Nozzle device

A nozzle device and nozzle technology, which are used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of insufficient rigidity, inconvenience in manufacturing and production, and inability to smoothly cast, so as to improve cracks, improve rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

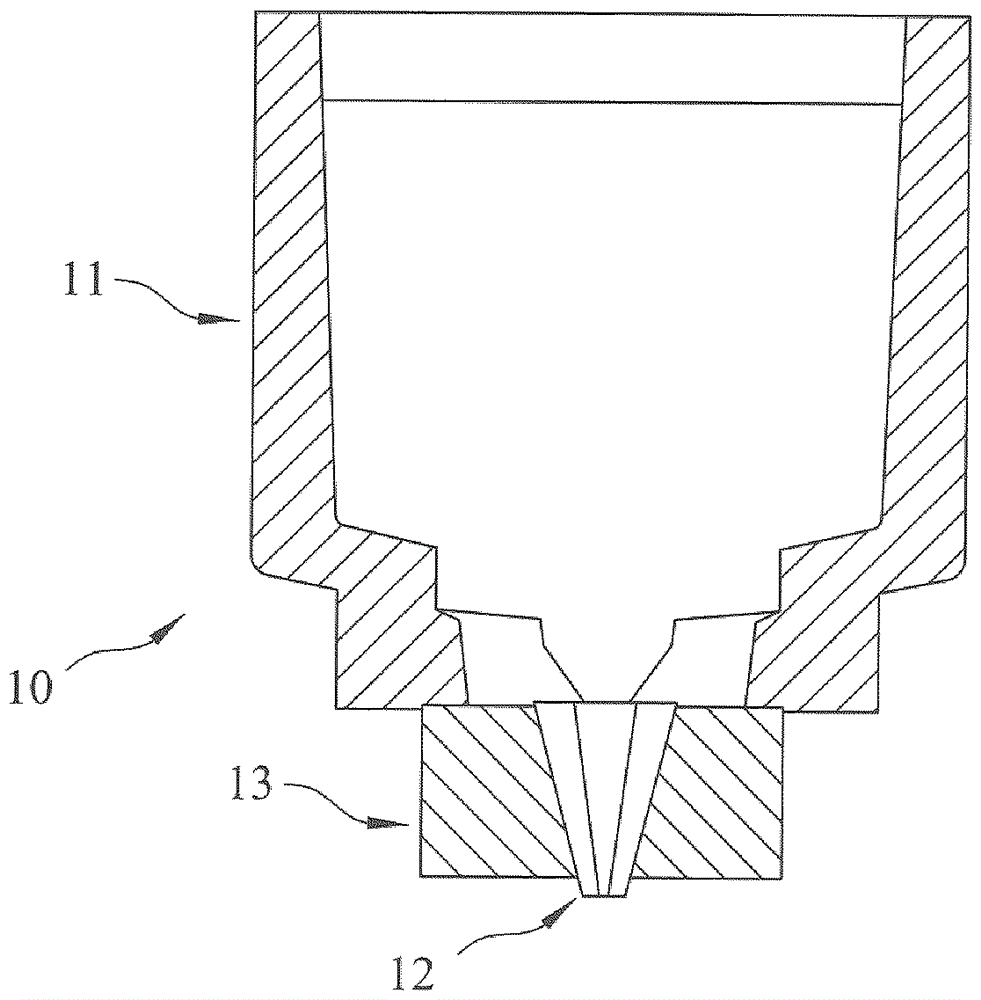

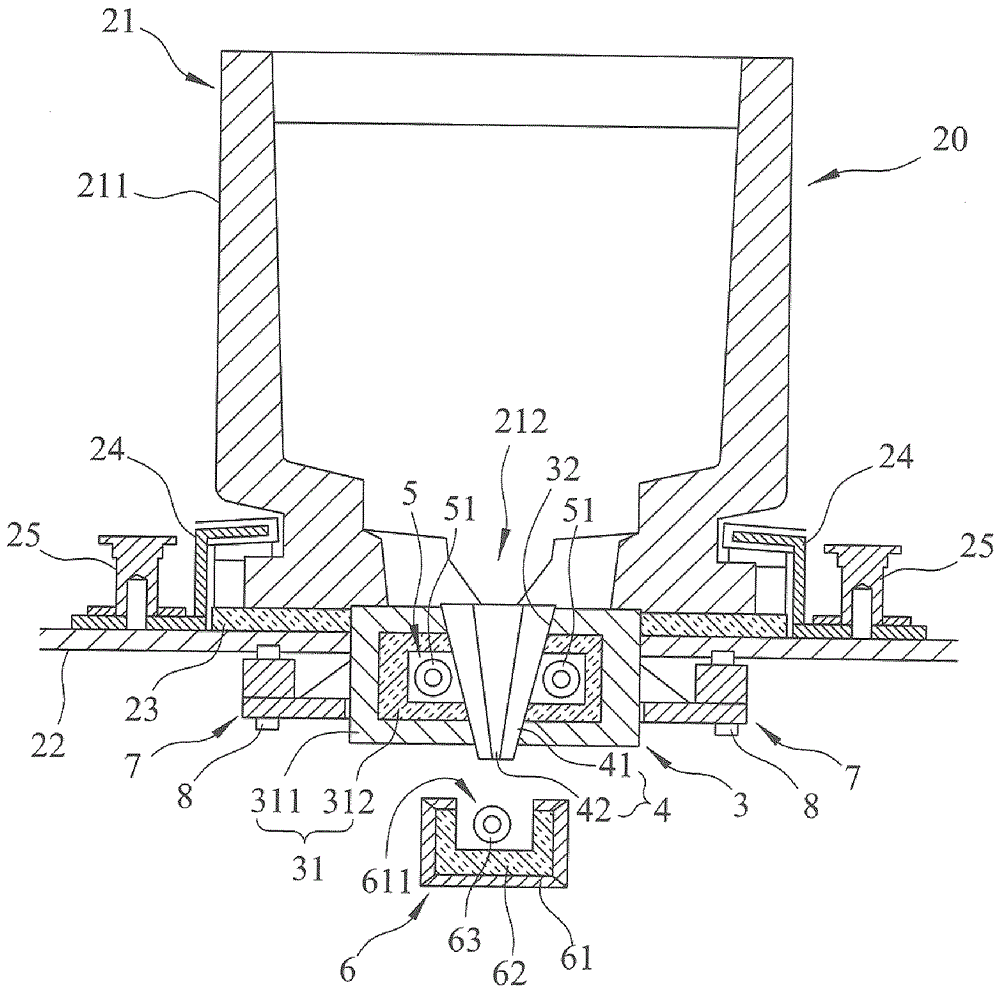

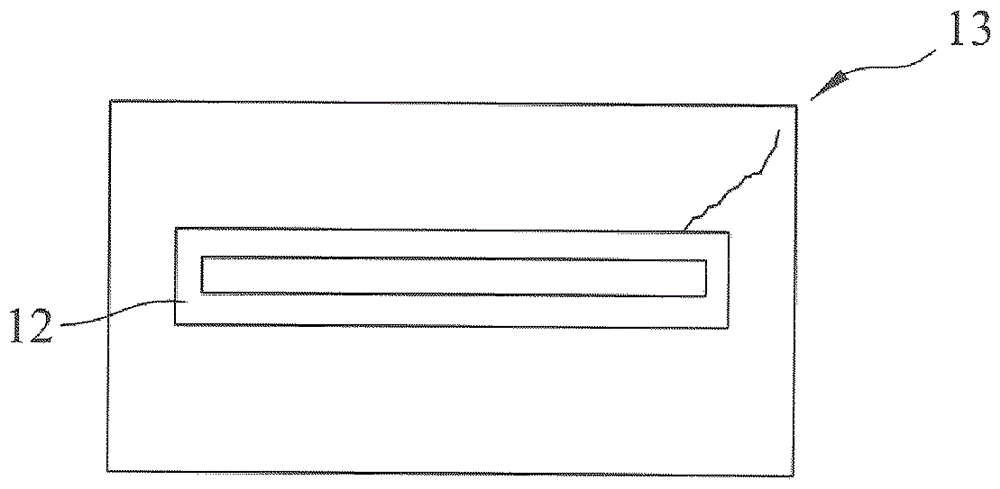

[0012] see image 3 , which shows a preferred embodiment of the nozzle device of the present invention, the nozzle device is installed on the casting device 20, and the casting device 20 includes a crucible 21 for containing molten steel, a crucible 21 positioned below the crucible 21 and used to support the crucible 21 Support steel plate 22, be arranged on this crucible 21 and the insulating heat shield 23 between this support steel plate 22, a plurality of crucible pressure plates 24 for positioning this crucible 21 on this support steel plate 22, and a plurality of for this crucible 21 The crucible pressing plate 24 is locked to the elastic bolt 25 on the supporting steel plate 22 . The crucible 21 has a body 211 for containing molten steel, and an output port 212 disposed at the bottom of the body 211 . Position the crucible 21 on the insulation and heat shield 23 by means of the crucible pressure plate 24 and make it press down and connect or fix it on the support steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com