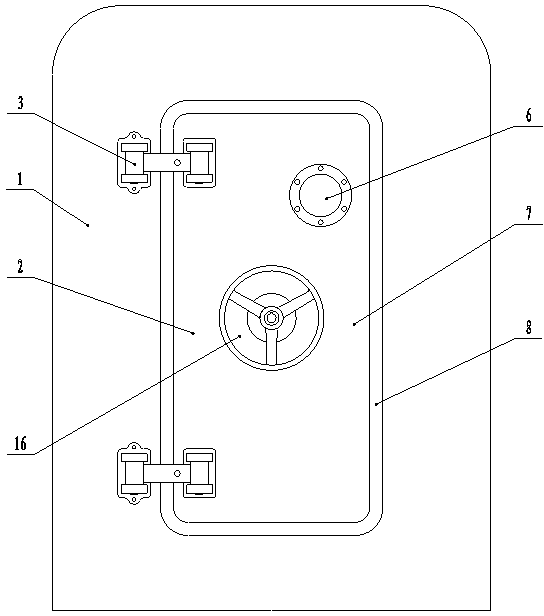

The invention discloses a capsule door of a rescue capsule used for a mine, belongs to the technical field of capsule doors of rescue capsules and aims at providing a capsule door of a rescue capsule for a mine, wherein the capsule door is provided with a thermal insulating layer and has a good sealing effect. The technical scheme adopted by the invention is as follows: the capsule door of the rescue capsule used for the mine comprises a door frame, a door, hinges, a sealing strip, a thermal insulating material and an observation window, wherein the door is connected to the door frame by virtue of the two hinges; one circle of sealing strip is arranged between the door frame and the door; and the door is provided with the observation window. The capsule door is structurally characterized in that one circle of flitch is fixed on a door plank; a stainless steel trim plate is fixed on the flitch; the thermal insulating material is installed in a sealed space among the door plank, the flitch and the stainless steel trim plate; and the door is provided with a locking mechanism which can press the door onto the door frame. The capsule door can be applied to the rescue capsule under the mine.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

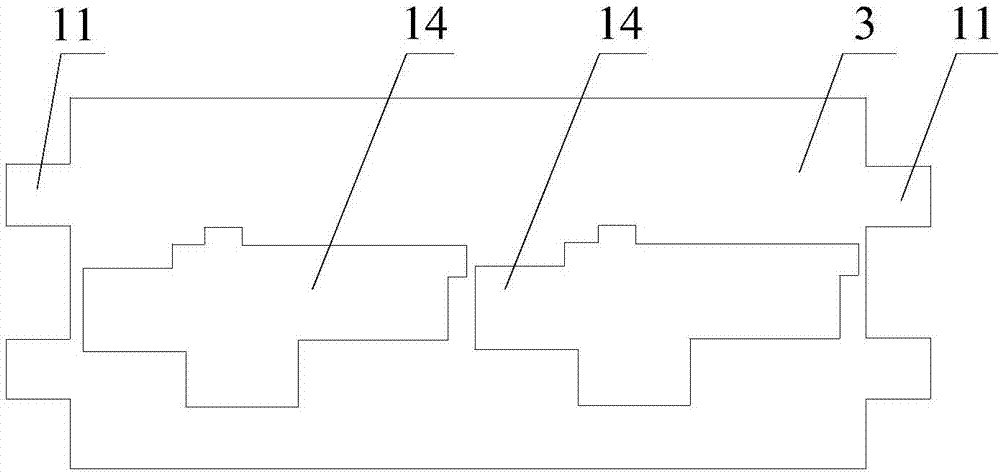

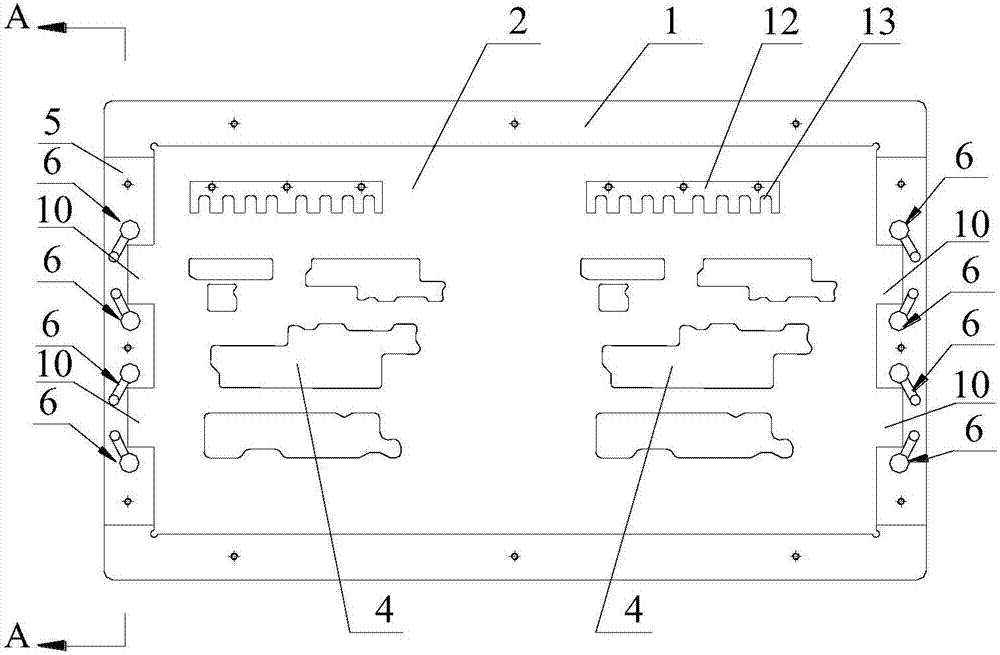

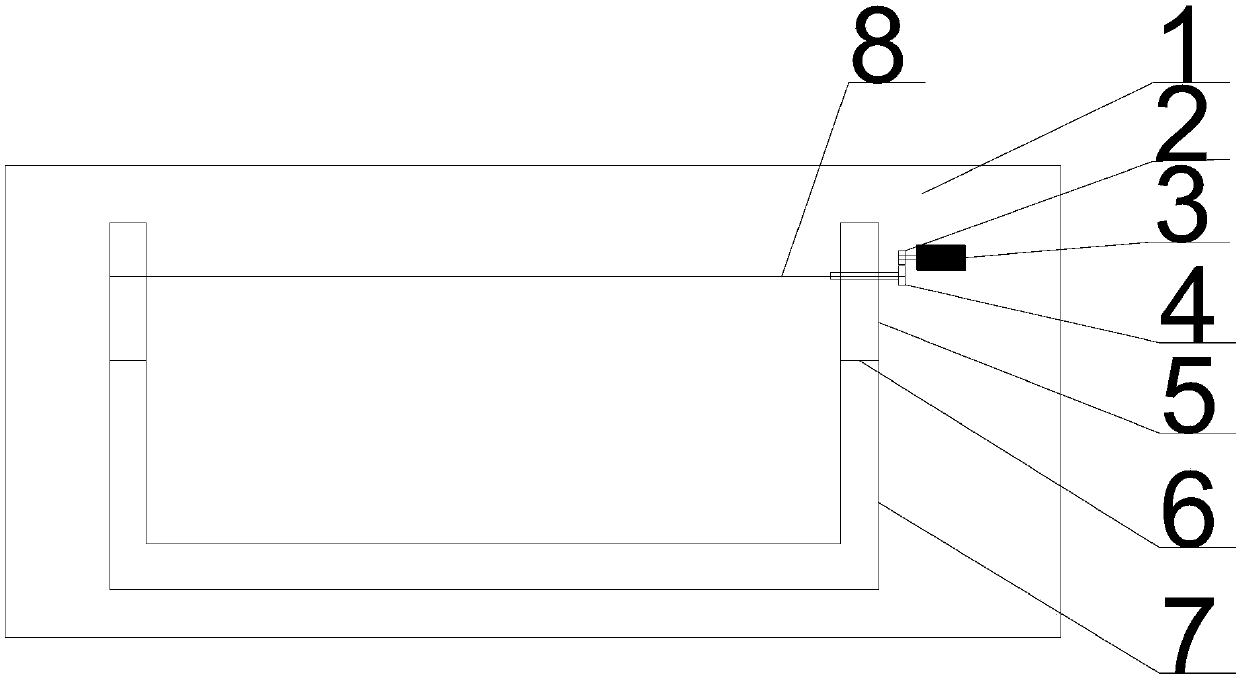

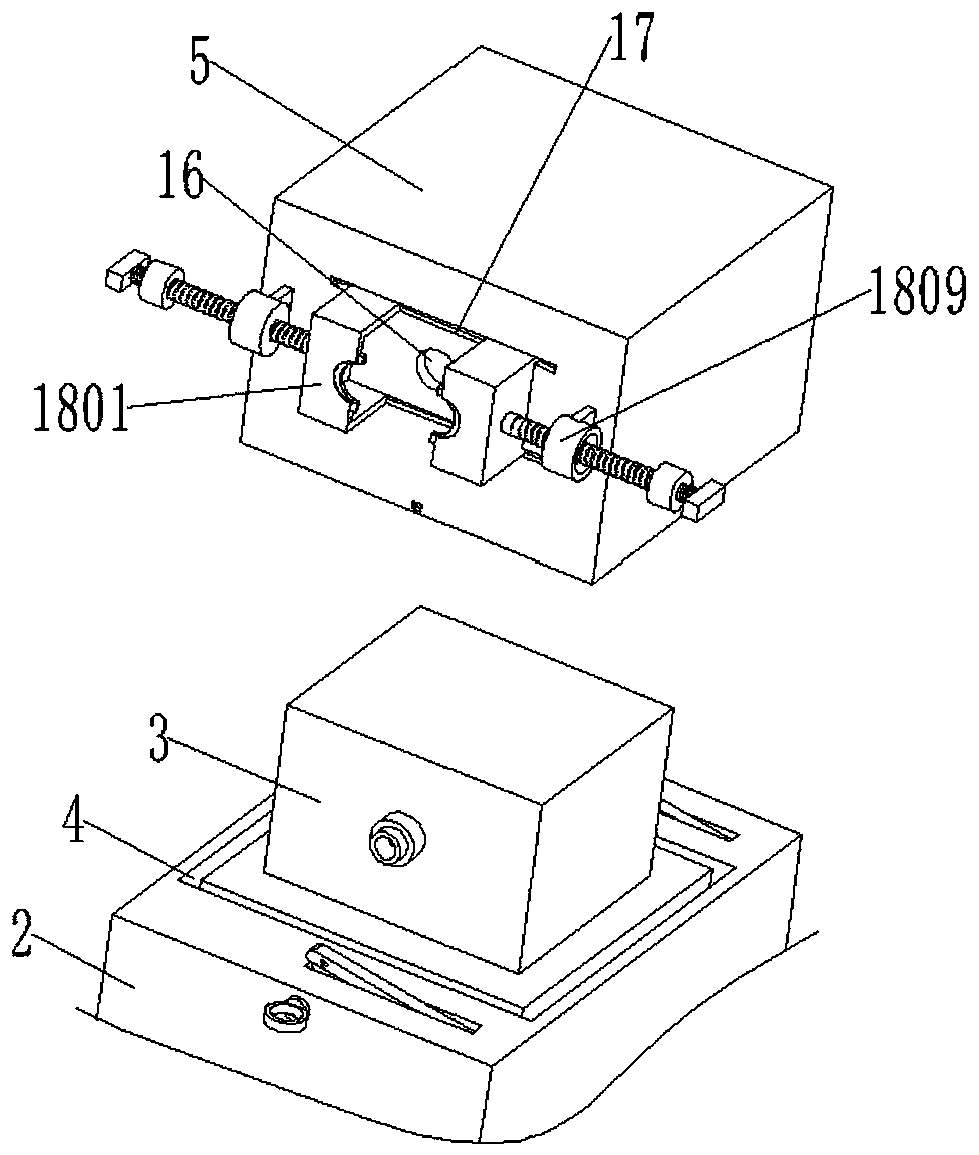

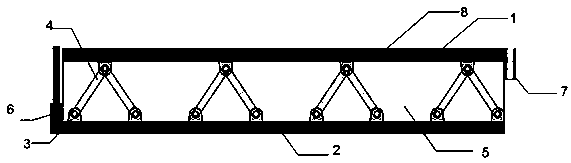

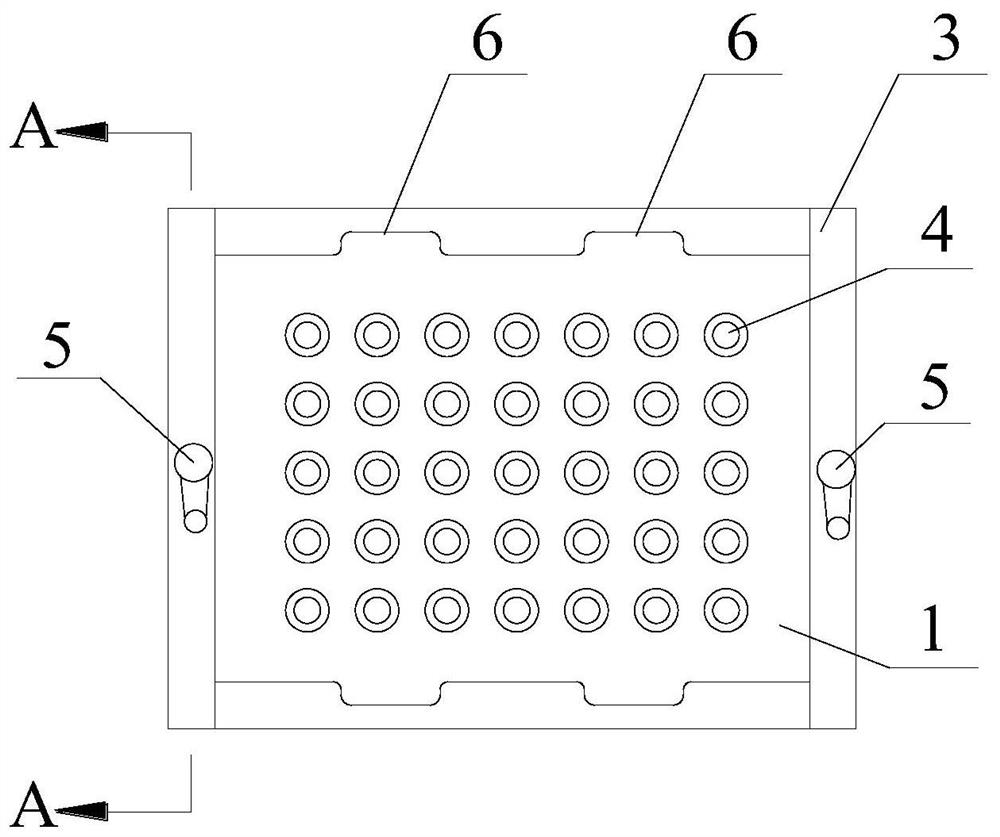

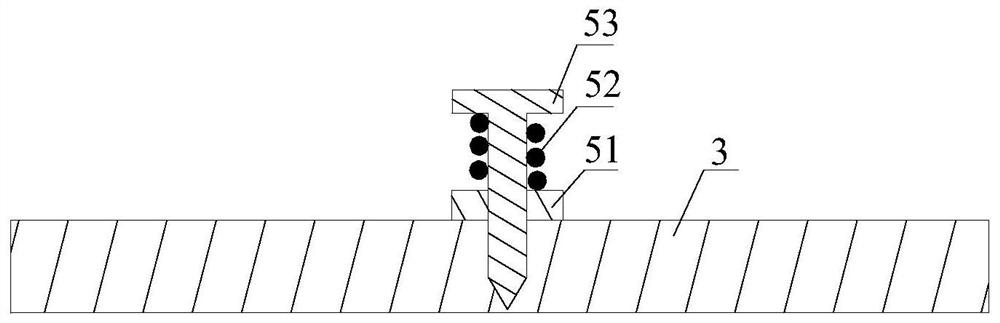

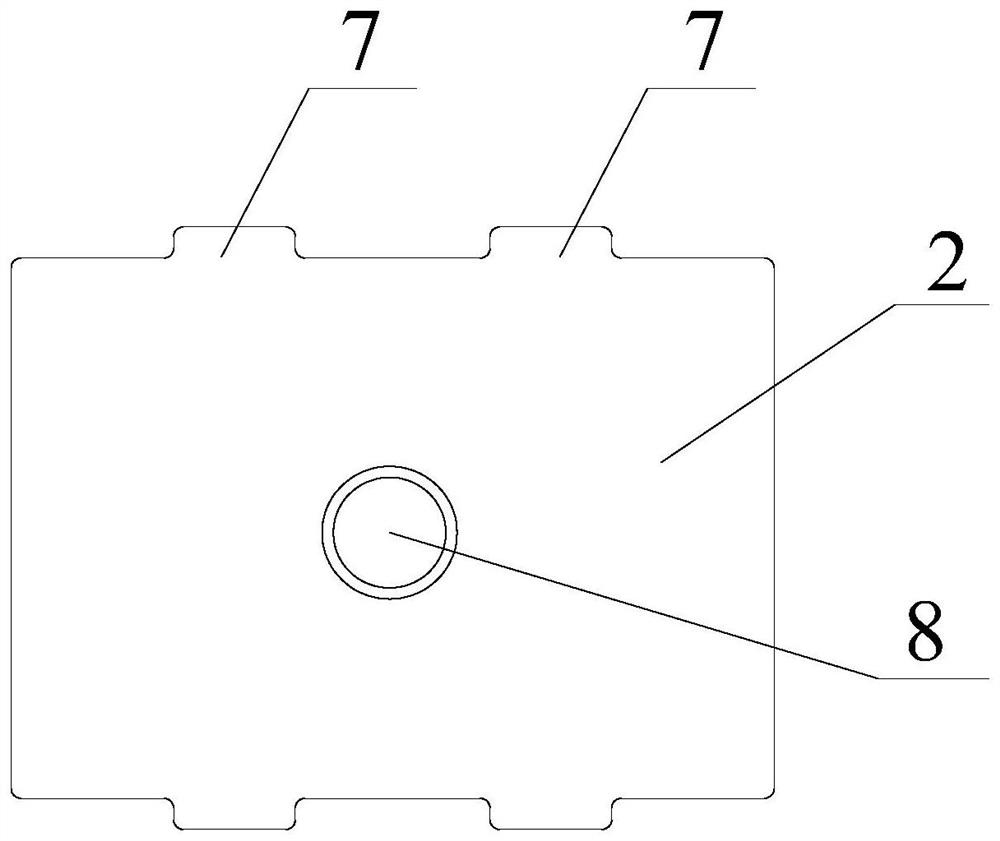

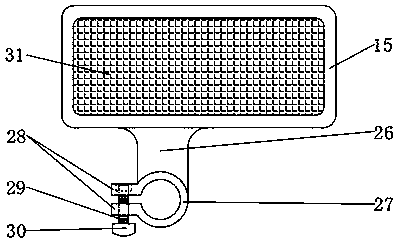

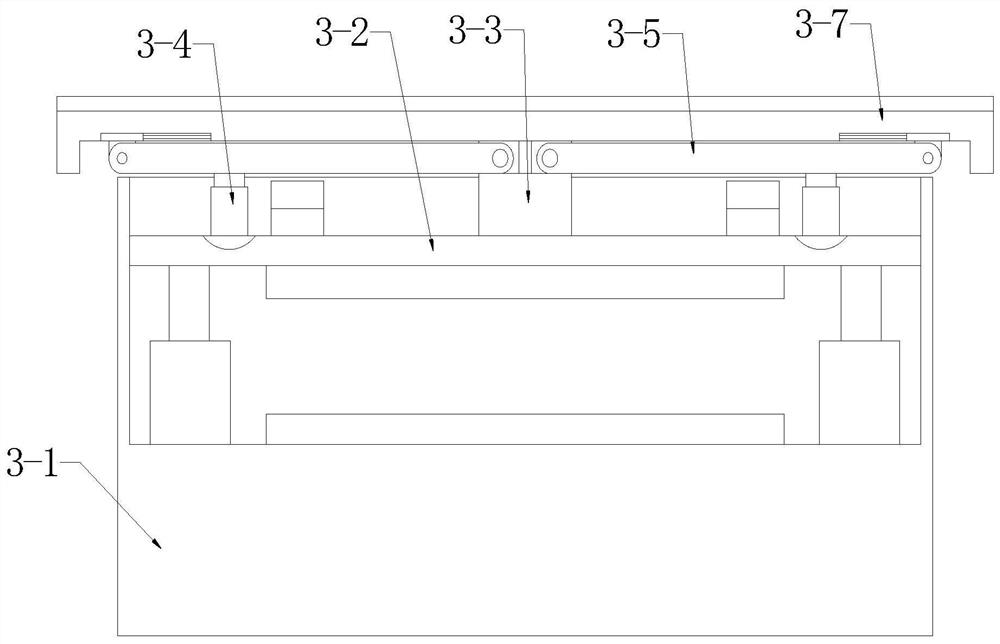

Wave soldering clamp and method for optical device

ActiveCN107262869ASimple structureIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLED lamp

The invention discloses a wave soldering clamp and method for an optical device and relates to the field of wave soldering clamps. The clamp is used for soldering the optical device on a PCB (Printed Circuit Board); the clamp comprises an edge frame, a bottom plate and a cover plate, wherein the edge frame is fixedly connected with the bottom plate; the bottom plate is provided with at least one soldering hole for soldering the optical device; at least one clamping assembly is arranged at each of two sides of the edge frame; the cover plate covers the bottom plate through the clamping assemblies; at least one PCB can be arranged between the bottom plate and the cover plate; at least one yielding groove is formed in one side, close to the PCB, of the cover plate; the shape of the yielding groove is matched with the shape of the optical device on the PCB; the bottom plate is provided with at least one LED (Light Emitting Diode) lamp positioning plate; and a plurality of LED lamp positioning grooves are formed in the LED lamp positioning plate. The method comprises steps of putting the PCB in the clamp and then carrying out automatic wave soldering. By adopting the wave soldering clamp and method for the optical device, disclosed by the invention, the soldering quality of the optical device can be ensured and the soldering efficiency of the optical device is improved.

