Energy-saving and environment-friendly heat accumulating type waste gas incinerator

An energy-saving and environmentally friendly incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of easy generation of smoke and dust in exhaust gas, high replacement cost of insulation materials, and outward heat dissipation, so as to achieve the effect of saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

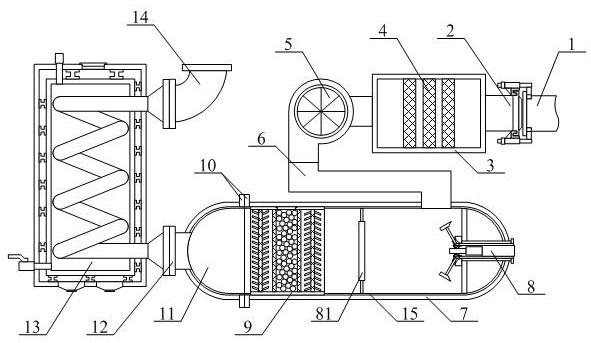

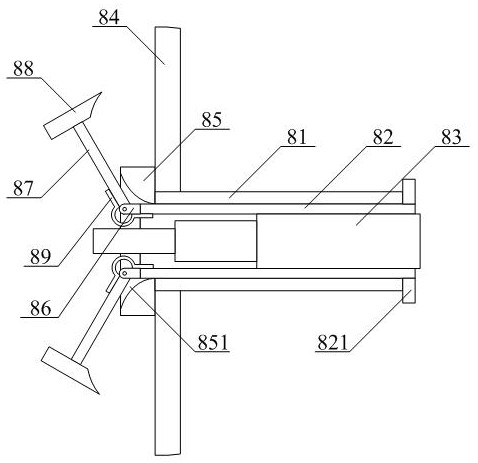

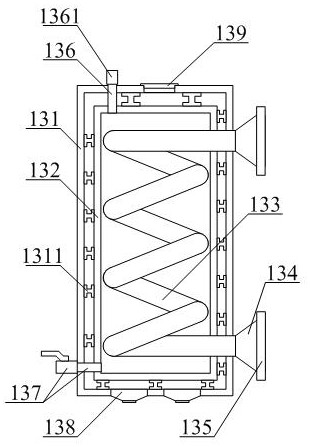

[0036] as attached figure 1 And attached figure 2 As shown, an energy-saving and environment-friendly regenerative waste gas incinerator includes a waste gas generating equipment outlet pipe 1, a pipe clamping frame structure 2, a filter box 3, a main filter screen 4, a fan 5, a waste gas conveying pipe 6, and an incinerator 7 , nozzle removal frame structure 8, flue gas filter frame structure 9, mounting flange 10, furnace cover 11, end connecting flange 12, reinforced heat storage tank structure 13, chimney connecting pipe 14 and heat insulation pad 15, the The pipe clamping frame structure 2 is clamped on the left side of the exhaust pipe 1 of the exhaust gas generating equipment; the filter box 3 is welded on the left side of the pipe clamping frame structure 2; the main filter screen 4 is bolted to the filter box 3; the fan 5 is bolted to the left side of the filter box 3, and the inlet is connected to the inside of the filter box 3; one end of the waste gas delivery pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com