Automobile electronic exhaust active valve structure

An automotive electronic and active technology, applied in the direction of valve housing structure, lift valve, valve details, etc., can solve problems such as increasing manufacturing difficulty, many gaps between parts and parts, and quality risks of manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

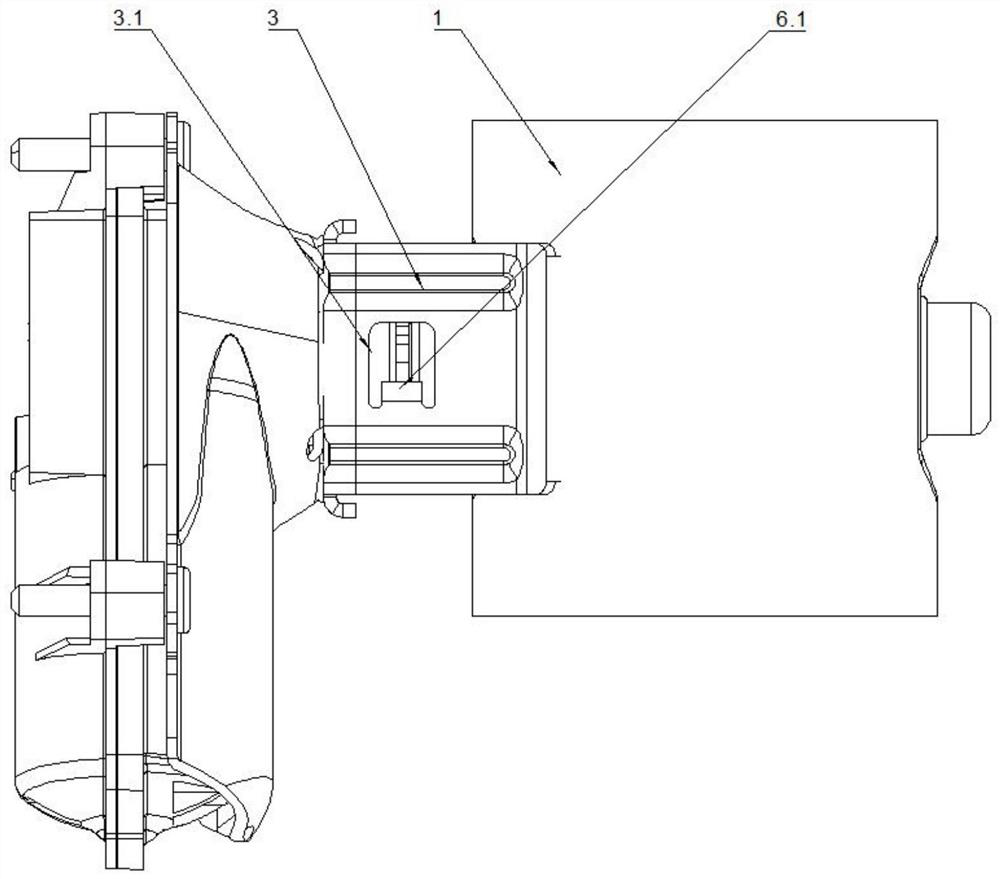

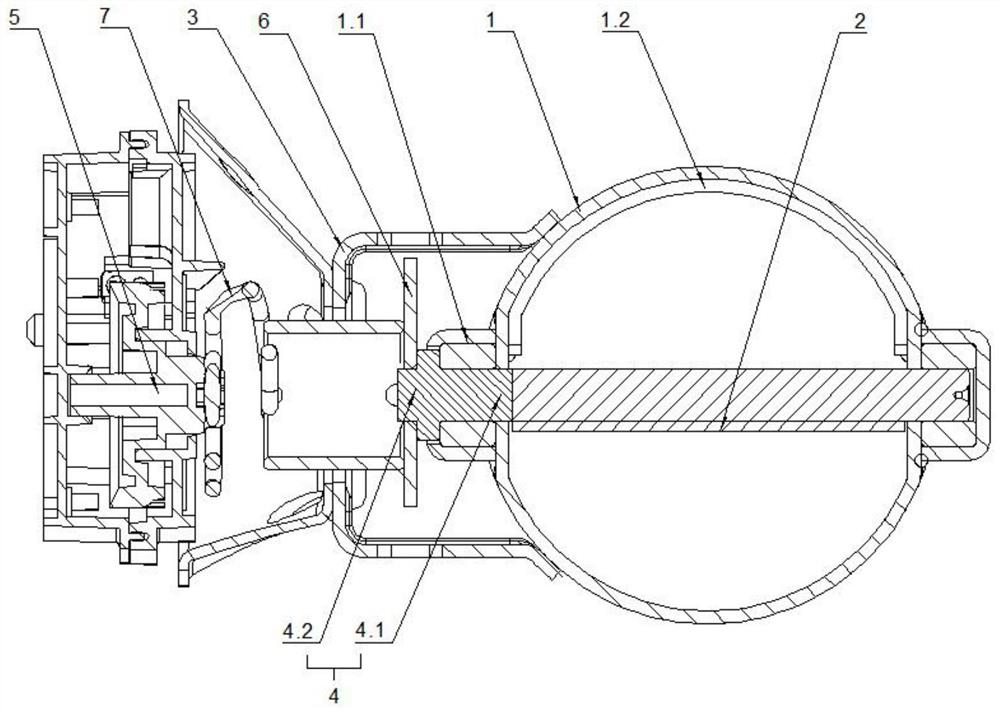

[0025] see figure 1 and figure 2 , the embodiment of the present invention provides an active electronic exhaust valve structure for automobiles, including a valve body 1, a valve plate 2, a limit seat 3, a main shaft 4 and a power source 5, and the side of the valve body 1 is provided with a socket 1.1 , the main shaft 4 is rotatably connected to the socket 1.1, the main shaft 4 includes a first end 4.1 connected with the valve plate 2 and a second end 4.2 provided with an elastic adapter, the power source 5 Used to drive the elastic adapter to rotate, the limiting seat 3 is connected to the valve body 1 , and the limiting seat 3 is provided with a positioning part for conflicting with the elastic adapter.