Owner:湖北兆元科技有限公司

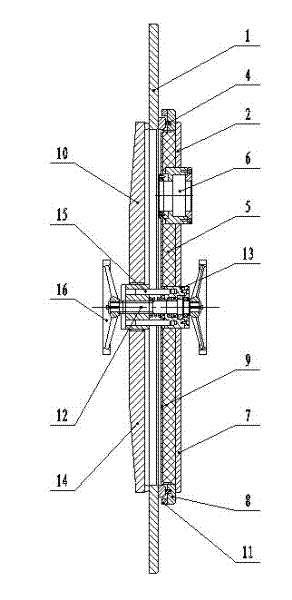

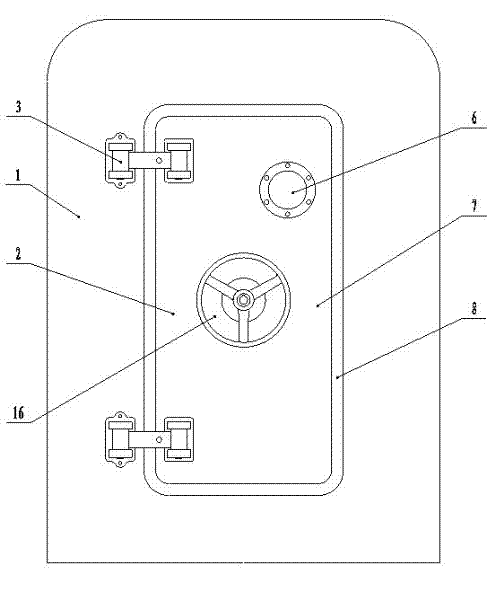

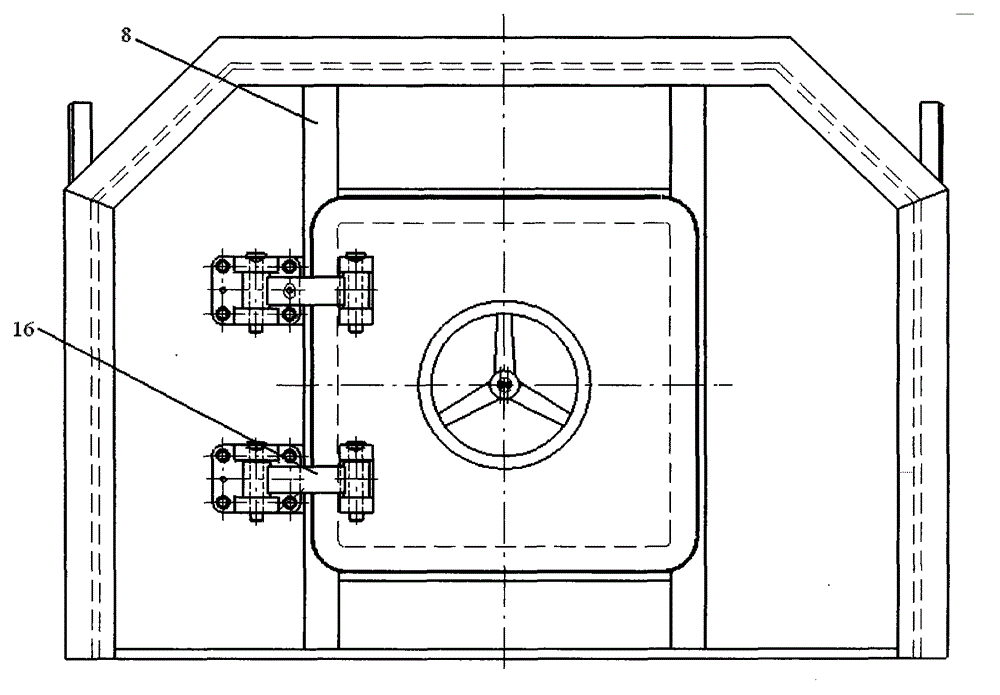

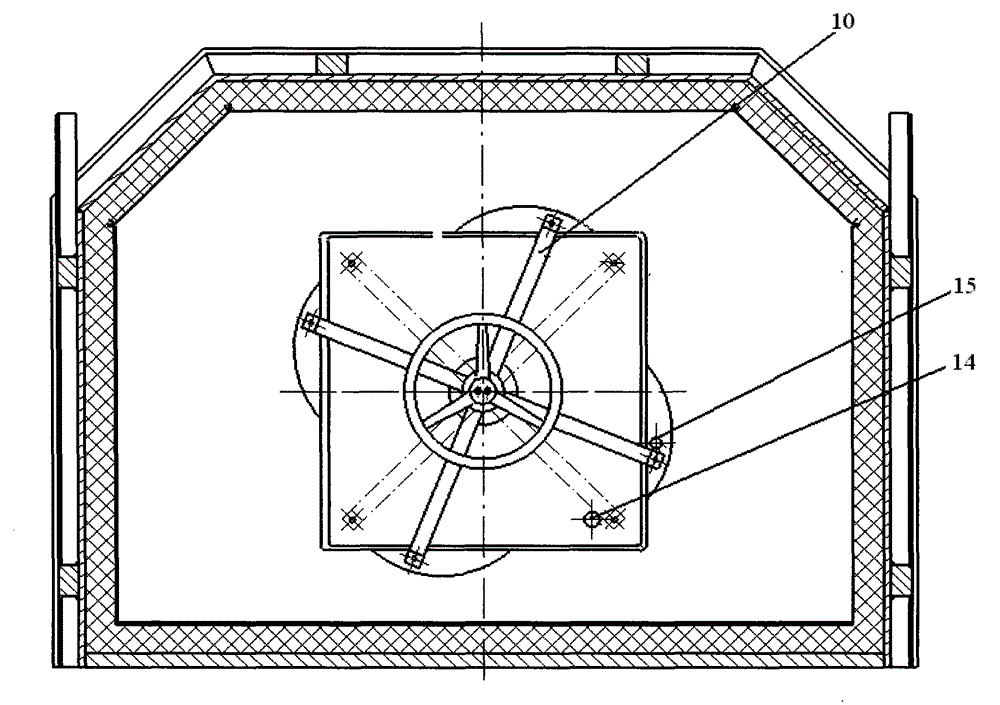

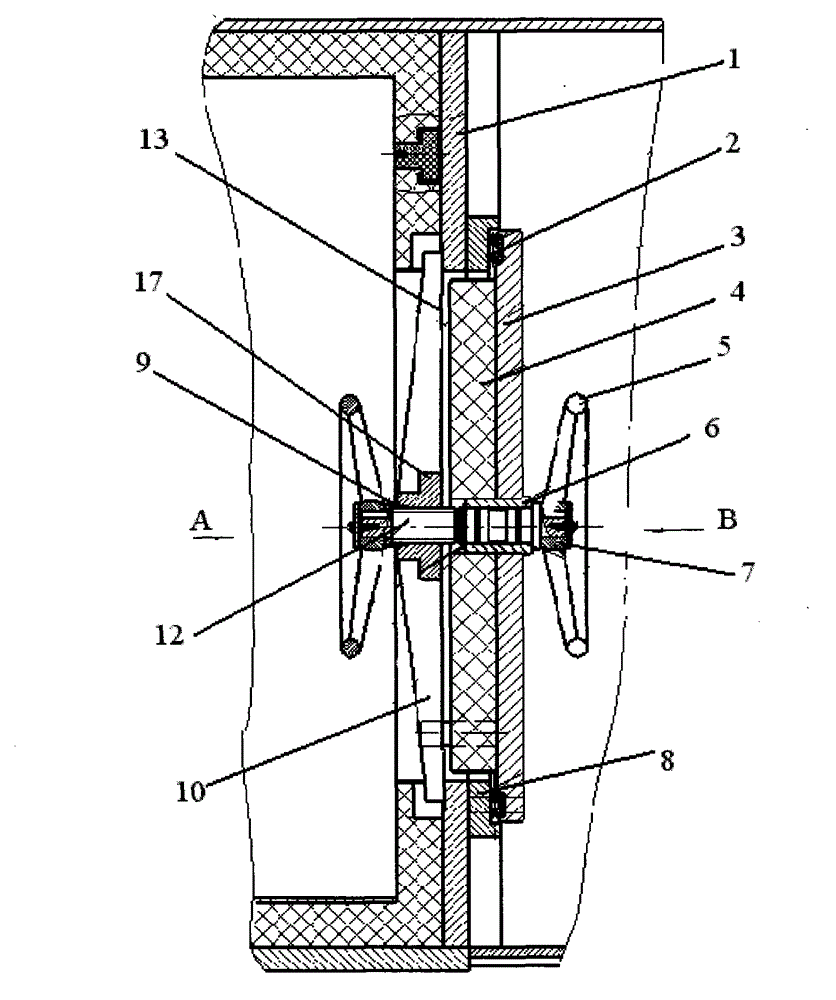

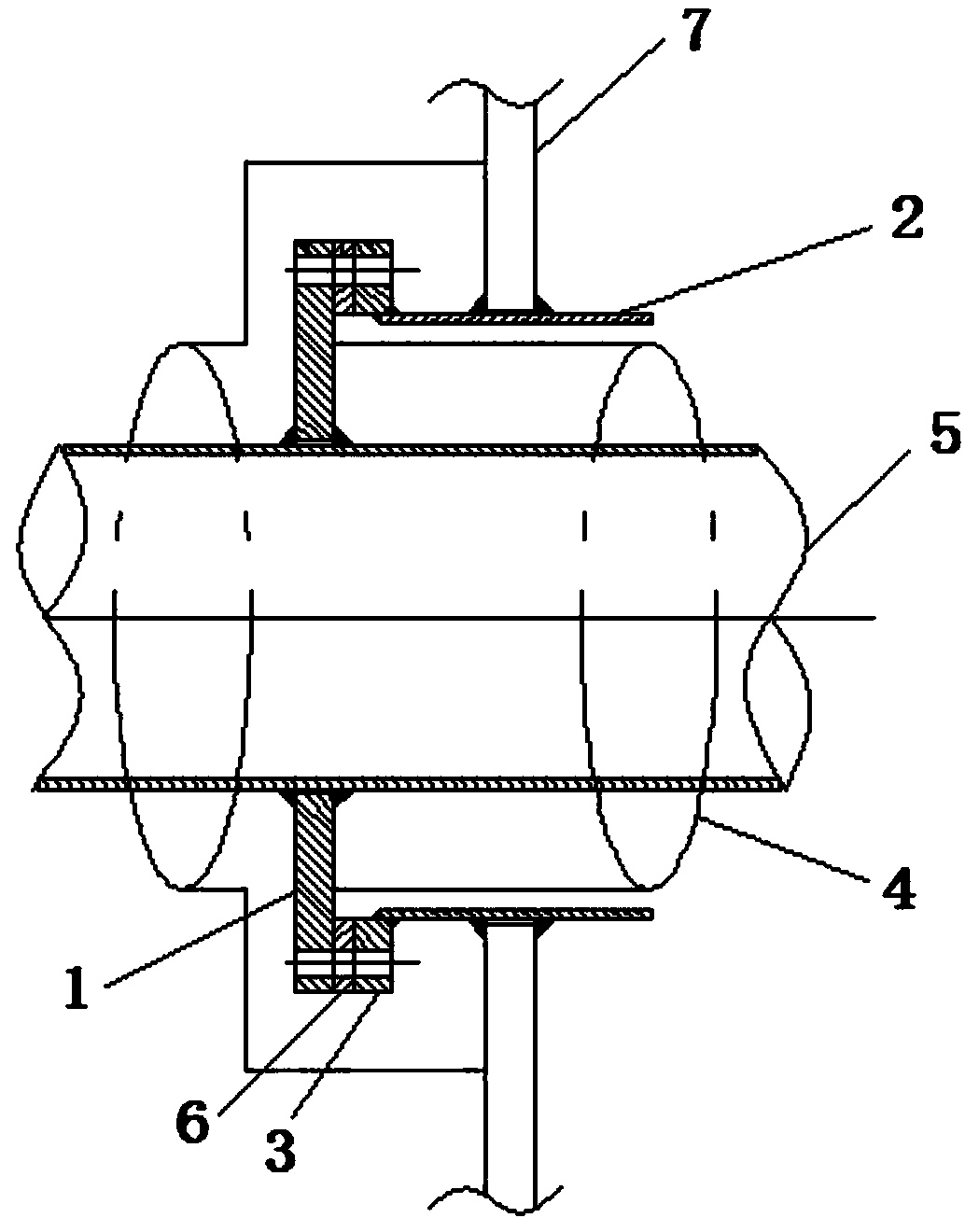

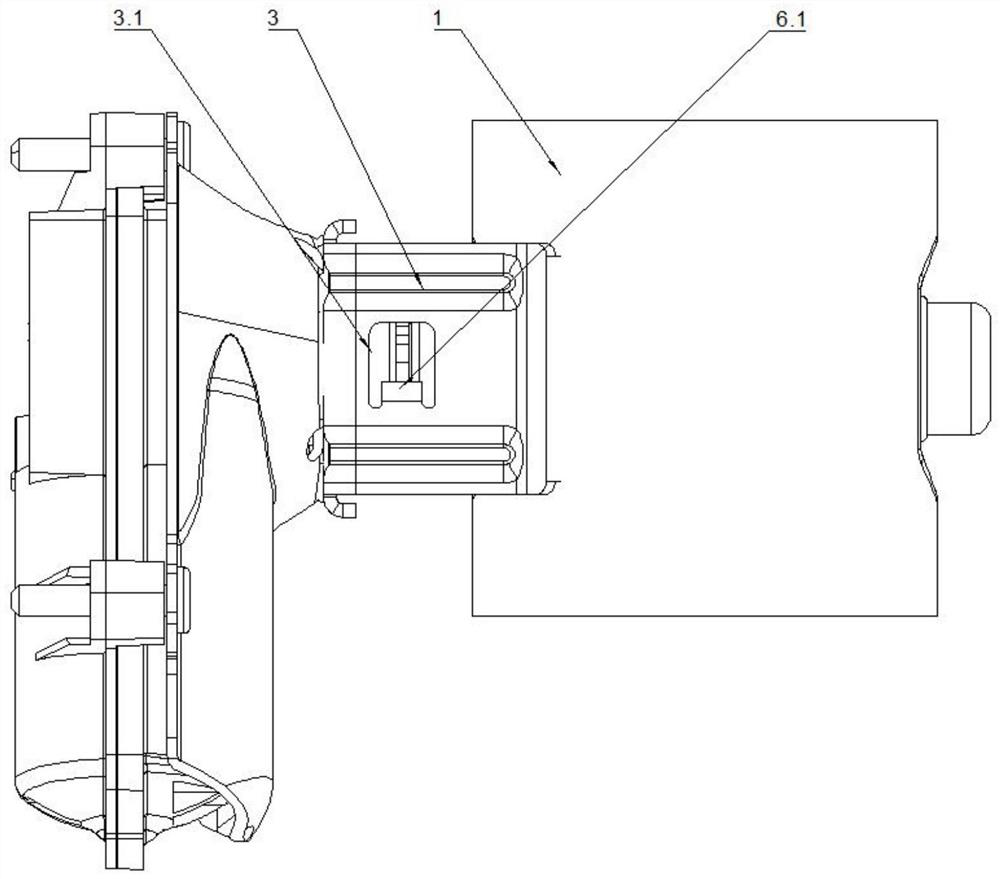

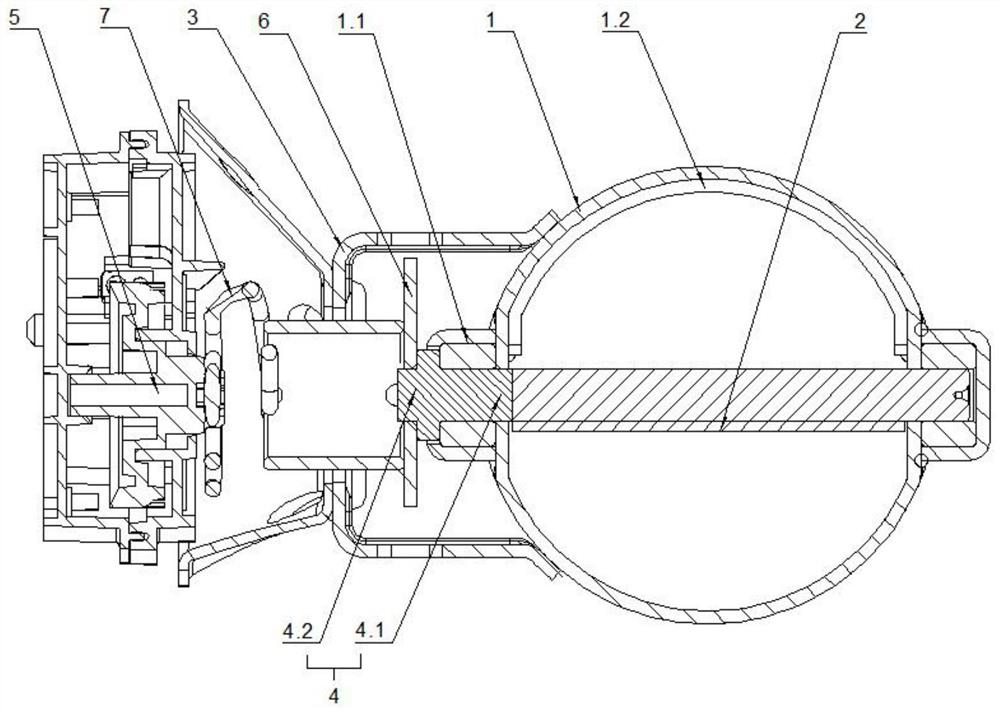

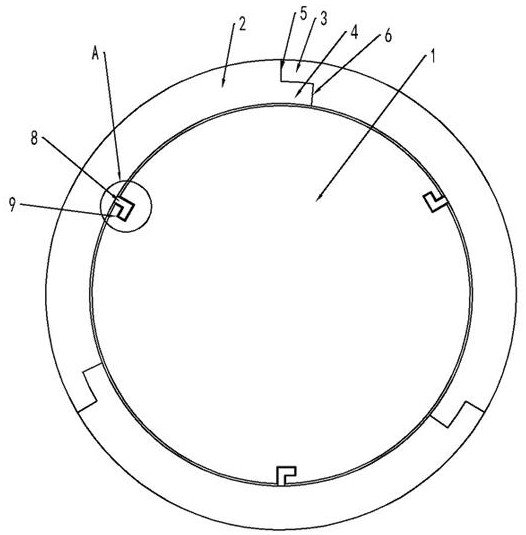

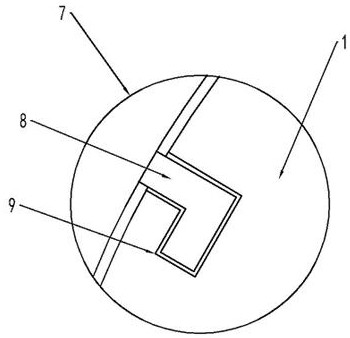

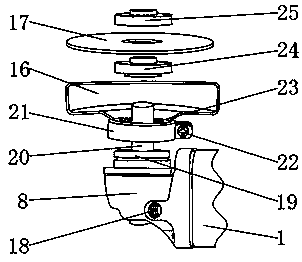

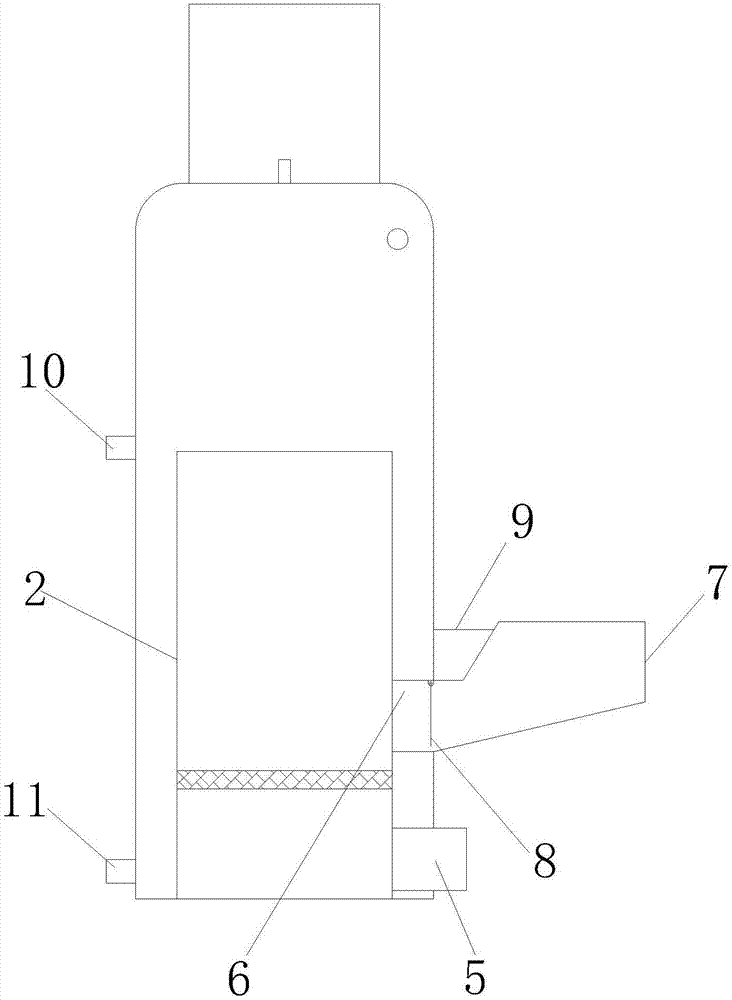

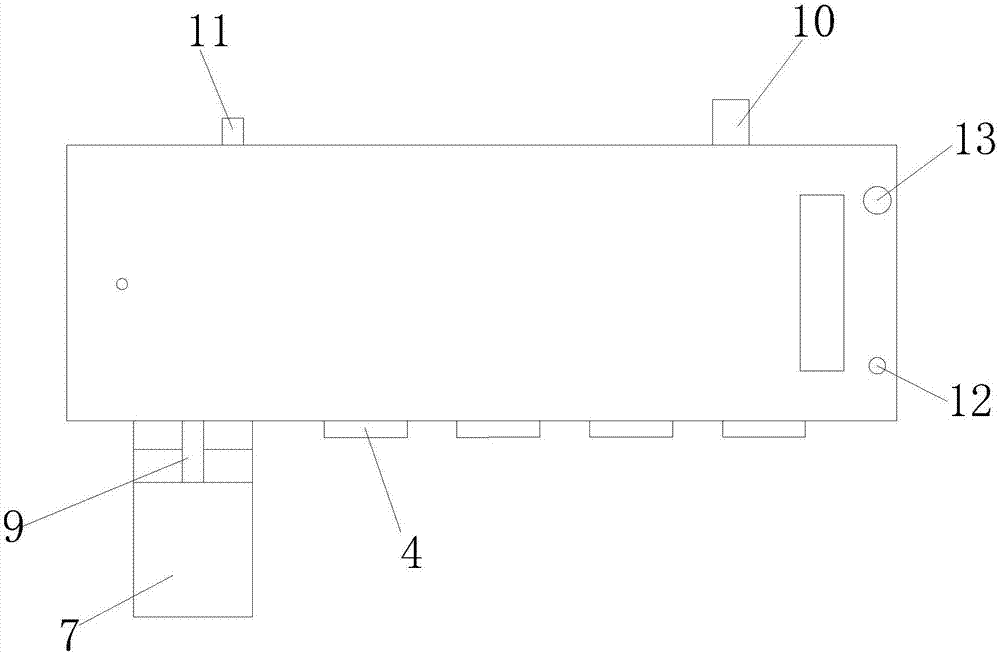

Movable hard rescue capsule emergency door

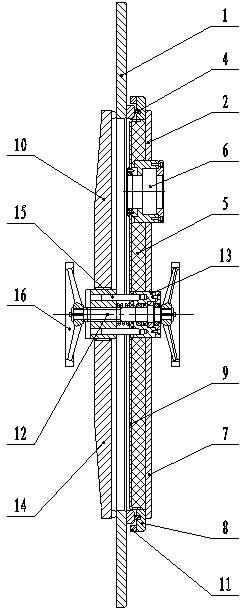

InactiveCN102865021AHigh working reliabilityImprove sealingGasproof doorsFireproof doorsEngineeringWall plate

The invention relates to a movable hard rescue capsule emergency door, which comprises a door wall plate, a door plate, a heat insulating material, a crossed latch, a fixed sleeve, a conical sleeve, a door shaft, two hand wheels, an inner lining plate, a door frame, a first limiting pin and a second limiting pin, wherein a cavity between the inner lining plate and the door plate is filled with the heat insulating material; the crossed latch is positioned outside the inner lining plate; a through hole is formed in the centers of the door plate, the inner lining plate and the heat insulating material; the fixed sleeve is welded in the through hole of the door plate; the door shaft penetrates through the conical sleeve, the crossed latch and the fixed sleeve from inside to outside of a capsule in sequence; the conical sleeve corresponds to a conical hole in the top of a nut and the sizes are the same; the two ends of the door shaft are provided with one hand wheel respectively; the door plate is provided with the first limiting pin on the inner side of the capsule; and the door wall plate is provided with the second limiting pin on the inner side of the capsule. The movable hard rescue capsule emergency door has the characteristics of better heat insulating and sealing effects and high reliability and can be widely applied to the field of mining.

Owner:HENAN POLYTECHNIC UNIV

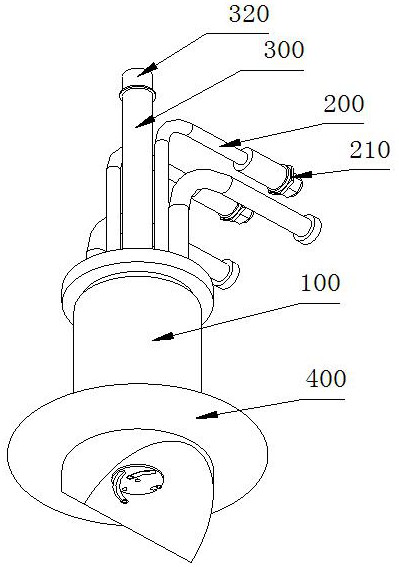

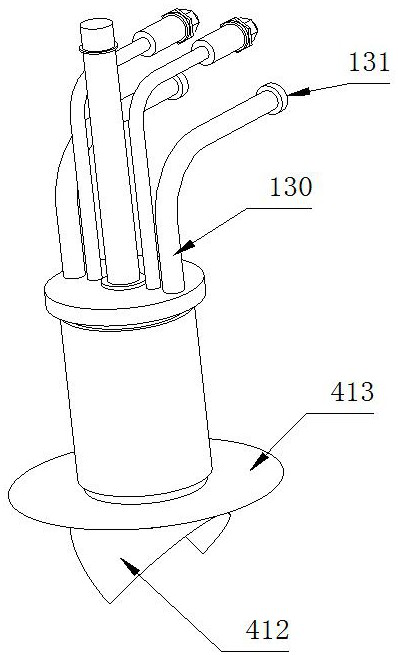

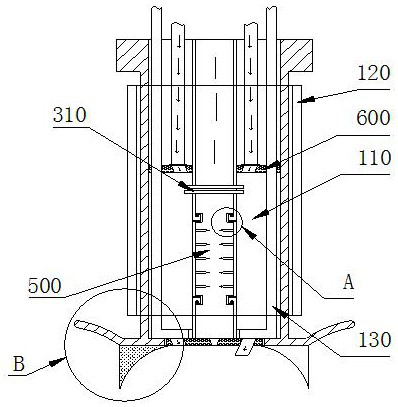

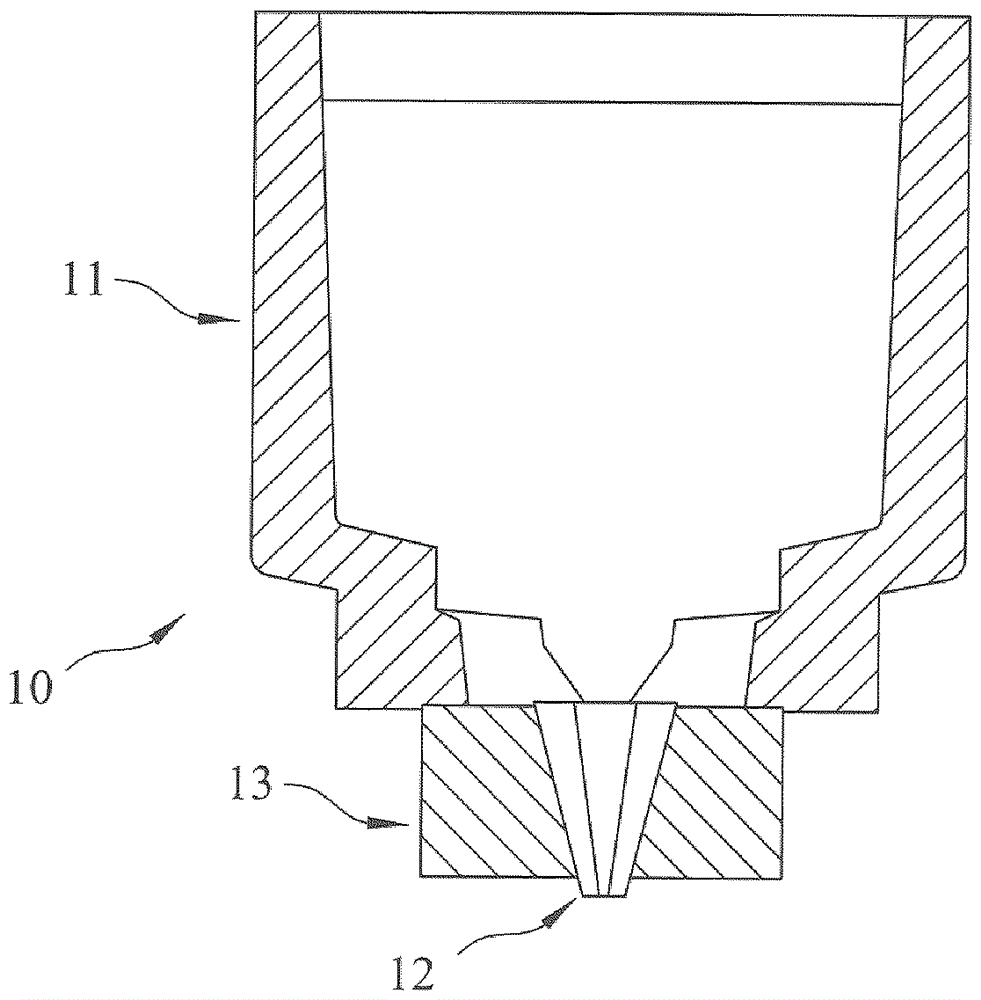

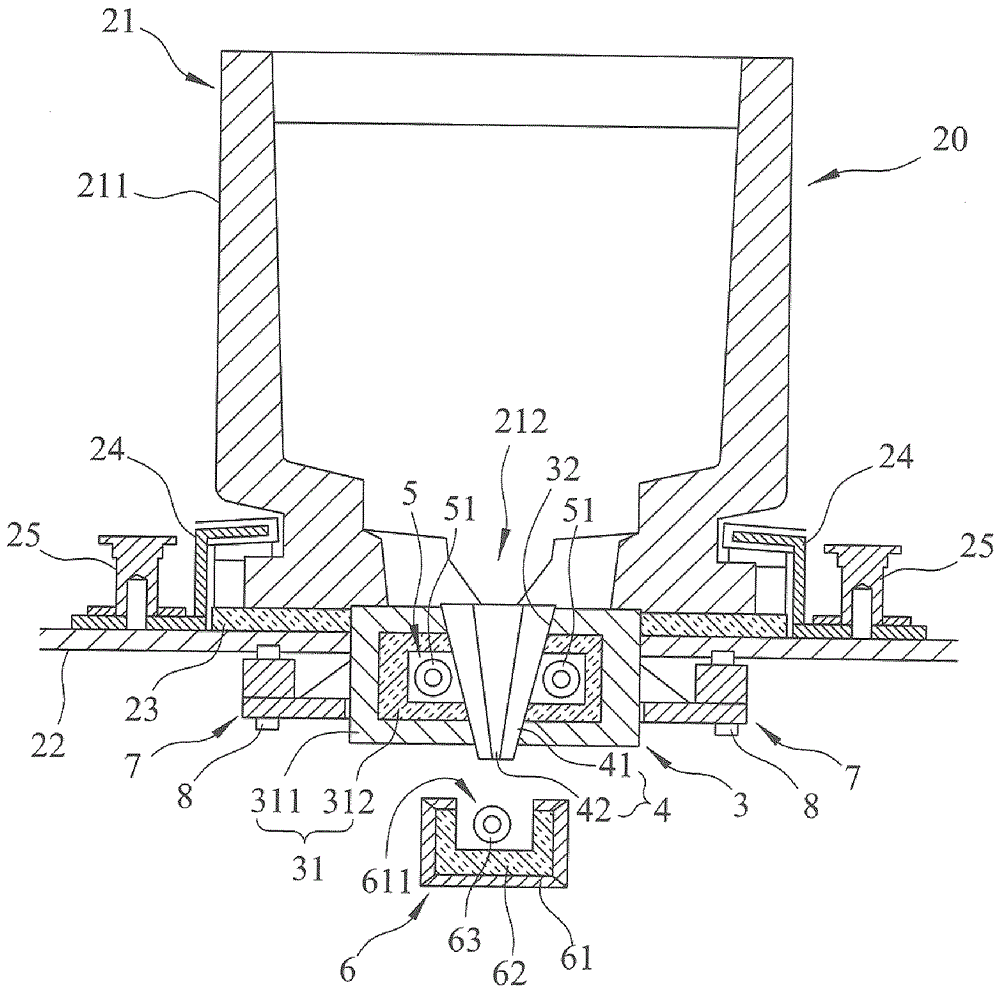

Nozzle device

