Piston of alcohol fuel internal combustion engine

An alcohol-based fuel, internal combustion engine technology, applied in pistons, mechanical equipment, engine components, etc., can solve the problems of high compression ratio, high burst pressure, low mechanical strength, etc., to increase wear resistance and self-lubrication, reduce The effect of reciprocating inertial force and preventing oil burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

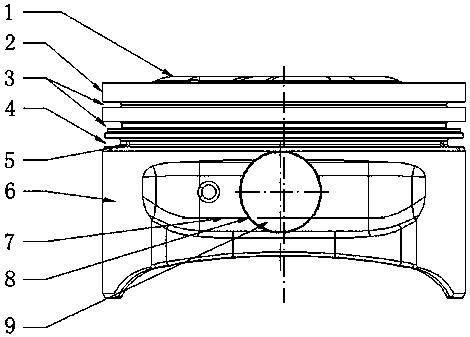

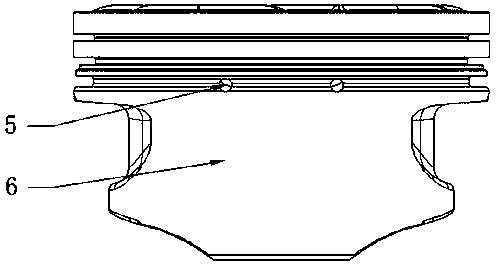

[0027] A kind of piston of alcohol fuel internal combustion engine, its composition comprises: piston top 1, piston head 2, piston skirt 6 and piston pin seat 8, described piston top constitutes a part of combustion chamber of internal combustion engine, described piston top is Formed top, in which the cross-section of the raised part is approximately waist-circular, and the rest is a flat top structure. The top of the piston is provided with a valve avoidance pit, and the head of the piston is mainly composed of a rectangular fire bank and two air ring grooves. 3 and the oil ring groove 4, the two gas ring grooves are installed into the gas ring for heat conduction, the oil ring groove is installed into the combined oil ring scraping cloth oil, auxiliary gas seal, the oil ring There is a circular oil return hole 5 in the ring groove, and its opening passes through the upper part of the oil ring ring groove and the top of the piston skirt and the inner cavity of the piston. El...

Embodiment 2

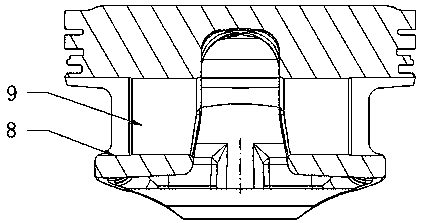

[0029] According to the piston of the alcohol fuel internal combustion engine described in embodiment 1, a piston pin hole 9 is provided on the described piston pin seat, and the described piston pin hole is a special-shaped pin hole, and in the axial direction of the described piston pin hole, The diameter of the piston axis direction from both ends is getting bigger and bigger, and the center line of the piston pin hole is offset to the side under the side pressure in the power stroke, and the piston pin runs at a high speed in the piston pin hole.

Embodiment 3

[0031] The piston of the alcohol fuel internal combustion engine according to the embodiment 1 or 2 is characterized in that: the anodized layer on the inner surface of the piston pin hole enhances its surface wear resistance, the entire surface of the piston is anodized, and the thickness of the oxide layer is 12 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com