A compound joint structure of counterweight layer for large-diameter submarine pipeline

A submarine pipeline and layer composite technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of premature curing of open-cell polyurethane foam, incomplete mold filling, long time required, etc., to achieve The effect of reducing foam curing time, reducing dosage, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

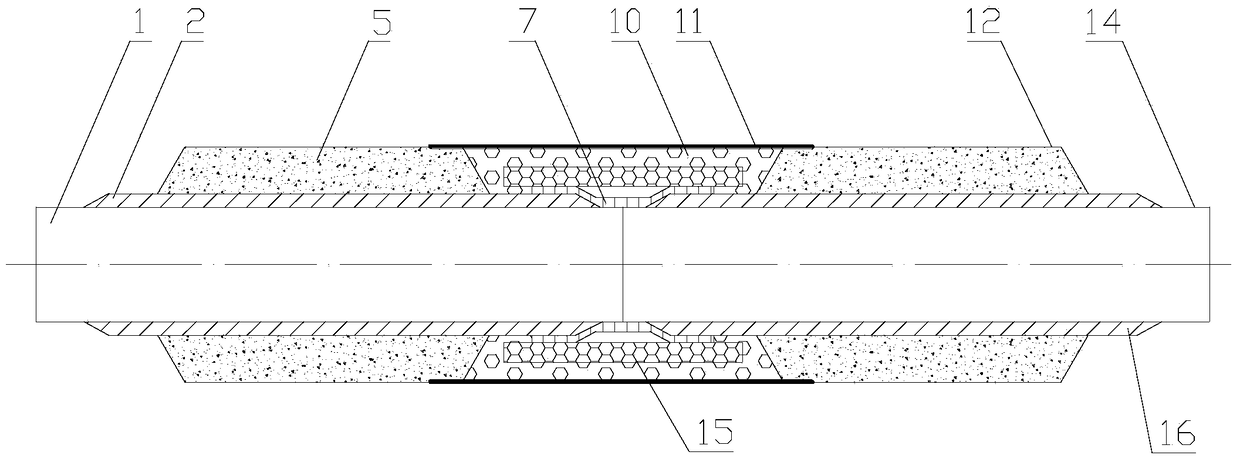

[0024] In the embodiment of the present invention, such as figure 1 As shown, the counterweight pipe connected during the laying of the large-diameter submarine pipeline provided by the present invention is composed of a steel pipe 1 and a pipe body anti-corrosion layer 2 and a concrete weight layer 5 that are sequentially coated on the outside of the steel pipe 1. Submarine single layer weight tube. The pipe body anticorrosion layer 2 of the pipe wall of the steel pipe 1 can be selected from epoxy paint, three-layer polyethylene anticorrosion layer, fusion-bonded epoxy powder anticorrosion layer or double-layer epoxy powder anticorrosion layer. The steel pipe 1 can be a carbon steel pipe or a stainless steel pipe with an outer diameter of 426mm-1420mm and a length of 8-15m. The two ends of the reserved welding section 14 of the steel pipe are respectively 150mm-200mm long. The thickness of the concrete counterweight layer 5 of the large-diameter submarine pipeline is 70-120...

Embodiment 2

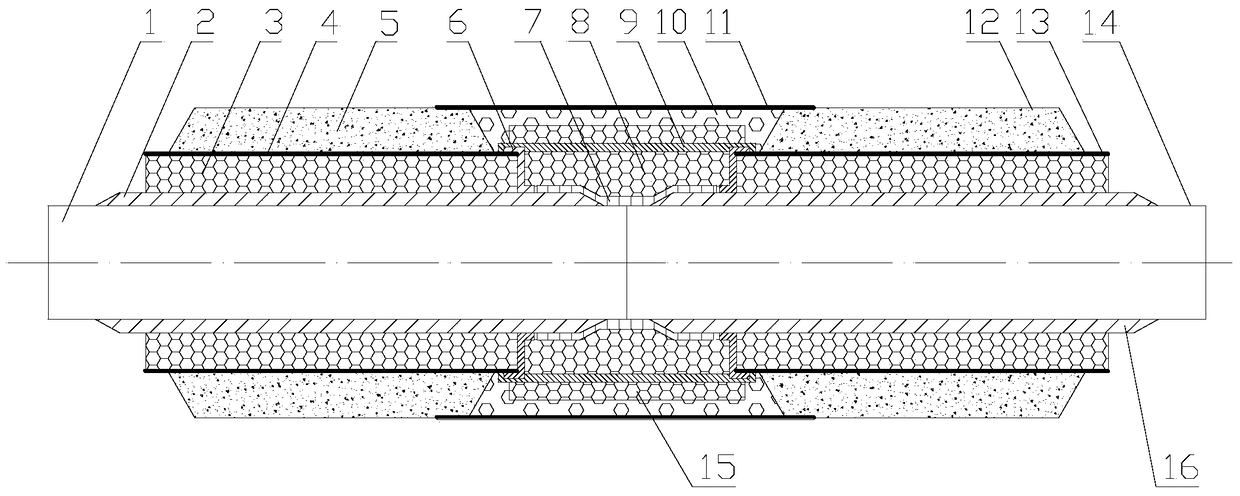

[0029] In the embodiment of the present invention, such as image 3 As shown, the counterweight pipe connected when the large-diameter submarine pipeline provided by the present invention is to adopt the steel pipe 1 and the pipe body anticorrosion layer 2, polyurethane foam insulation layer 3, high A seabed single-layer insulation weight pipe composed of a density polyethylene outer protection pipe 4, a concrete weight layer 5 and a waterproof cap 6 at the end of the pipe body. The pipe body anticorrosion layer 2 of the pipe wall of the steel pipe 1 can be selected from epoxy paint, three-layer polyethylene anticorrosion layer, fusion-bonded epoxy powder anticorrosion layer or double-layer epoxy powder anticorrosion layer. The steel pipe 1 can be a carbon steel pipe or a stainless steel pipe with an outer diameter of 426mm-1420mm and a length of 8-15m. The two ends of the reserved welding section 14 of the steel pipe are respectively 150mm-200mm long. The length of the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com