The invention provides a nozzle device mounted on a casting device. The casting device comprises a crucible for accommodating molten steel; and the crucible has a main body and an output port. The nozzle device comprises a support base, a nozzle arranged in the support base, and a first heating unit for heating the nozzle. The support base comprises a base body; and the base body has a stainless steel layer, and a first heat insulation layer positioned at the inner side of the stainless steel layer. The upper end of the nozzle is combined at the bottom of the main body, and is communicated with the output port. The first heating unit comprises two first heating pieces arranged in the base body at an interval and used for heating the nozzle. Therefore, the first heating pieces can heat the nozzle to prevent the molten steel from condensing when flowing through the nozzle; and the first heat insulation layer of the base body can effectively isolate high temperature, and fits the stainless steel layer to improve the whole rigidity, thereby improving cracks caused by high-temperature thermal shock.

Owner:CHINA STEEL

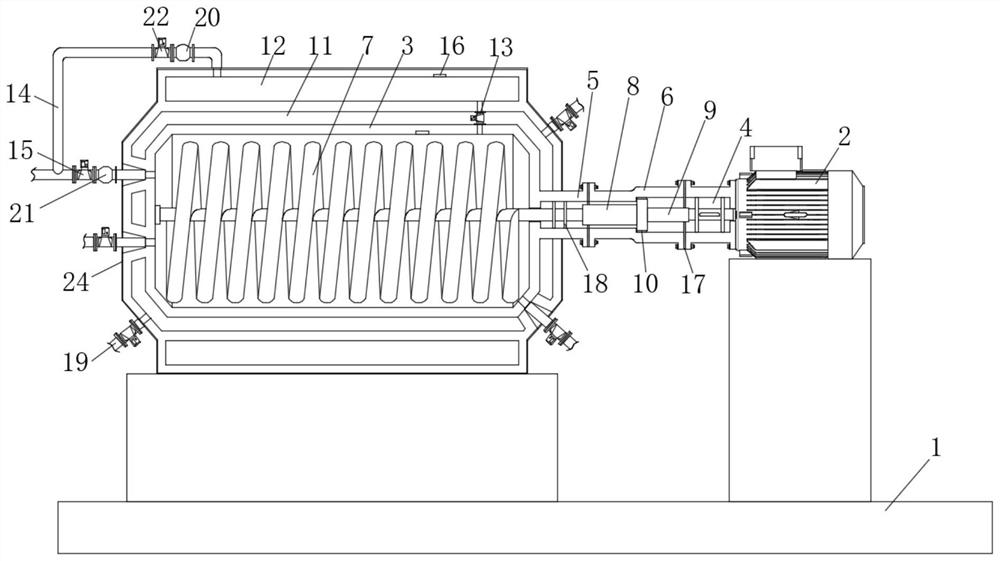

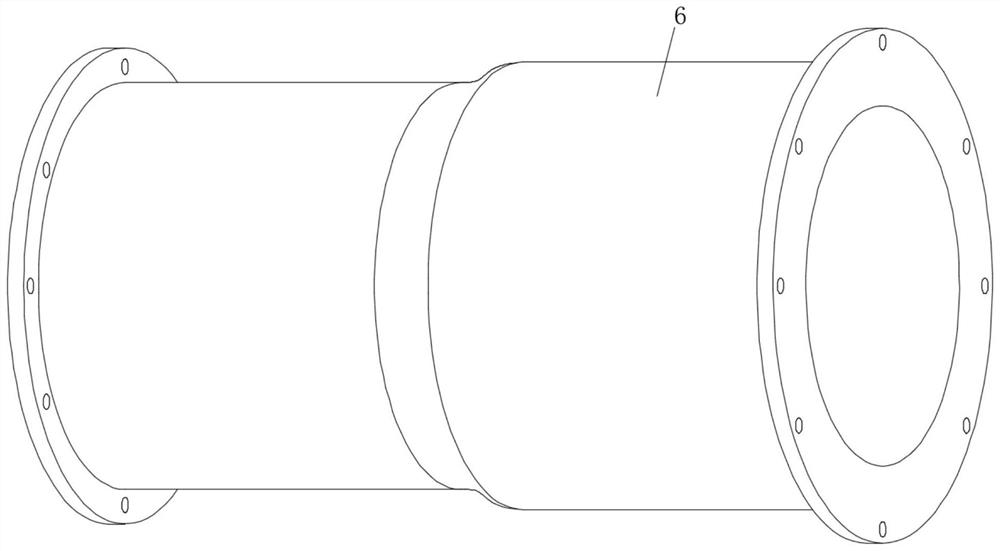

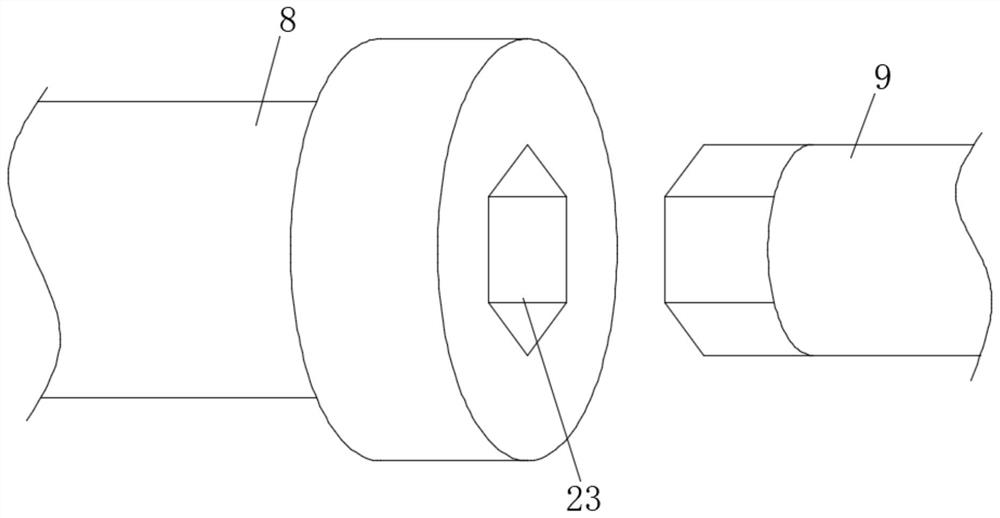

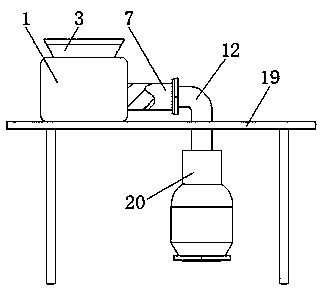

Explosion-proof gas compressor with high safety

InactiveCN112524057AReduce the impactPrevent leakagePump componentsPump controlGas compressorElectric machinery

The invention discloses an explosion-proof gas compressor with high safety, and belongs to the field of gas compressors. The explosion-proof gas compressor with high safety comprises an installation base; an explosion-proof motor and a screw compressor main machine are fixedly installed at the top of the installation base; a screw is rotatably connected inside the screw compressor main machine; afirst butt pipe is fixedly connected to one side, close to the screw compressor main machine, of the explosion-proof motor through a bolt; and a second butt pipe is fixedly connected to one side, close to the explosion-proof motor, of the screw compressor main machine. According to the explosion-proof gas compressor with high safety, compared with the driving connection mode of a traditional compressor, the sealing performance is better, the leakage of inflammable and explosive gases in the screw compressor main machine is avoided, it is ensured that the compression pressure inside the screw compressor main machine is not too high to break a tank body, the safety capability is high, the explosion-proof and leakage-proof effects are better, and the safety is higher compared with the traditional gas compressor.