[0026] Compared with the prior art, the above solution can control the opening angle of the valve plate 2 by controlling the relative position of the elastic adapter and the limit seat 3, and the structure is stable and easy to adjust.

[0027] In this embodiment, the ...

Embodiment 2

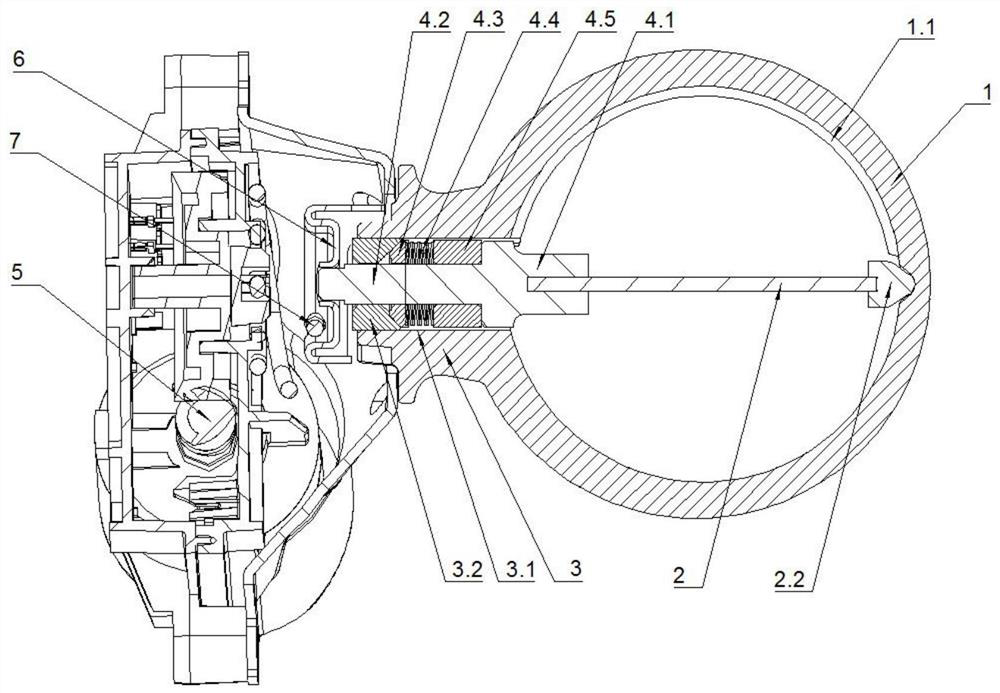

[0031] see Figure 3-Figure 5 , this embodiment 2 is basically the same as embodiment 1, the difference is that a limit ring 1.3 is provided in the jack 1.1, the main shaft 4 is inserted into the limit ring 1.3, and the middle part of the main shaft 4 is sleeved There is an aligning piece 4.3 and a spring 4.4, the aligning piece 4.3 is located between the limiting ring 1.3 and the spring 4.4, the side of the limiting ring 1.3 close to the aligning piece 4.3 is funnel-shaped, the The side of the self-aligning piece 4.3 close to the limit ring 1.3 is tapered, and the approach of the spring 4.4 is used to push the self-aligning piece 4.3 to interfere with the limit ring 1.3.

[0032] Embodiment 2 mainly achieves the effect of quickly assembling the main shaft 4 and the valve plate 2 on the valve body 1 through the setting of the limiting ring 1.3, the aligning piece 4.3 and the spring 4.4. Specifically, when assembling, the aligning piece 4.3 and the spring 4.4 are first sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com