Owner:BENGBU AUTO COMPRESSOR

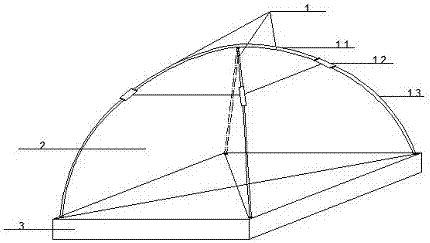

Beach tent

InactiveCN107165474AInsulate from high temperatureReduce the temperatureTents/canopiesEngineeringCushion

The invention discloses a beach tent, which comprises three parts: a tent frame, a tarpaulin and a tent bottom. The tent frame is composed of two arched tent poles and four arc-shaped tent poles. The two arched tent poles intersect to form the vault of the beach tent. Connected by connectors to form the tent frame of the beach tent. The tarpaulin has two layers, the inner tent is a gauze tent, and the outer tent is a rainproof cloth. There are pipes on the outside or ropes on the inside for fixing on the tent pole. The four corners of the tent bottom are embedded with sleeves for fixing the tent frame; when the tent bottom is an air cushion, there are air-filling holes; when the tent bottom is a water cushion, there are water-filling holes. The invention is detachable and easy to carry; the bottom of the canopy is an air cushion or water cushion, which is soft and comfortable, and can effectively insulate the high temperature of the surface of the beach and reduce the temperature inside the canopy; the erection method is simple and easy to learn, and can be operated by one or two people.

Owner:YANCHENG CHANGHUA OUTDOOR PROD CO LTD

Exhaust pipe penetration piece and installation method thereof

PendingCN108082434AInsulation Watertight RequirementsMeet watertight requirementsPropulsion power plantsPropulsive elementsEngineeringExhaust pipe

The invention relates to the technical field of ship piping fittings, and discloses an exhaust pipe penetration piece. The exhaust pipe penetration piece comprises a ring piece, a connecting pipe, a connecting piece and a fireproof and insulating gasket, and the ring piece is provided with an inner ring surface for being fixedly connected with the outer circumferential wall of an exhaust pipe andan outer ring surface extending away from the outer circumferential wall of the exhaust pipe; the connecting pipe is located on one side of the ring piece, and the exhaust pipe is sleeved with the connecting pipe; an insulating space is formed between the inner circumferential wall of the connecting pipe and the outer circumferential wall of the exhaust pipe, and the outer circumferential wall ofthe connecting pipe is used for fixedly being connected with a bulkhead; and the end part, close to the ring piece, of the connecting pipe is connected with the ring piece through the connecting piece, and the fireproof and insulating gasket is arranged between the connecting pipe and the ring piece. The invention further discloses an installation method of the exhaust pipe penetration piece. Theexhaust pipe penetration piece and the installation method thereof are compatible with the high temperature characteristic and the watertight characteristic required for the exhaust pipe, thereby improving the flexibility of the layout of the exhaust pipe in a cabin.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

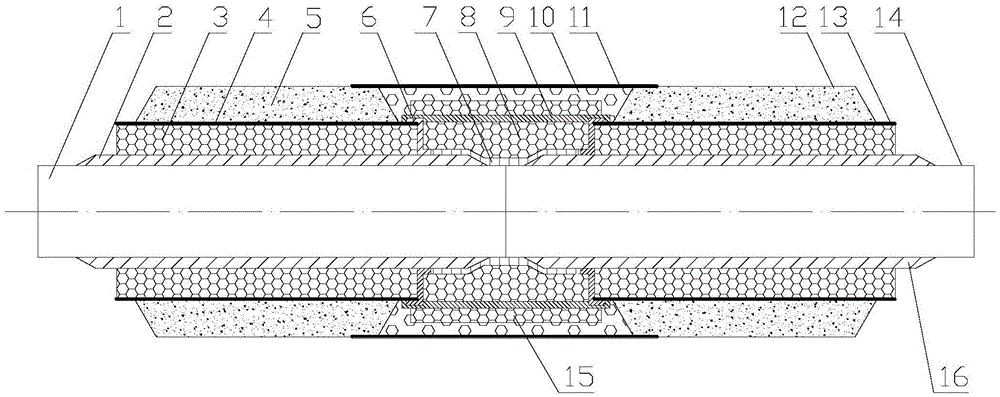

Composite mouth-repairing structure for counterweight layer of large-caliber submarine pipeline

ActiveCN105156831AAvoid the problem of incomplete mold fillingShorten the ripening timePipe elementsOcean bottomHigh density

The invention discloses a composite mouth-repairing structure for a counterweight layer of a large-caliber submarine pipeline. The composite mouth-repairing structure comprises a mouth-repairing anticorrosive coating, a mould layer, ring-direction high-density polyurethane foam tiles and high-density polyurethane foams, wherein the mouth-repairing anticorrosive coating is arranged on outer surfaces of steel tube reserved welding sections and tube body anticorrosive coating mouth-repairing sections of two counterweight tubes, and is connected with tube body anticorrosive coatings on the end surfaces of the mouth-repairing sections of the two counterweight tubes; the two ends of the mould layer are respectively arranged on the outer surfaces of concrete counterweight layer mouth-repairing sections of the two counterweight tubes; the ring-direction high-density polyurethane foam tiles are arranged at the periphery of the mouth-repairing anticorrosive coating; the thicknesses of the ring-direction high-density polyurethane foam tiles are smaller than those of the concrete counterweight layers by 30-50mm; and the high-density polyurethane foams are filled between the ring-direction high-density polyurethane foam tiles and the mould layer in a site casting mode, and are integrated with the ring-direction high-density polyurethane foam tiles and the mould layer to coat the outer side of the mouth-repairing anticorrosive coating. According to the technical scheme disclosed by the invention, the technical problems that open-cell polyurethane foams are cured prematurely, mould filling is incomplete and time for reaching strength required by laying is long during filling construction of the counterweight layer of the large-caliber submarine pipeline in the prior art are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

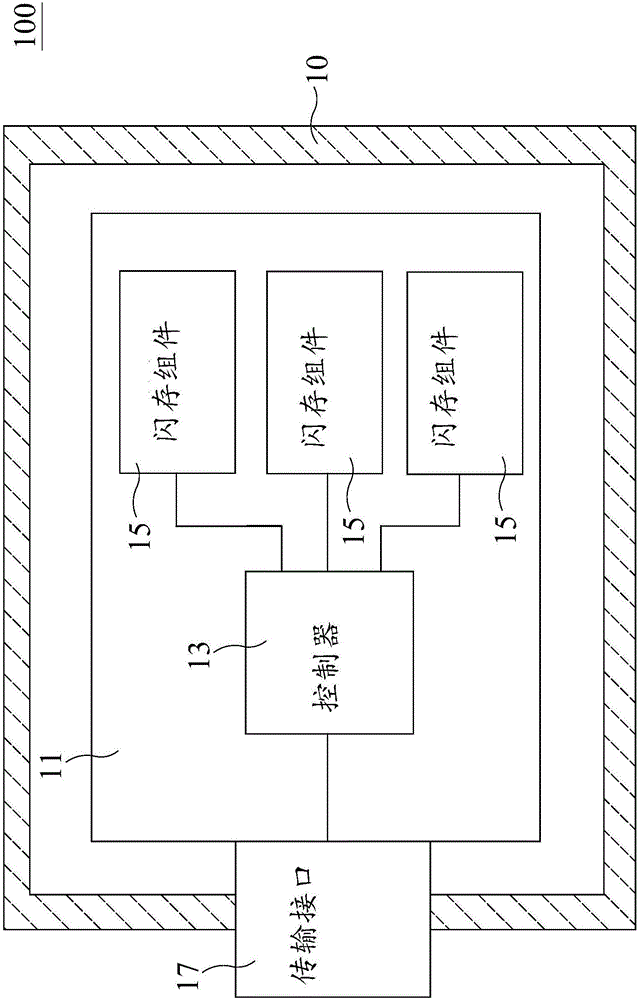

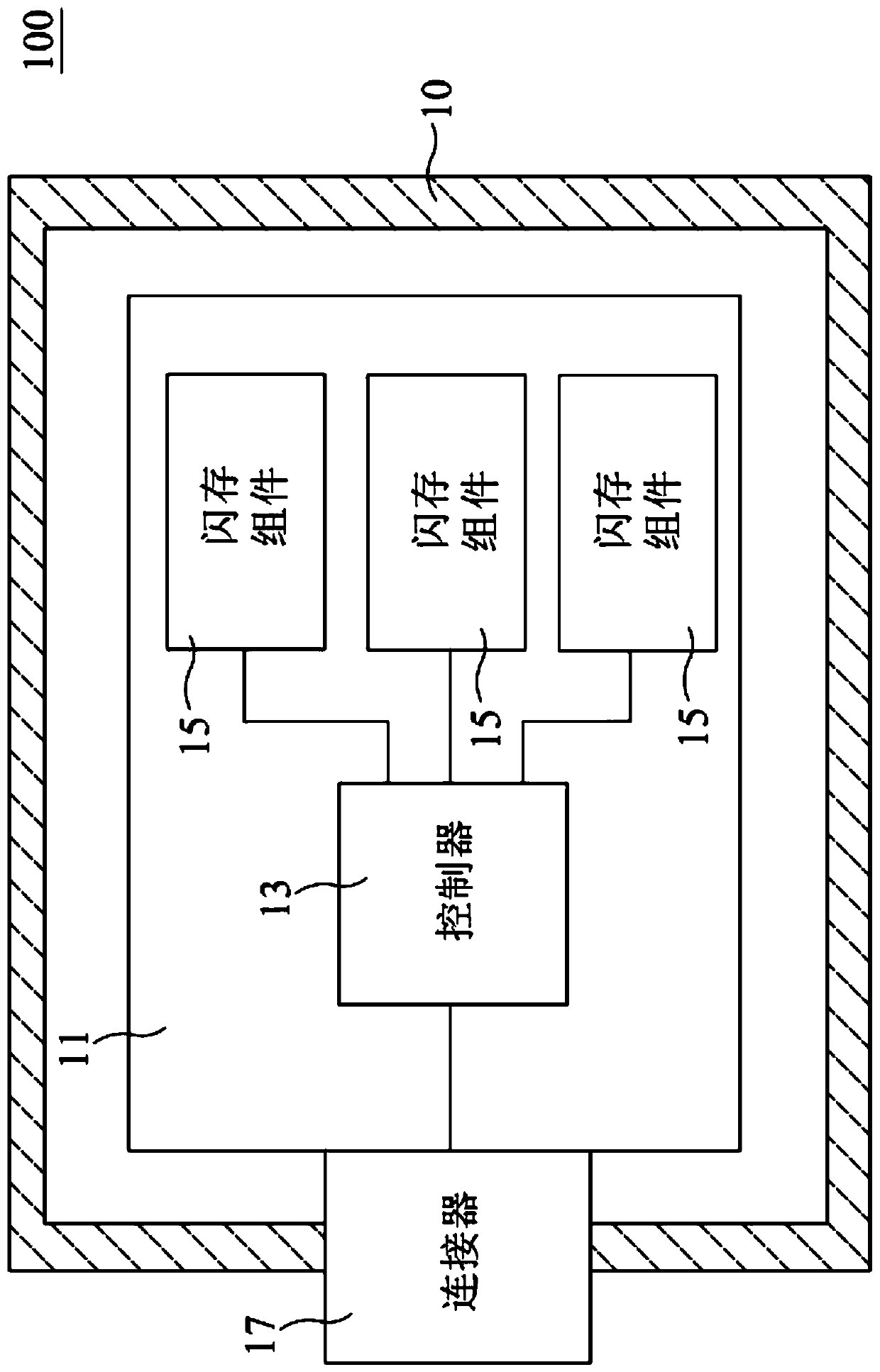

Flame-retardant flash memory device

InactiveCN107437423AAvoid burnsInsulate from high temperatureReducing temperature influence on carrierRecord information storageEngineeringBurn out

The invention provides a flame-retardant flash memory device, which includes a first housing, a first circuit board and a first transmission interface. The first circuit board includes a controller and multiple flash memory assemblies. The first circuit board is arranged in the first housing and is wrapped in a first fireproof material. The first transmission interface is arranged outside the first housing. A circuit connecting wire is connected between the first circuit board and the first transmission interface. The flash memory assemblies are accommodated in the fireproof housing. If the flash memory device is placed in a scene of fire, the fireproof housing can effectively isolate high temperature to prevent the flash memory assemblies from being burnt out.

Owner:INNODISK CORP

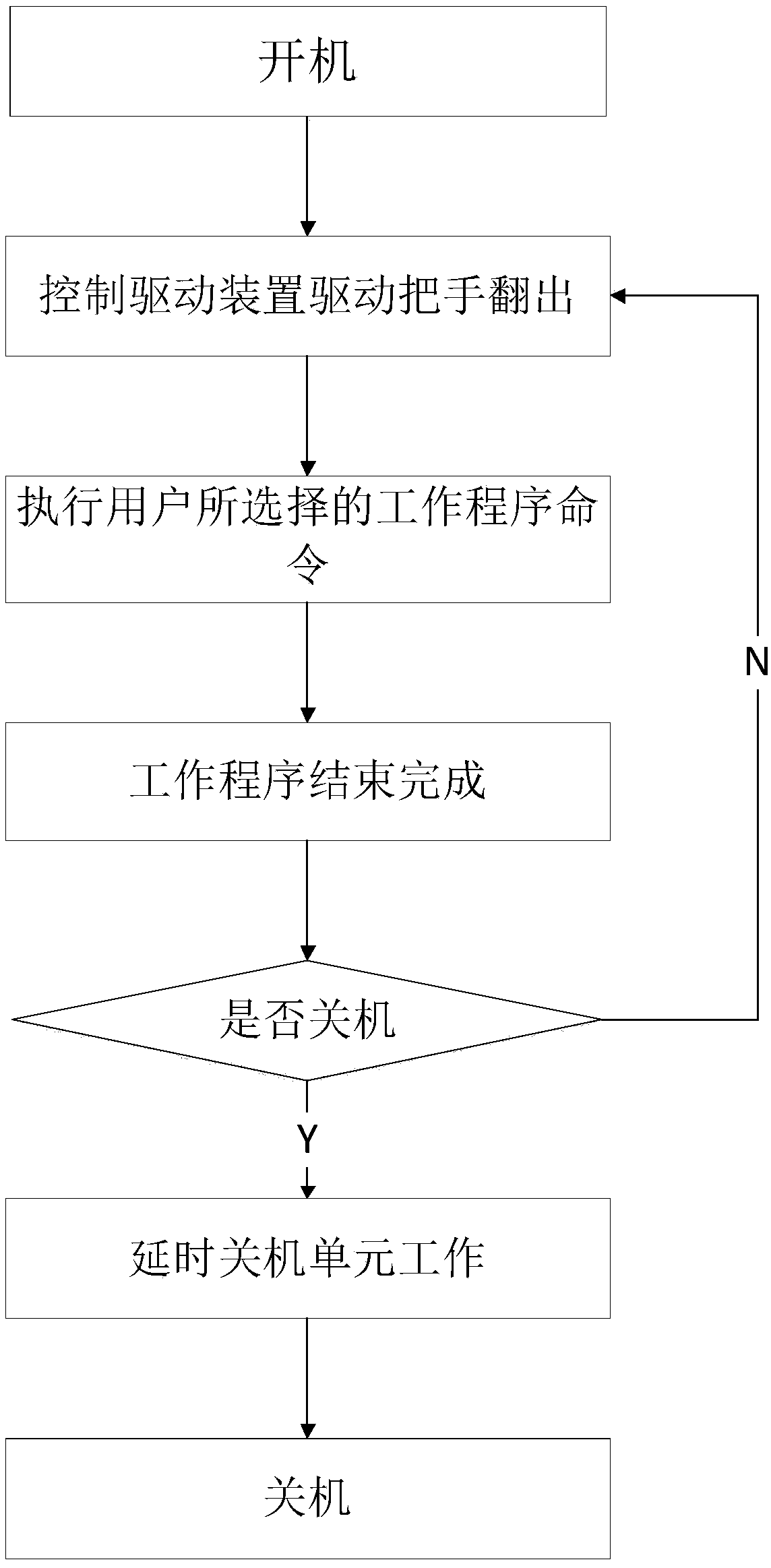

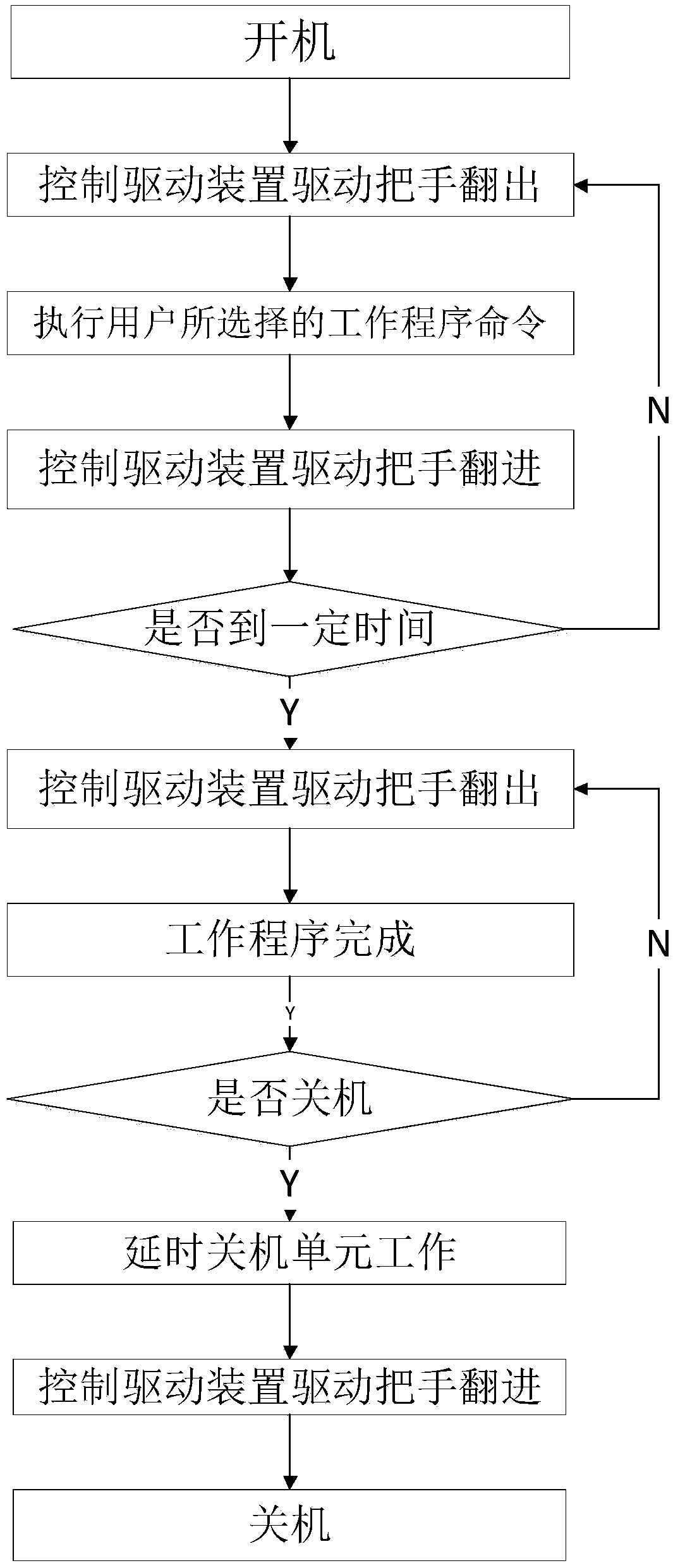

Electric oven with hidden door body and control method of electric oven

PendingCN111035267AEasy to cleanEliminate potential safety hazardsRoasters/grillsRotational axisEngineering

The invention discloses an electric oven with a hidden door body and a control method of the electric oven. The electric oven comprises an electric oven body and a door body with one end rotationallyconnected with the electric oven body. A handle mechanism is arranged on the door body; a containing groove used for containing the handle mechanism is formed in the door body; the handle mechanism isinstalled in the containing groove in a turnover mode through a rotating shaft; and a driving device used for driving the handle mechanism to turn over into / out of the containing groove is installedin the door body; and the electric oven controls the driving device to operate to drive the handle mechanism to turn over into / out of the containing groove. The problems that an existing electric ovenhandle protrudes out of a door body, the occupied space is large, a product is not attractive, the potential safety hazard of personnel collision is likely to be caused, and the door body is not easyto clean are mainly solved.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

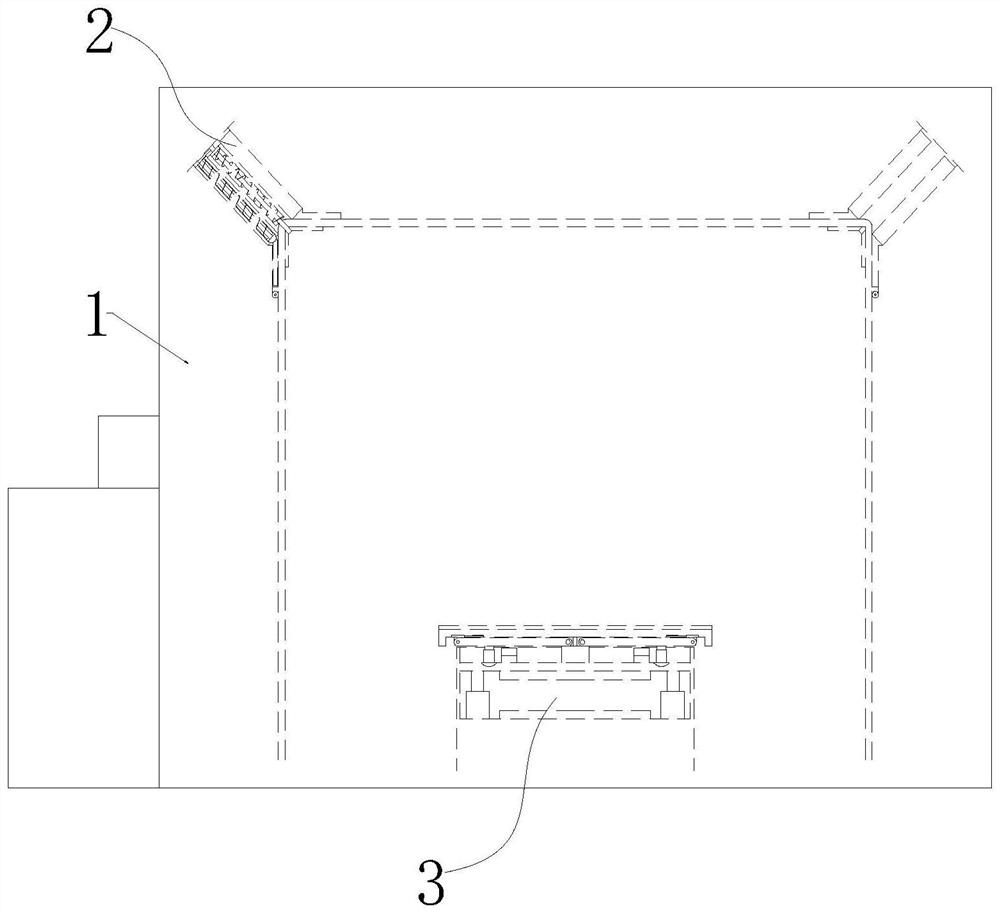

Circulation spray assembly type building structure maintenance device

ActiveCN112497454BMaintain normalReduce water consumptionCeramic shaping apparatusRubber materialStructural engineering

Owner:铭际建筑科技(泰兴)有限公司

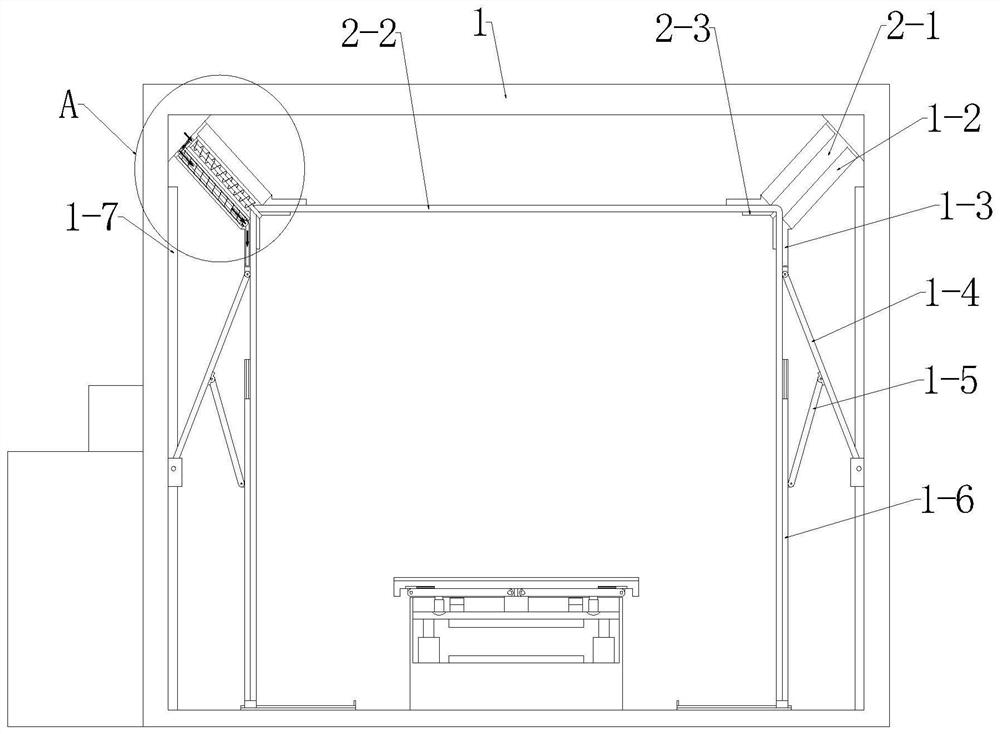

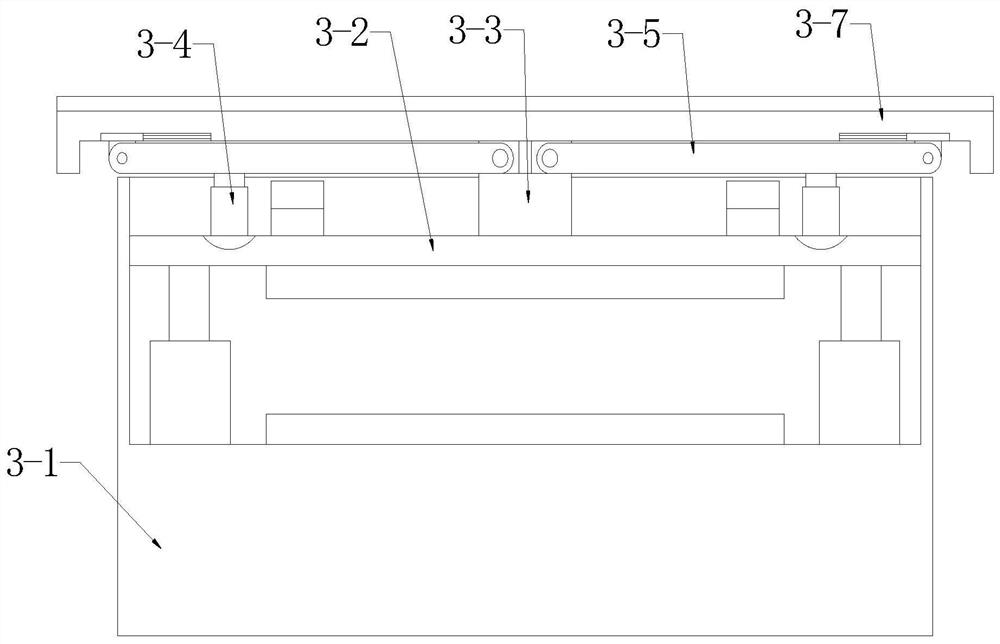

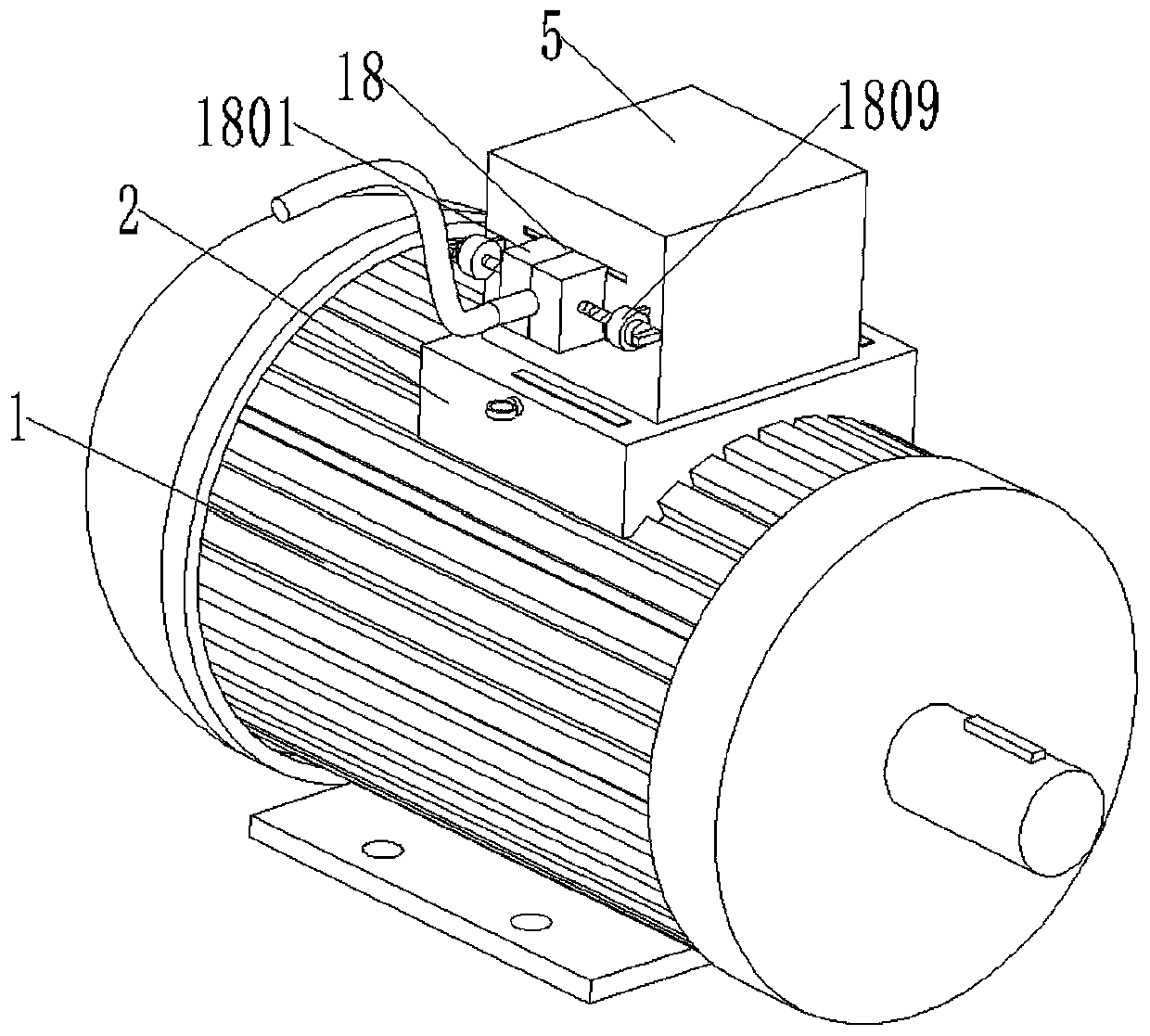

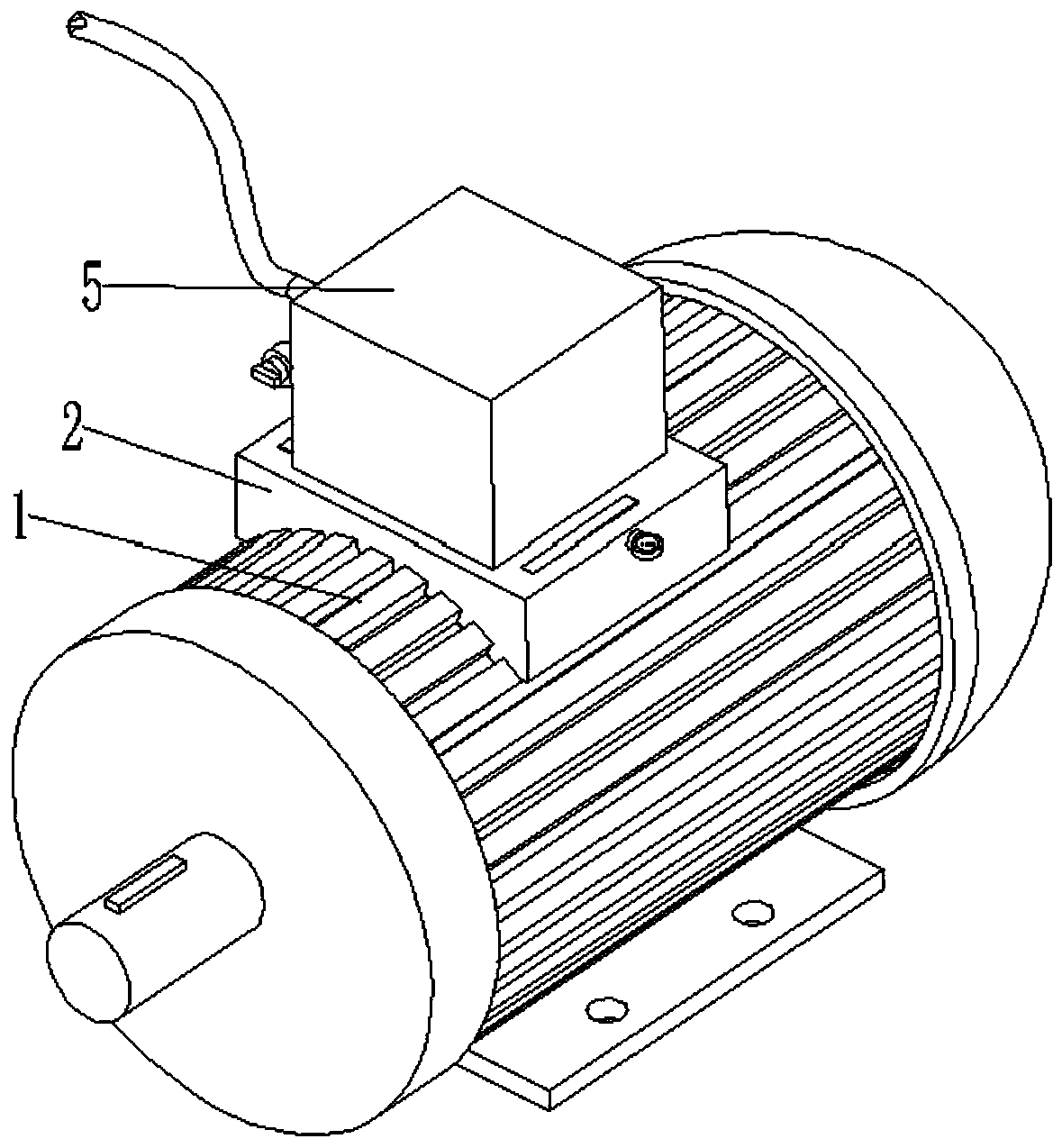

Fireproof motor for high-temperature smog environment

PendingCN111585381AEasy to installGuaranteed uptimeFire rescueSupports/enclosures/casingsElectric machineStructural engineering

The invention discloses a fireproof motor for a high-temperature smog environment. The motor comprises a motor main body, a mounting base, a junction box, a protective cover and a protective structure. According to the invention, the mounting base and the protective cover have a good fireproof function for the junction box of the motor and have a function of isolating high temperature; therefore,the motor can still work normally without being damaged in a high-temperature environment or under a fire condition; normal operation of the motor is guaranteed; the protective cover is very convenient and simple to install; the protective cover is very convenient to disassemble and replace in the later period, and convenience is brought to workers; the arranged protective structure has a good protection effect on the connection part of the motor junction box and the cable, so that the connection part is prevented from being interfered by high temperature and fire, the connection part is not damaged, and normal connection is ensured; and normal operation of the motor is further ensured.

Owner:青岛天一集团红旗电机有限公司

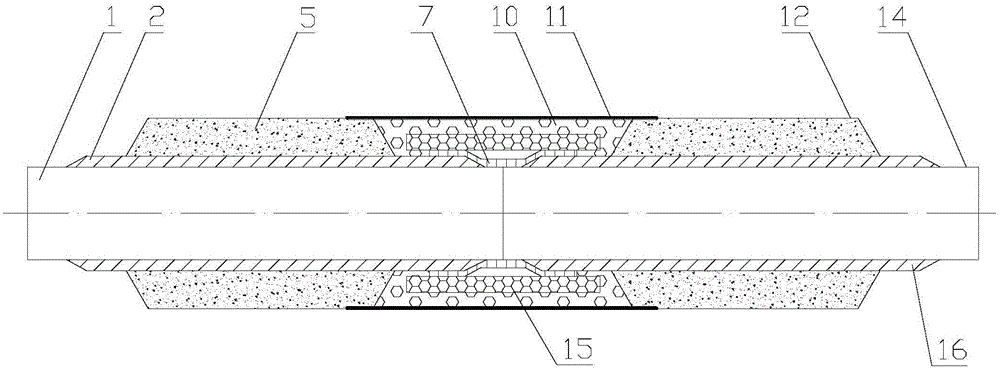

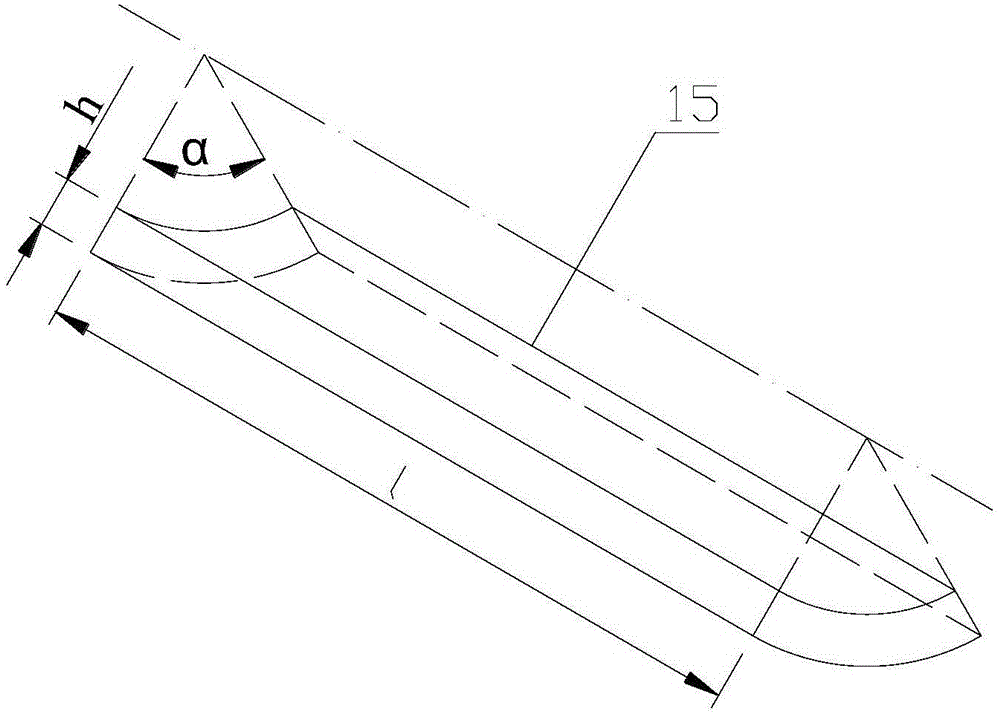

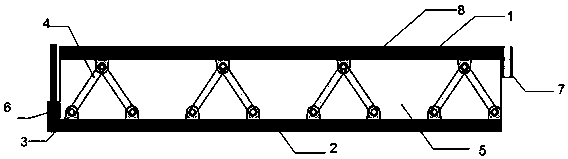

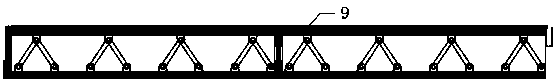

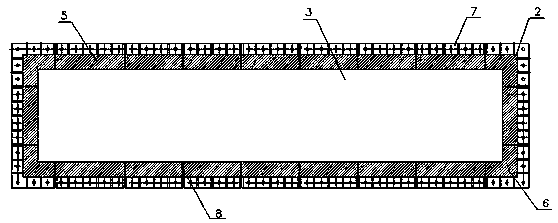

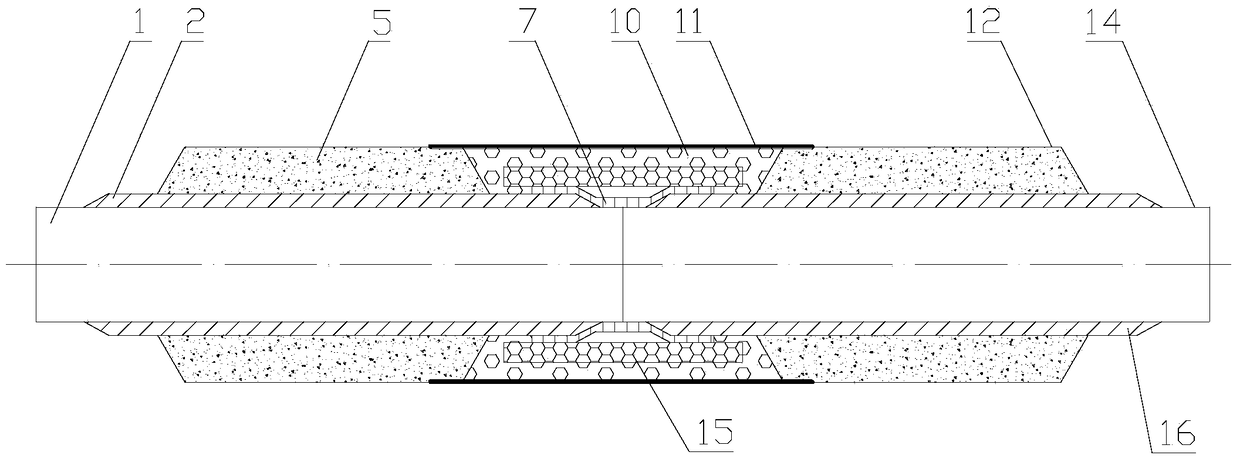

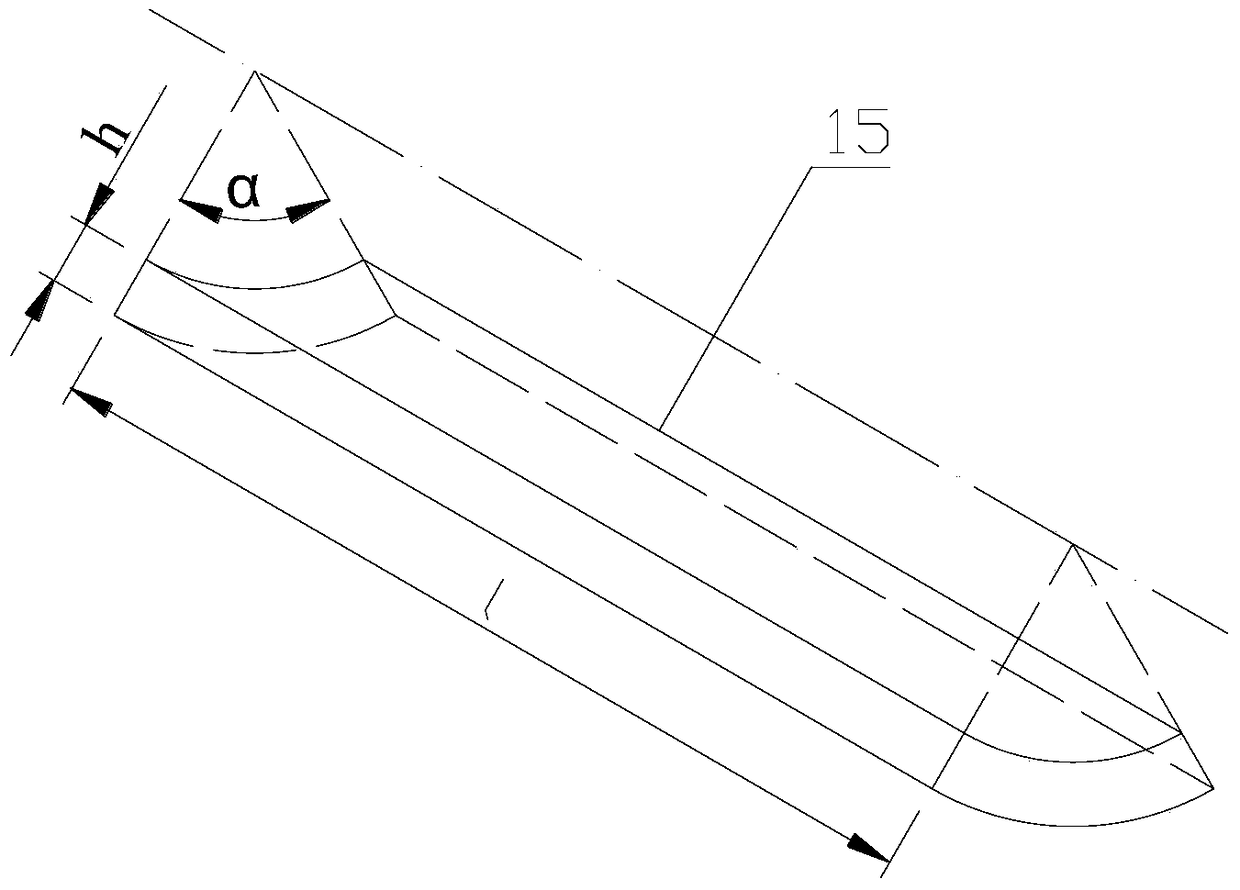

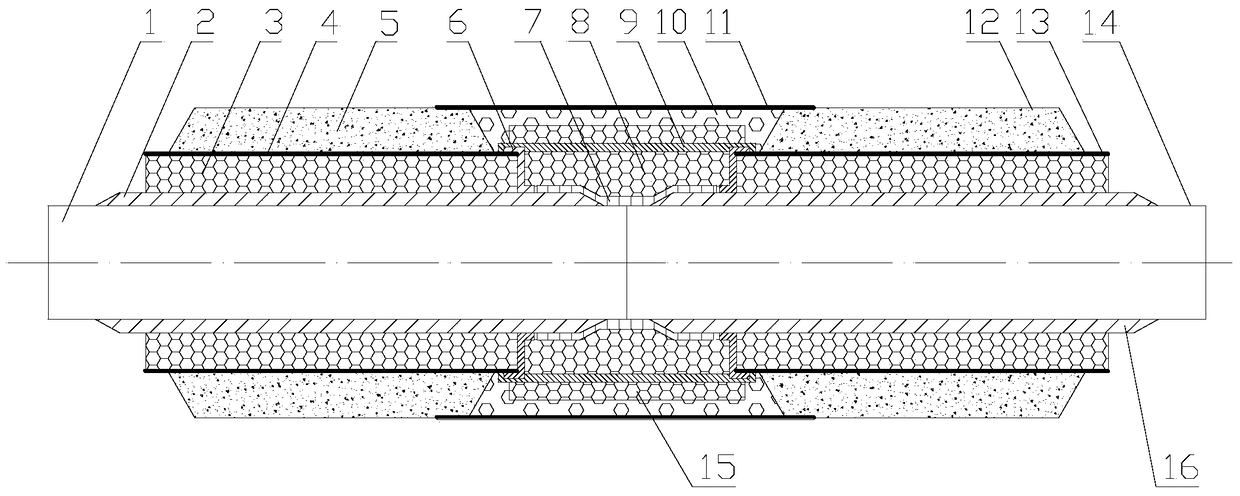

Fast assembly type anti-explosion protective plate for steel bridge main girders and method for manufacturing and assembling fast assembly type anti-explosion protective plate

ActiveCN108560401AReduced dynamic responsePrevent softening and bucklingBridge structural detailsBuilding constructionsShock waveSheet steel

The invention discloses a fast assembly type anti-explosion protective plate for steel bridge main girders and a method for manufacturing and assembling the fast assembly type anti-explosion protective plate. The fast assembly type anti-explosion protective plate comprises a plurality of assembly type anti-explosion protective plate single bodies. The assembly type anti-explosion protective platesingle bodies are combined with one another to form the fast assembly type anti-explosion protective plate, a top steel plate and a bottom steel plate of each assembly type anti-explosion protective plate single body are integrally connected with each other by hinges and energy dissipation soft steel bars, spaces between the top steel plates and the bottom steel plates are filled with foamed aluminum layers, variable-section steel bars are adhered on the bottom steel plates, round steel ingots with holes are adhered on the top steel plates, basalt fiber cloth is adhered on the top steel plates, and SMA (stone mastic asphalt) flame-retardant asphalt concrete abrasion layers are paved on the surfaces of the fast assembly type anti-explosion protective plate after the fast assembly type anti-explosion protective plate is completely assembled. The fast assembly type anti-explosion protective plate and the method have the advantages that the excellent explosion shock wave energy absorptioncapacity of foamed aluminum, the support and energy dissipation capacity of the steel bars, the high-temperature resistance of the basalt fiber cloth and the disguise power and the abrasion resistanceof the SMA flame-retardant asphalt concrete abrasion layers are utilized, and accordingly the purpose of bearing upper load and protecting the steel bridge main girders can be achieved; the cost canbe saved, the quality of the fast assembly type anti-explosion protective plate can be controlled, and the fast assembly type anti-explosion protective plate is convenient to construct.

Owner:SOUTHEAST UNIV

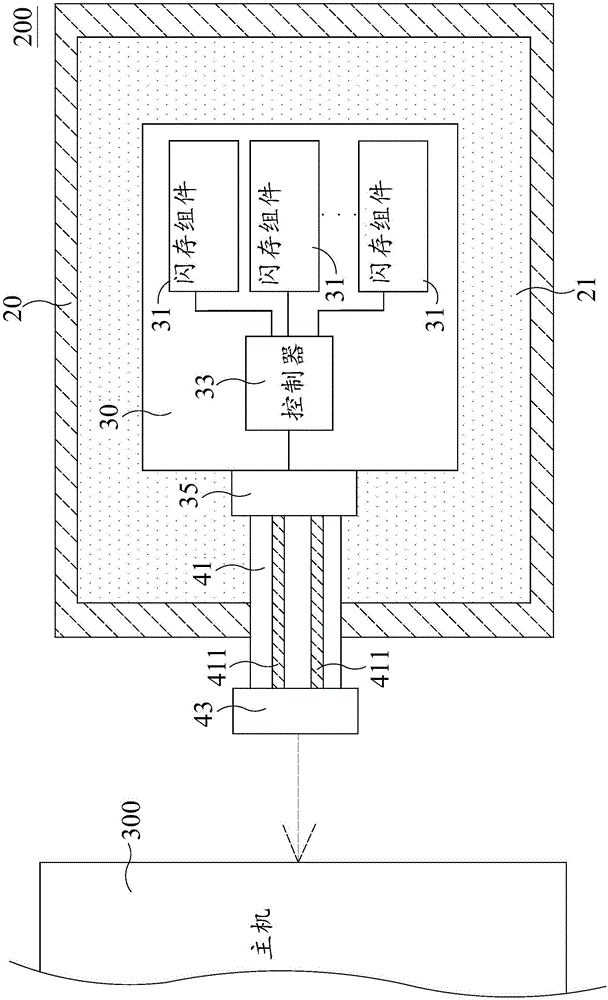

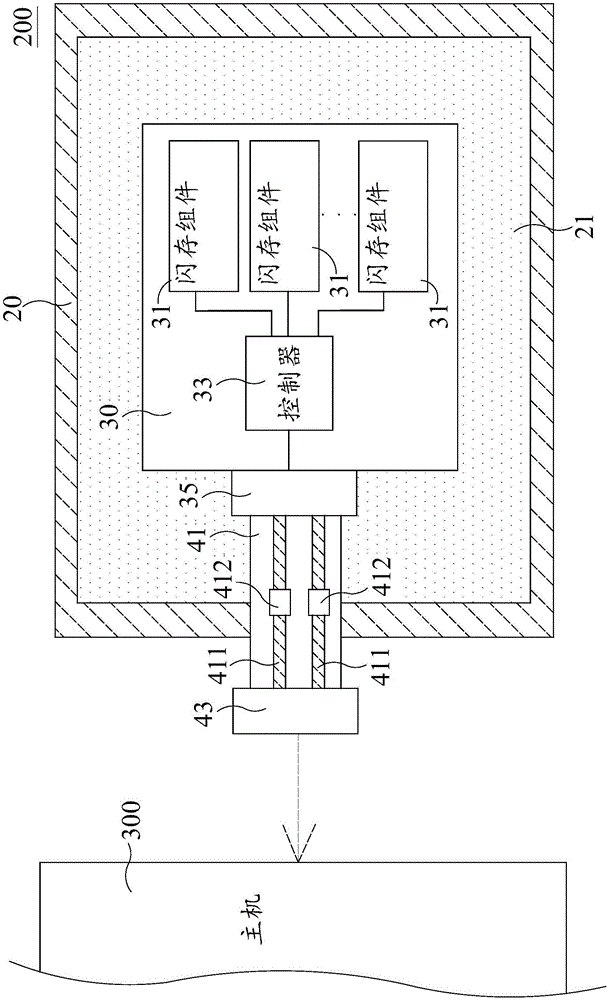

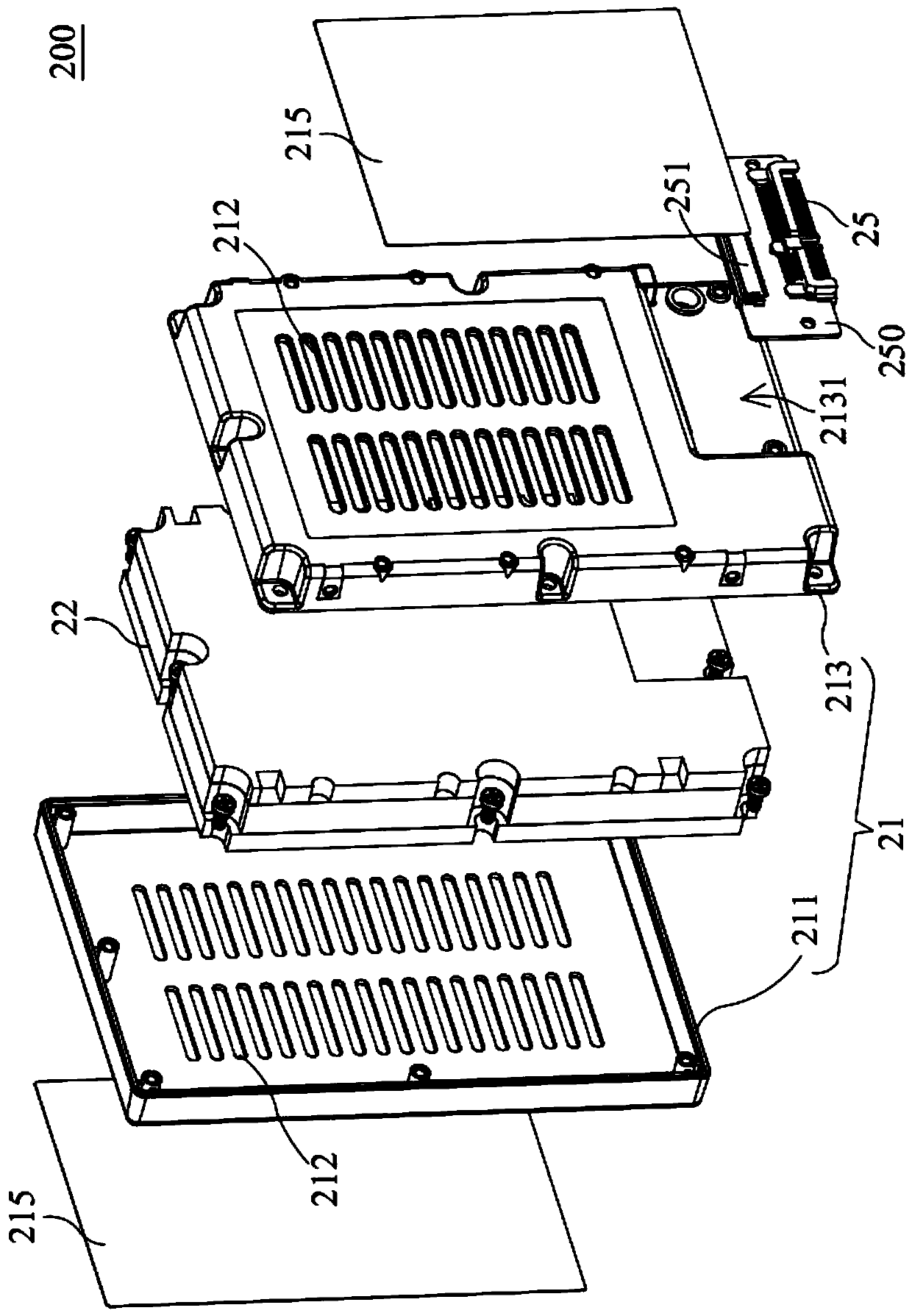

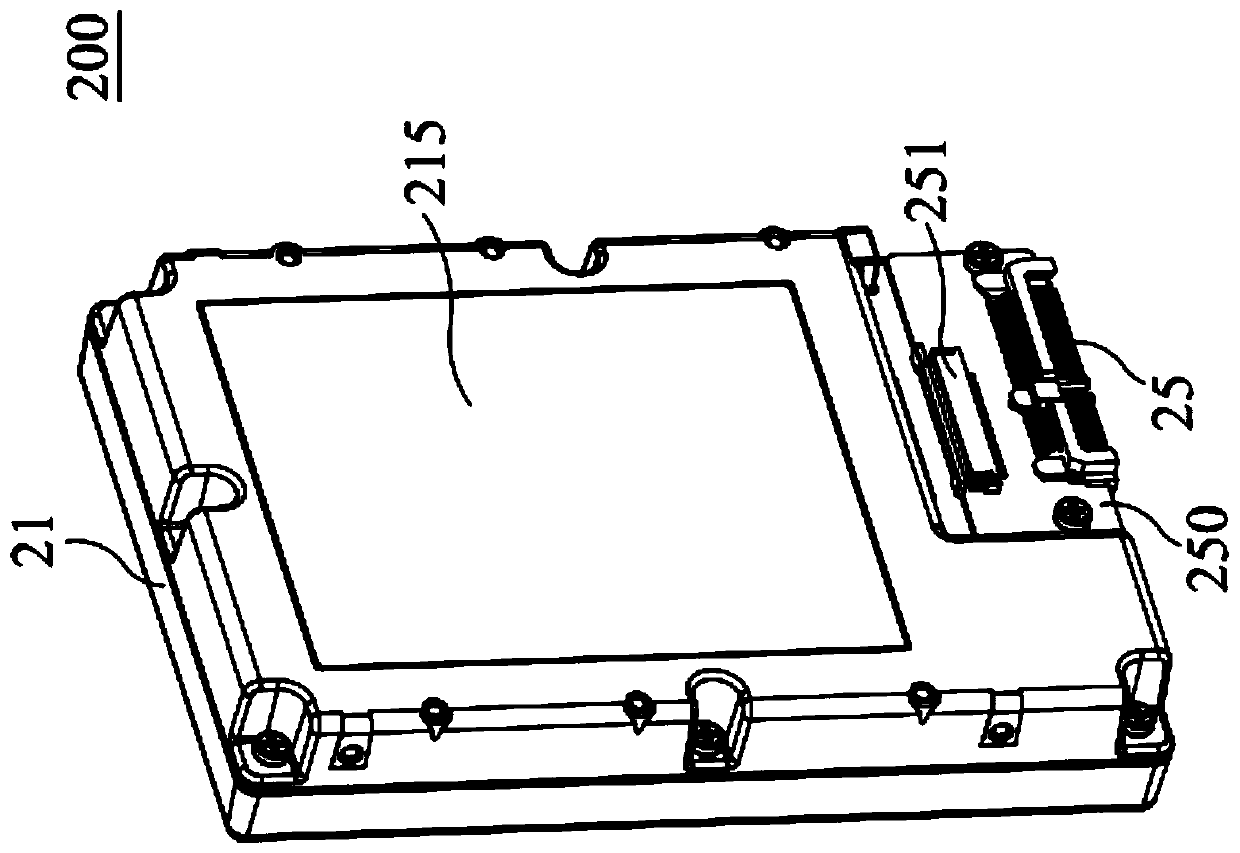

Data storage device with thermal protection

ActiveCN111312300AAvoid burnsAvoid smoldering situationsReducing temperature influence on carrierCarrier constructional parts dispositionEngineeringStructural engineering

The invention provides a data storage device. The data storage device comprises a shell, a main circuit board and an external connector, the shell is provided with a plurality of ventilation openings,the main circuit board comprises a controller and a plurality of flash memory assemblies. The main circuit board is arranged in the shell and is wrapped by a fireproof material; the external connector is arranged outside the shell; a circuit connecting wire is connected between the main circuit board and the external connector; therefore, when the data storage device is located at a fire scene, the main circuit board is coated with the fireproof material so as to prevent the flash memory assembly on the main circuit board from being burnt out, and moreover, the ventilation opening of the shell is utilized, so that the data storage device has better heat dissipation and convection effects, the data storage device can be quickly cooled, and the integrity of data storage is further ensured.

Owner:INNODISK CORP

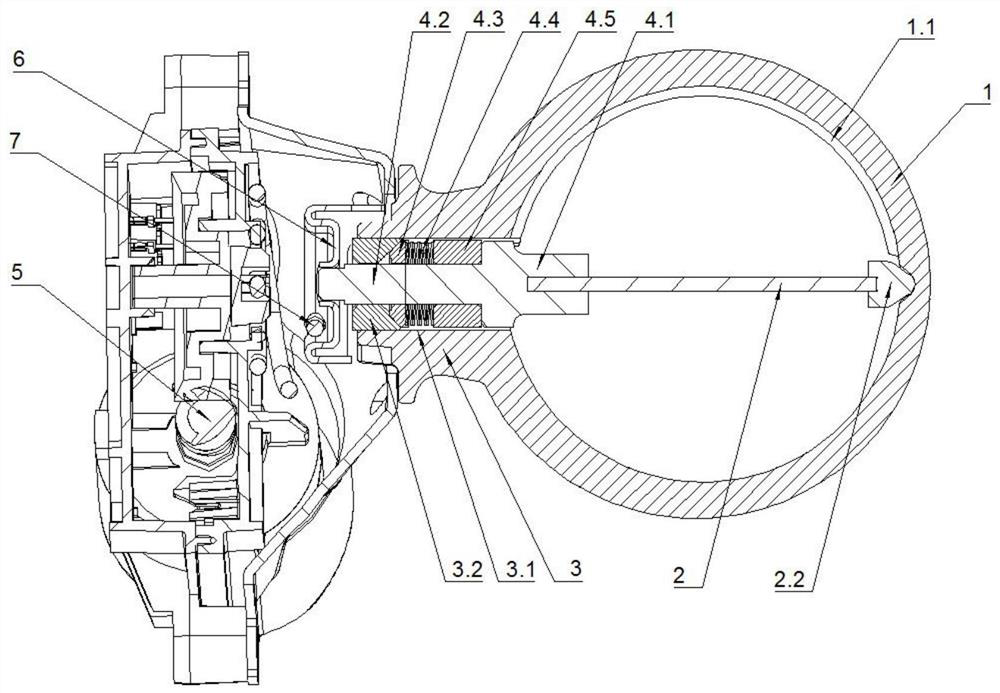

Automobile electronic exhaust active valve structure

PendingCN112833198AInsulate from high temperatureLittle influence of temperatureLift valveValve housingsControl theoryVALVE PORT

The invention discloses an automobile electronic exhaust active valve structure which comprises a valve body, a valve plate, a limiting seat, a main shaft and a power source, wherein an insertion hole is formed in the side face of the valve body, the main shaft is rotationally connected to the insertion hole, the main shaft comprises a first end connected with the valve plate and a second end provided with an elastic adapter, the power source is used for driving the elastic adapter to rotate, the limiting seat is connected to the valve body, and a positioning part used for abutting against the elastic adapter is arranged on the limiting seat. According to the scheme, the opening angle of the valve plate can be controlled by controlling the relative position of the elastic adapter and the limiting seat, the structure is stable, adjustment is convenient, the whole structure cannot be damaged due to the elastic buffering effect between the elastic adapter and the power source, and practicability is higher; and the elastic adapter can also play a role in separation of preventing gas in the valve body from being squeezed into the power source, so that the service life of the overall structure is prolonged.

Owner:宁波经济技术开发区恒阳机械有限公司

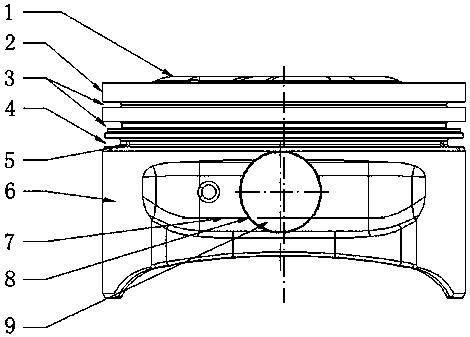

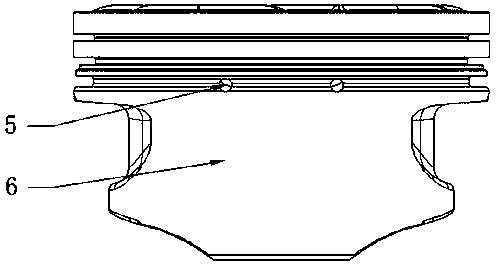

Piston of alcohol fuel internal combustion engine

PendingCN111255592AInsulate from high temperatureAvoid ablationMachines/enginesPistonsAlcohol fuelGasoline

The invention relates to a piston of an alcohol fuel internal combustion engine. At present, conventional gasoline engine pistons are corroded by alcohol fuel and combustion products thereof in the alcohol internal combustion engine, meanwhile, the compression ratio of the alcohol internal combustion engine is high, the burst pressure is large, the instantaneous temperature is high, the top of thegasoline engine piston and the head of a piston are easy to ablate at high temperature, and the heat isolation and heat resistance are poor. The piston of the alcohol fuel internal combustion enginecomprises a piston top (1), a piston head (2), a piston skirt (6) and a piston pin seat (8), wherein the piston top is a forming top, the section of the protruding portion is approximately in an ovaloid shape, and the remaining part of the piston top is of a flat top structure; the piston top is provided with a valve avoiding pit; the piston head is mainly composed of a rectangular fire bank, twogas ring annular grooves (3) and an oil ring annular groove (4); the two air ring annular grooves are filled with air rings for sealing and heat conduction; and the oil ring annular groove is placed into a combined oil ring for oil scraping, oil distribution and gas sealing assistance. The piston is applied to the alcohol fuel internal combustion engine.

Owner:营口福泰科技有限责任公司

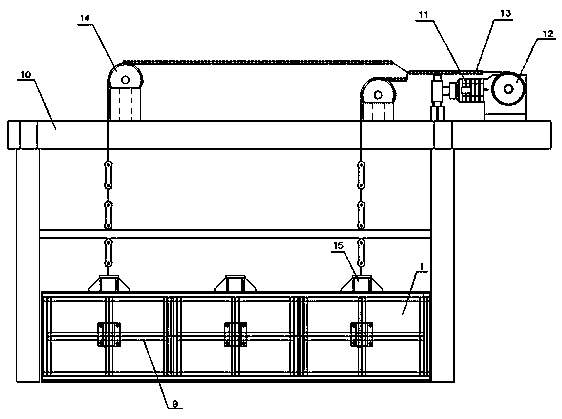

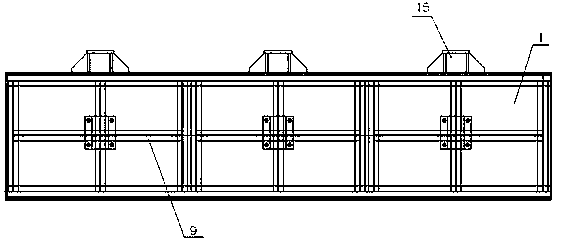

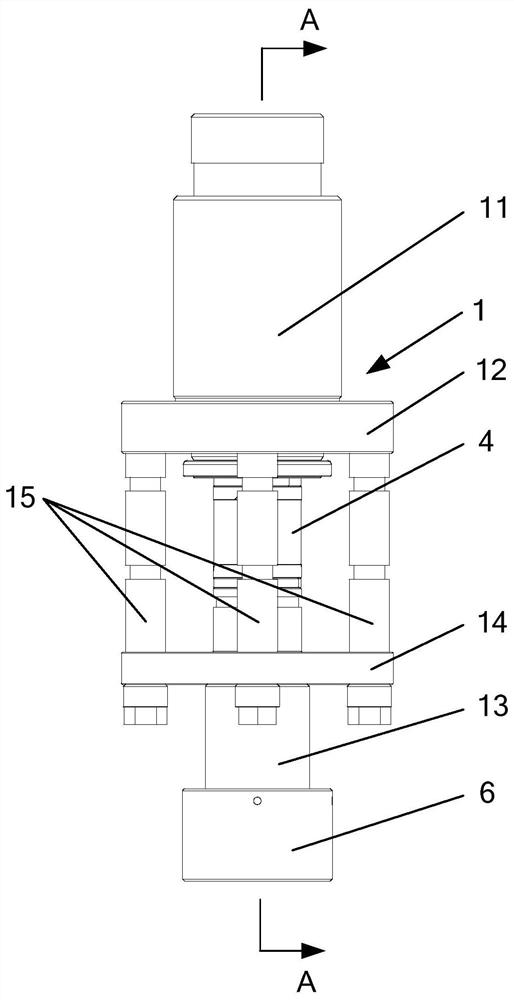

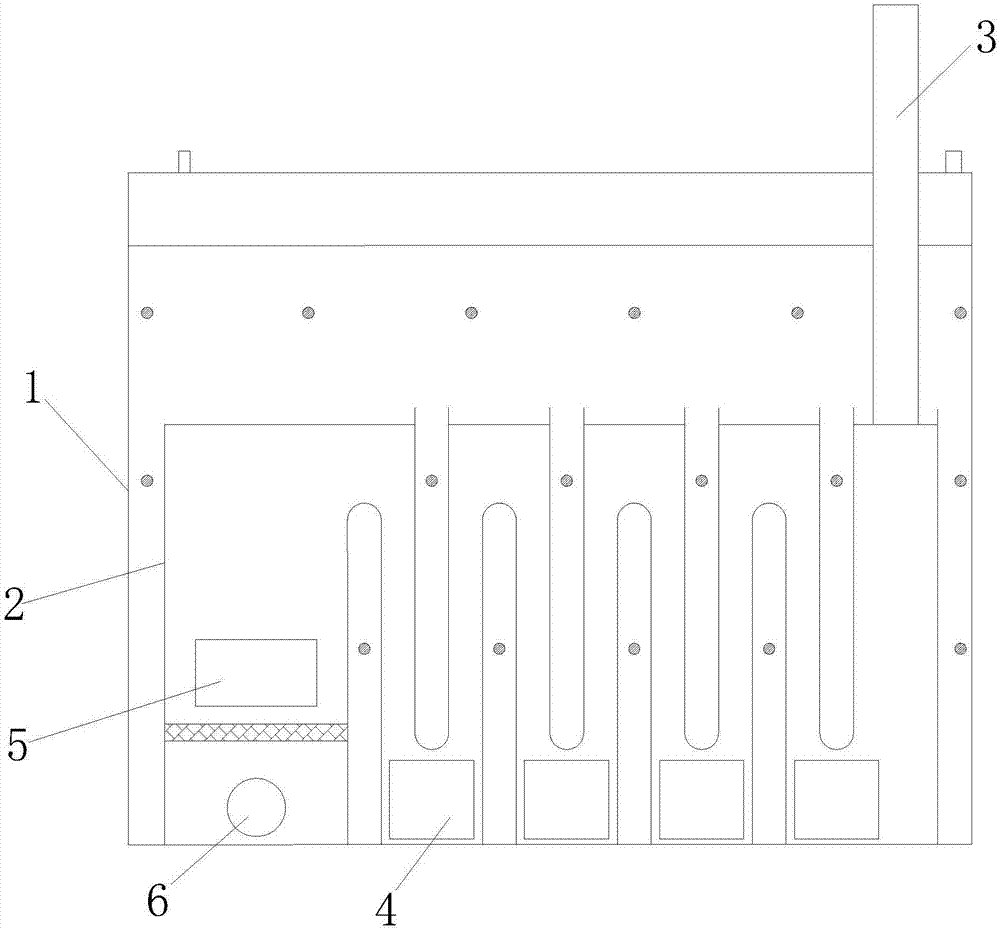

Thermal treatment furnace fire door without water cooling

PendingCN109628724AGuaranteed service lifeLow costFurnace typesHeat treatment furnacesCast ironEngineering

The invention discloses a thermal treatment furnace fire door without water cooling, and relates to the technical field of thermal treatment equipment. The thermal treatment furnace fire door withoutwater cooling comprises a fire door frame. The fire door frame comprises a fire door base plate. A fire door casting is arranged on the inward side of the fire door base plate. The fire door casting comprises a plurality of first castings and four second castings, wherein the section of each first casting is rectangular, and the section of each second casting is in the shape of an L. the first castings and the second castings are connected in sequence to define a rectangle, the second castings are located in the four corners of the rectangle, a cavity is formed in the middle of the rectangle,and the cavity is filled with refractory fibers. A plurality of pieces of heat-resisting cast iron are further arranged on the inward side of the fire door base plate and are evenly arranged outside the fire door casting, and the side, facing the fire door castings, of each piece of heat-resisting cast iron is attached to the corresponding fire door casting. According to the thermal treatment furnace fire door without water cooling, the fire door is cooled without adopting a water cooling manner, the phenomenon that a fire door is prone to being corroded because of water cooling temperature lowering is completely avoided, and the service life of the fire door is guaranteed.

Owner:NANJING IRON & STEEL CO LTD

A quick-assembled steel bridge main beam anti-explosion protective plate and its production and assembly method

ActiveCN108560401BReduced dynamic responsePrevent softening and bucklingBridge structural detailsBuilding constructionsIngotBasalt fiber

The invention discloses a fast assembly type anti-explosion protective plate for steel bridge main girders and a method for manufacturing and assembling the fast assembly type anti-explosion protective plate. The fast assembly type anti-explosion protective plate comprises a plurality of assembly type anti-explosion protective plate single bodies. The assembly type anti-explosion protective platesingle bodies are combined with one another to form the fast assembly type anti-explosion protective plate, a top steel plate and a bottom steel plate of each assembly type anti-explosion protective plate single body are integrally connected with each other by hinges and energy dissipation soft steel bars, spaces between the top steel plates and the bottom steel plates are filled with foamed aluminum layers, variable-section steel bars are adhered on the bottom steel plates, round steel ingots with holes are adhered on the top steel plates, basalt fiber cloth is adhered on the top steel plates, and SMA (stone mastic asphalt) flame-retardant asphalt concrete abrasion layers are paved on the surfaces of the fast assembly type anti-explosion protective plate after the fast assembly type anti-explosion protective plate is completely assembled. The fast assembly type anti-explosion protective plate and the method have the advantages that the excellent explosion shock wave energy absorptioncapacity of foamed aluminum, the support and energy dissipation capacity of the steel bars, the high-temperature resistance of the basalt fiber cloth and the disguise power and the abrasion resistanceof the SMA flame-retardant asphalt concrete abrasion layers are utilized, and accordingly the purpose of bearing upper load and protecting the steel bridge main girders can be achieved; the cost canbe saved, the quality of the fast assembly type anti-explosion protective plate can be controlled, and the fast assembly type anti-explosion protective plate is convenient to construct.

Owner:SOUTHEAST UNIV

High-temperature-resistant valve rod for steam turbine

PendingCN113374541AAvoid high temperature effectsExtend your lifeValve arrangementsMachines/enginesStructural engineeringSteam turbine

The invention discloses a high-temperature-resistant valve rod for a steam turbine. The high-temperature-resistant valve rod comprises a rod body, a high-temperature-resistant unit is arranged outside the rod body, and the high-temperature-resistant unit is connected with the rod body through a detachable unit. According to the high-temperature-resistant valve rod, fitting and protection of a rod plugging body are achieved by arranging a protection plate, the high-temperature resistance of the valve rod is improved by arranging an inner high-temperature spraying layer on the protection plate, detachable connection of the protection plate and the rod body is achieved by arranging a sliding block and a sliding groove, replacement of the protection plate is facilitated, the maintenance efficiency is improved, by arranging a first boss and a second boss, a perfect overlap between two adjacent protection plates is achieved, and the outer circular surface of the rod body can be fully covered. The high-temperature-resistant valve rod solves the problem that after a spraying layer of an existing valve rod falls off, the valve rod needs to be cleaned up and sprayed again, and using is quite inconvenient.

Owner:HUANENG POWER INT CO LTD DEZHOU POWER PLANT

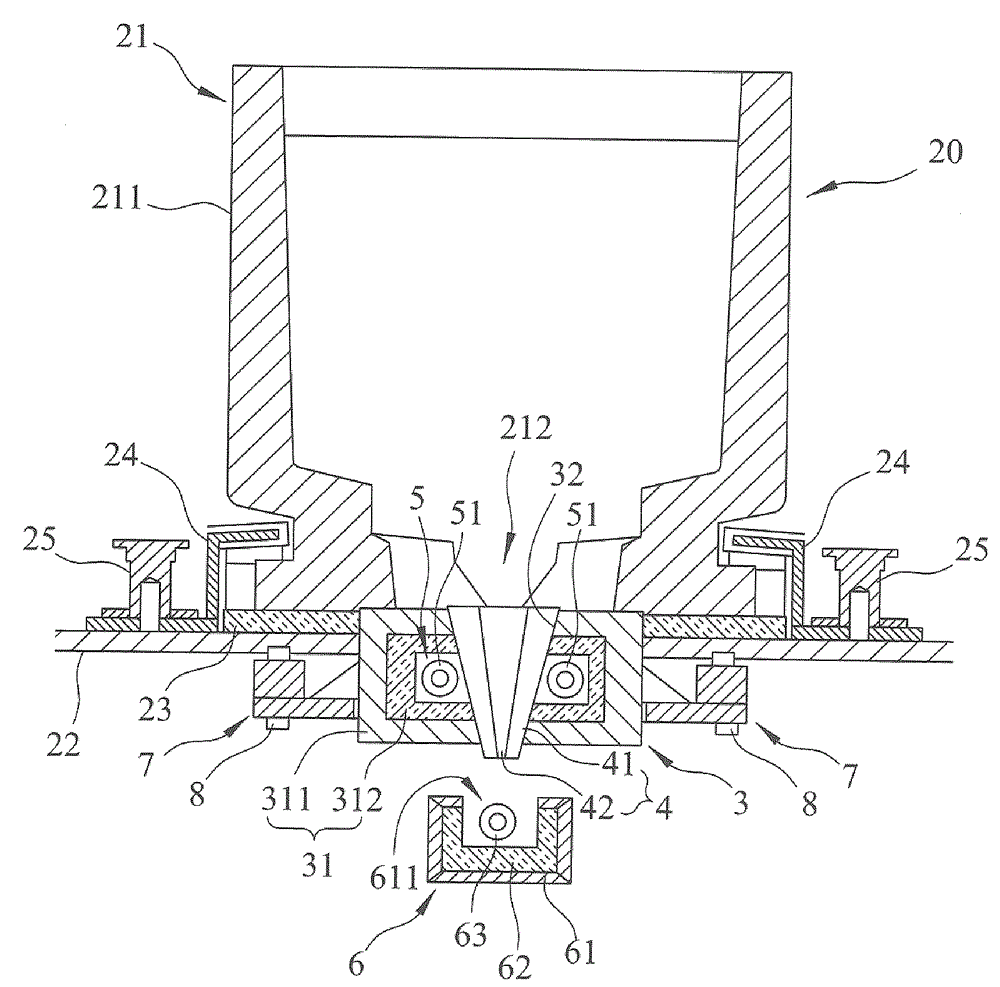

Carrier device and method for wave soldering of light bulb components

The invention discloses a carrier device and method for wave soldering of bulb components, and relates to the technical field of bulb component welding. The carrier device includes a bottom plate, a cover plate and a frame, the frame is fixedly connected to the bottom plate, the frame surrounds the bottom plate, and a plurality of welding holes for welding the bulb assembly are opened on the bottom plate, the shape of the welding hole matches the light bulb assembly, and the frame A snap ring assembly is arranged on the top, and the cover plate is covered on the bottom plate through the snap ring assembly. The method includes the following steps: S1, putting the contact piece and the PCB board into a plastic seat to form a light bulb assembly; S2, putting the light bulb assembly into the welding hole on the bottom plate, covering the cover plate, and pressing the cover plate tightly through the clamp spring assembly ; S3, placing the carrier device on the conveyor belt, and transferring the carrier device to the wave soldering machine for automatic wave soldering. The invention adopts the carrier device to carry out wave soldering on the light bulb assembly, which can improve the welding quality, has a high welding yield, and thus improves the welding efficiency.

Owner:湖北兆元科技有限公司

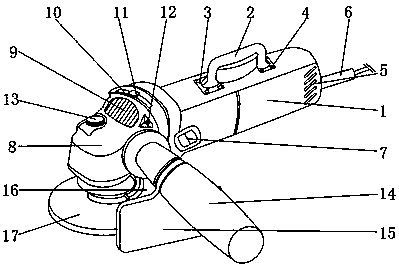

Surface grinding device for processing hardware equipment

InactiveCN109202641AInsulate from high temperatureAvoid affecting workPortable grinding machinesGrinding/polishing safety devicesSurface grindingEngineering

The invention discloses a surface grinding device for processing hardware equipment. The surface grinding device comprises a device body; the upper end of the device body is provided with a convenienthandle, the convenient handle is C-shaped, and each of two ends of the convenient handle has a connecting seat; the convenient handle is fixedly mounted on the device body by connecting seats at bothends and installation screws; a power cord is fixedly connected to the tail end of the device body; a start switch is arranged on one side of the front end of the device body; the front end of the device body is fixedly connected with a head assembly; and an air inlet is formed in an upper inclined surface of the head assembly. The surface grinding device for processing hardware equipment includes the convenient handle, a protective baffle and a detachable dustproof net, which can avoid the situation that hands is burned when the hands directly holds the device body due to high temperature ofthe device body, and the use is affected; the device can effectively protect the left hand when the auxiliary handle is used so as to avoid being cut by large particles splashed, can effectively absorb the dust in the air intake, avoid burning the motor, and is convenient to remove and replace at any time.

Owner:长兴曼尔申机械科技有限公司

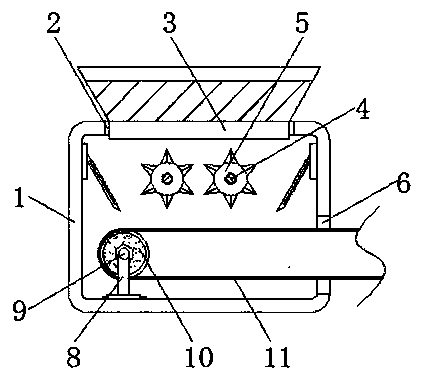

Medical waste incineration device with crushing effect

InactiveCN108709189AAvoid waste accumulationConducive to incinerationIncinerator apparatusGrain treatmentsEngineeringMedical treatment

The invention relates to the technical field of energy conservation and environmental protection, and discloses a medical waste incineration device with a crushing effect. The medical waste incineration device comprises a feeding chamber, wherein a feeding hole is formed in the top of the feeding chamber, a feeding hopper penetrates through the top of the feeding chamber, transmission shafts penetrate through the back surface of the feeding chamber, and roller wheels sleeve the ends, located in a cavity of the feeding chamber, of the transmission shafts; a through hole is formed in the right side of the feeding chamber, a material barrel is fixedly installed on the right side of the feeding chamber, a supporting rod is fixedly installed on the inner bottom wall of the cavity of the feedingchamber, and a motor is fixedly installed on the back surface of the end, far away from the inner bottom wall of the cavity of the feeding chamber, of the supporting rod; and a rotating disc sleevesan output shaft of the motor, a conveying belt with one end extending into the cavity of the material barrel sleeves the rotating disc, and the end, far away from the feeding chamber, of the materialbarrel communicates with a conveying barrel. According to the medical waste incineration device with the crushing effect, the crushing effect is good, incineration is more sufficient, and use by people is facilitated.

Owner:ZAOZHUANG UNIV

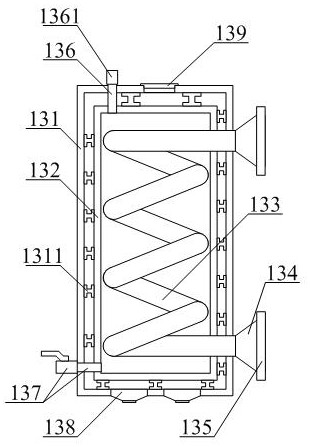

Capsule door of rescue capsule used for mine

ActiveCN102383704BReduce cooling costsGood heat insulationFireproof doorsConstruction fastening devicesLocking mechanismElectrical and Electronics engineering

The invention discloses a capsule door of a rescue capsule used for a mine, belongs to the technical field of capsule doors of rescue capsules and aims at providing a capsule door of a rescue capsule for a mine, wherein the capsule door is provided with a thermal insulating layer and has a good sealing effect. The technical scheme adopted by the invention is as follows: the capsule door of the rescue capsule used for the mine comprises a door frame, a door, hinges, a sealing strip, a thermal insulating material and an observation window, wherein the door is connected to the door frame by virtue of the two hinges; one circle of sealing strip is arranged between the door frame and the door; and the door is provided with the observation window. The capsule door is structurally characterized in that one circle of flitch is fixed on a door plank; a stainless steel trim plate is fixed on the flitch; the thermal insulating material is installed in a sealed space among the door plank, the flitch and the stainless steel trim plate; and the door is provided with a locking mechanism which can press the door onto the door frame. The capsule door can be applied to the rescue capsule under the mine.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

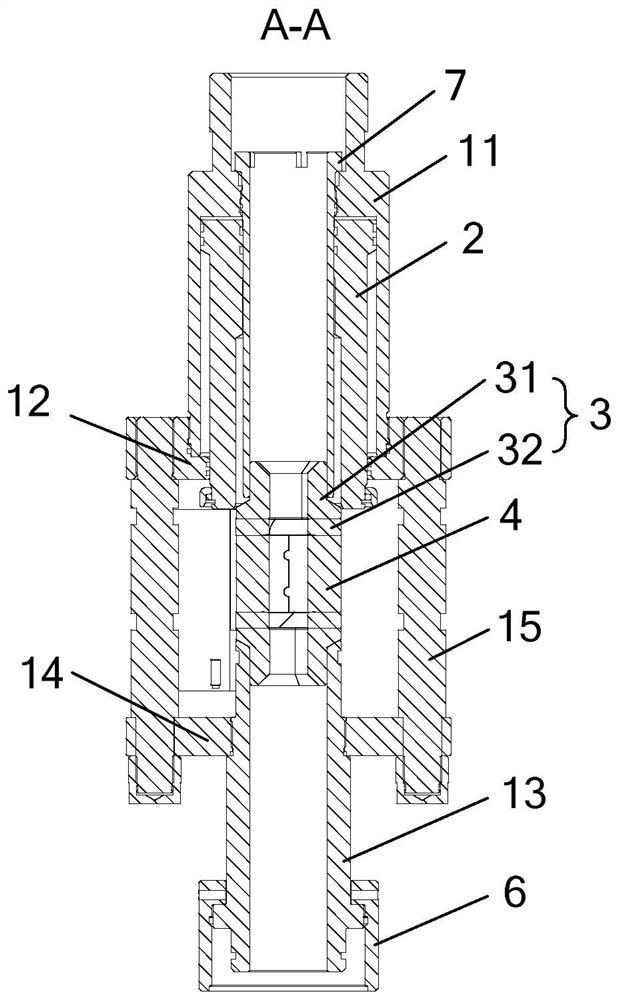

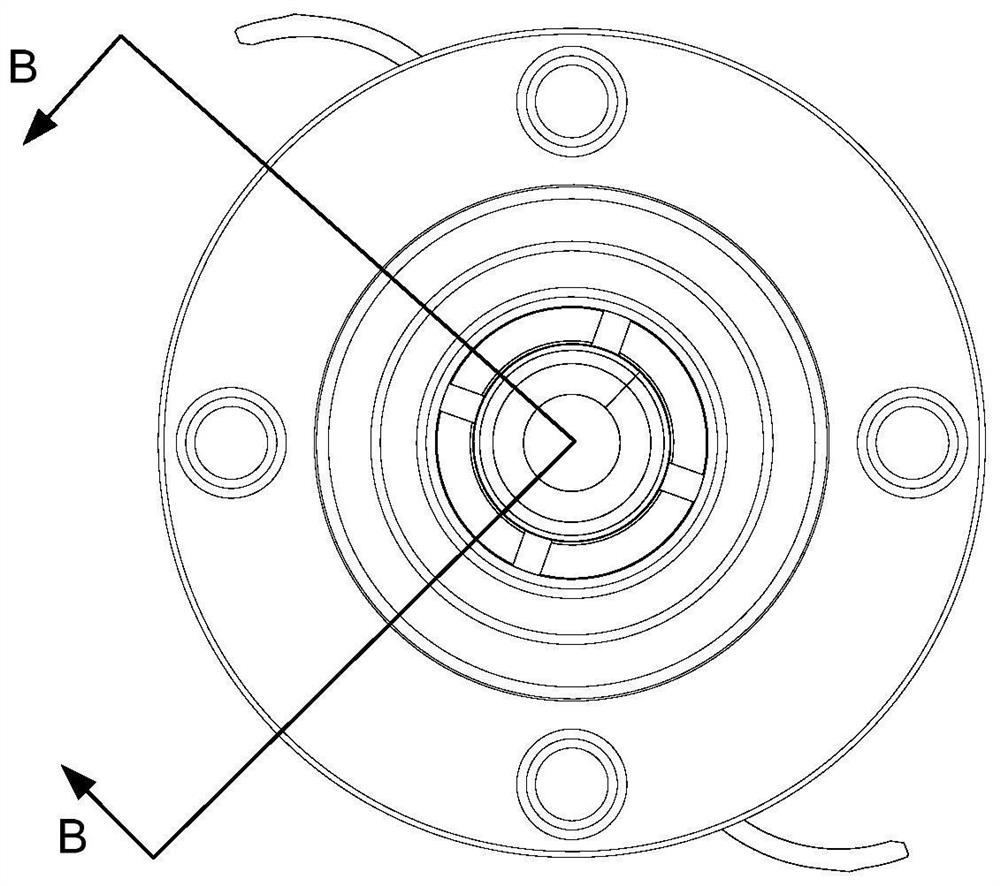

High-temperature-resistant heat-insulation blowout preventer

The invention discloses a high-temperature-resistant heat-insulation blowout preventer. The high-temperature-resistant heat-insulation blowout preventer comprises a tubular column base body, a cylinder sleeve, a pressing piece, a rubber core and a cooling device; the cylinder sleeve, the pressing piece and the rubber core are all installed in the tubular column base body, and a hydraulic control channel of the cylinder sleeve is located above the rubber core; the cylinder sleeve can move in the tubular column base body in the axial direction and abut against the pressing piece, so that the rubber core is pressed and sealed by the pressing piece; a containing cavity is formed in the abutting end of the cylinder sleeve, and when the cylinder sleeve abuts against the pressing piece, the pressing piece and the rubber core are located in the containing cavity; and the cooling device is used for cooling the rubber core. The high-temperature-resistant heat-insulation blowout preventer can reliably work under the high-temperature condition, and normal operation of well control equipment is guaranteed.

Owner:CHINA OILFIELD SERVICES

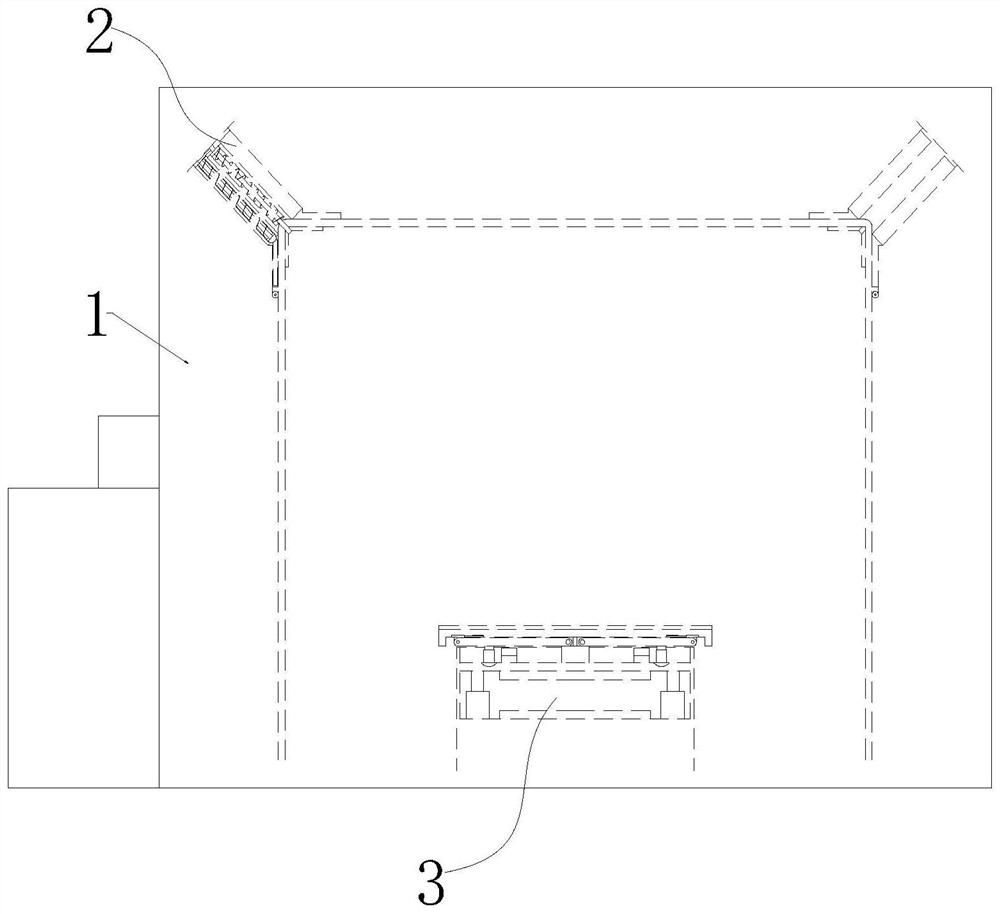

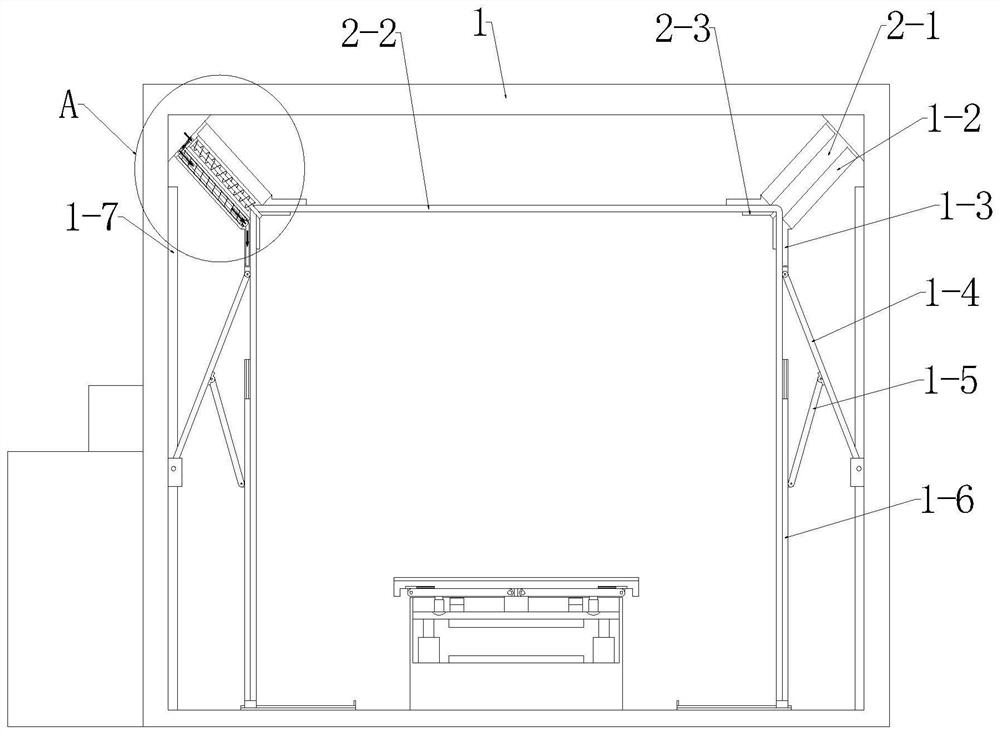

Circulating spraying assembly type building structure maintenance device

ActiveCN112497454AMaintain normalReduce water consumptionCeramic shaping apparatusRubber materialStructural engineering

The invention discloses a circulation spraying assembly type building structure maintenance device which comprises a shell, a spraying mechanism and a vibration reduction mechanism, the spraying mechanism and the vibration reduction mechanism are arranged in the shell from top to bottom, the spraying mechanism sprays building components, and the spraying mechanism enables the maintenance range ofa building structure to be narrowed. The vibration reduction mechanism buffers vibration of the building structure and controls the buffer strength through the resistance magnitude. The spraying mechanism forms a maintenance bin on the outer side of the building structure through a maintenance layer made of a rubber material and sprays water mist into the maintenance bin, so that the water mist diffuses into the maintenance bin under the driving of airflow generated during spraying, thus the water mist is in comprehensive contact with the building structure, the building structure is maintained through the water mist, the water consumption can be reduced, and the building structure can be comprehensively maintained.

Owner:铭际建筑科技(泰兴)有限公司

A compound joint structure of counterweight layer for large-diameter submarine pipeline

ActiveCN105156831BAvoid the problem of incomplete mold fillingShorten the ripening timePipe elementsHigh densityMouth repair

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

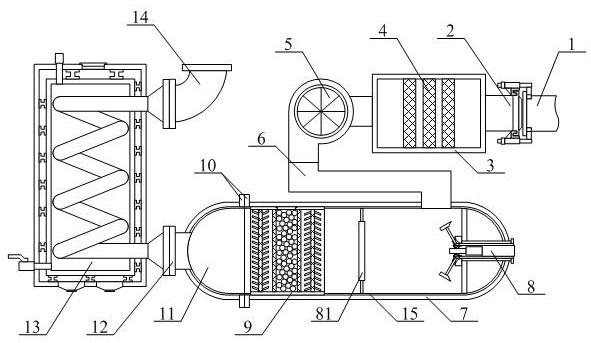

Energy-saving and environment-friendly heat accumulating type waste gas incinerator

InactiveCN111895429AEasy to disassembleAvoid pollutionDispersed particle filtrationTransportation and packagingCombustorFlue gas

The invention provides an energy-saving and environment-friendly heat accumulating type waste gas incinerator. The energy-saving and environment-friendly heat accumulating type waste gas incinerator comprises a waste gas generation equipment gas outlet pipe, a pipeline clamping frame structure, a filtering box, a main filtering net, a draught fan, a waste gas conveying pipe, an incinerator body, aspray head uninstalling frame structure, a flue gas filtering frame structure, an installing flange plate, an incinerator cover, an end part connecting flange, a reinforced heat storage box structure, a chimney connecting pipe and a heat insulation pad, wherein the pipeline clamping frame structure is clamped on the left side of the waste gas generation equipment gas outlet pipe, the filtering box is welded on the left side of the pipeline clamping frame structure, and the main filtering net is in bolted connection with the inner side of the filtering box. The energy-saving and environment-friendly heat accumulating type waste gas incinerator has the beneficial effects that through arrangement of a fixed pipe, a movable pipe, a guide plate, a lug plate, a connecting rod, a sealing plate and a spring gasket, a burner nozzle can be uninstalled easily, and meanwhile waste gas on the inner side of the incinerator body after uninstalling is prevented from leaking out to pollute the air environment.

Owner:张宝通

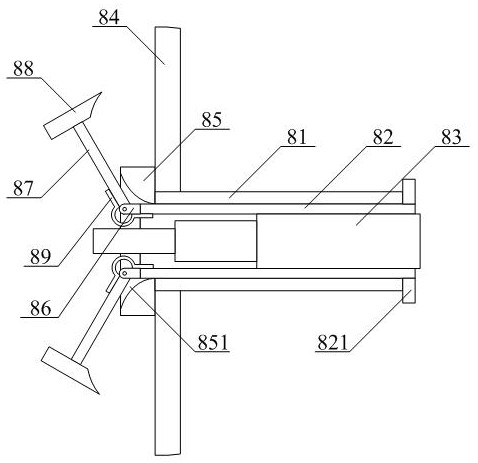

Anti-crystallization freeze-crack urea nozzle

ActiveCN113565605BReduce vibrationExtended service lifeInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

Owner:YANTAI YINGDE PRECISION MASCH CO LTD

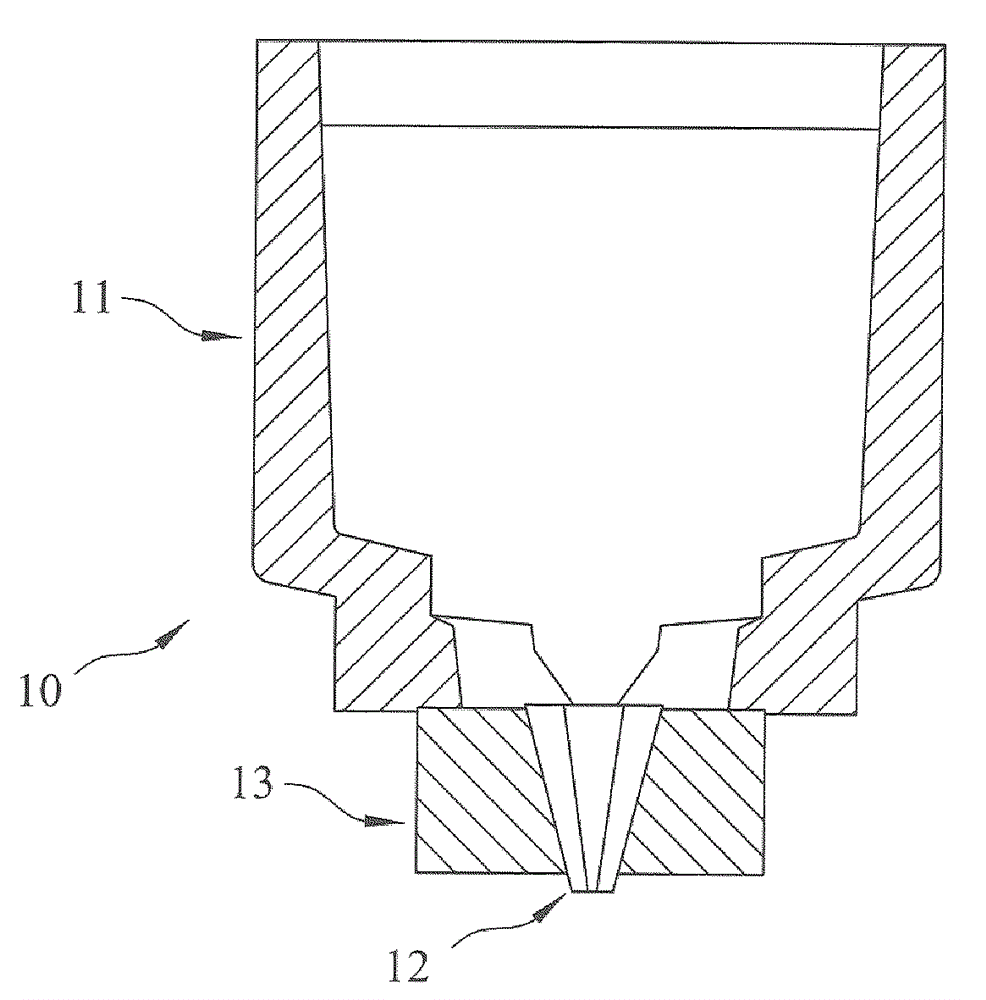

Nozzle device

InactiveCN104907550BPrevent solidificationSmooth casting operationMelt-holding vesselsInsulation layerCrucible

The invention provides a nozzle device mounted on a casting device. The casting device comprises a crucible for accommodating molten steel; and the crucible has a main body and an output port. The nozzle device comprises a support base, a nozzle arranged in the support base, and a first heating unit for heating the nozzle. The support base comprises a base body; and the base body has a stainless steel layer, and a first heat insulation layer positioned at the inner side of the stainless steel layer. The upper end of the nozzle is combined at the bottom of the main body, and is communicated with the output port. The first heating unit comprises two first heating pieces arranged in the base body at an interval and used for heating the nozzle. Therefore, the first heating pieces can heat the nozzle to prevent the molten steel from condensing when flowing through the nozzle; and the first heat insulation layer of the base body can effectively isolate high temperature, and fits the stainless steel layer to improve the whole rigidity, thereby improving cracks caused by high-temperature thermal shock.

Owner:CHINA STEEL

Dual-purpose steam water boiler convenient to feed manually

InactiveCN107388237AQuick addProtection securityBoiler cleaning apparatusSolid fuel combustionFurnace temperatureProcess engineering

The invention relates to a steam-water dual-purpose boiler which is convenient for manual feeding, which comprises a pot body and an inner furnace installed in the pot body. The smoke outlet connected to the inner furnace, the upper furnace door and the lower furnace door distributed up and down, the dust removal port connected to the inner furnace at the bottom of the pot body, and the upper furnace door is connected to the feed material whose bottom surface is arranged obliquely upward from left to right A baffle is hinged at the connection between the feed hopper and the upper furnace door. The invention isolates the furnace door and the feed end through the design of the hopper, so that when adding fuel, it can ensure that the temperature in the furnace will not be lost, and can also isolate the high temperature from the furnace to protect the safety of operators and realize rapid fuel injection. Adding, easy to use, greatly reducing the occurrence of hidden dangers of accidents.

Owner:芜湖市通达锅炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com