Built-in compartment type particle inertial-capacitance damper

A damper and particle technology, used in protective buildings/shelters, bridge parts, bridge construction, etc., can solve problems such as multiple tuning capabilities without its own energy consumption capacity, achieve affordable and easy-to-obtain raw materials, reduce wind The effect of load, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

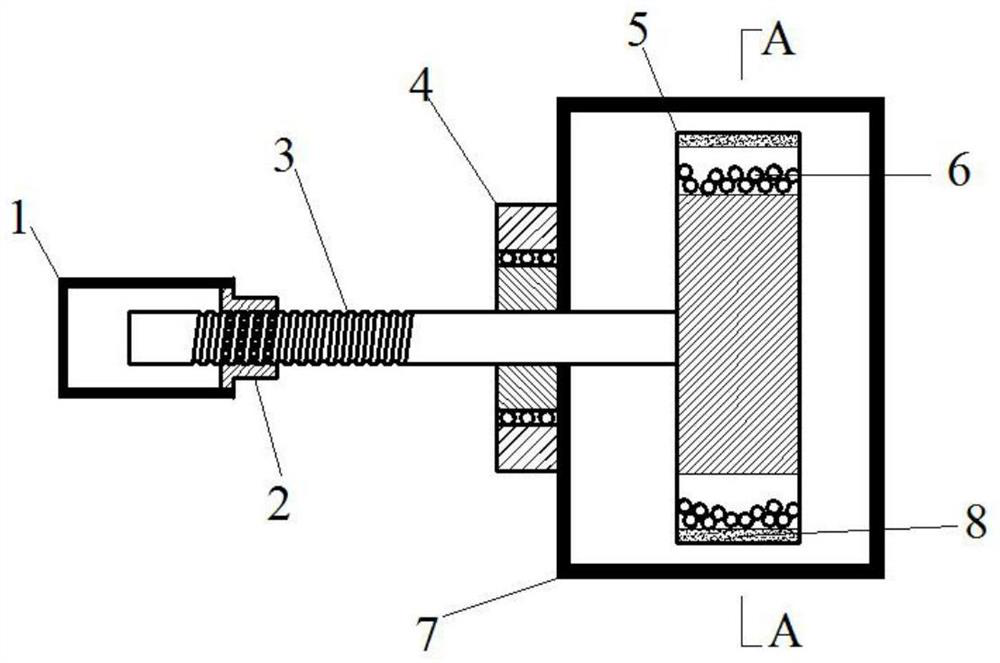

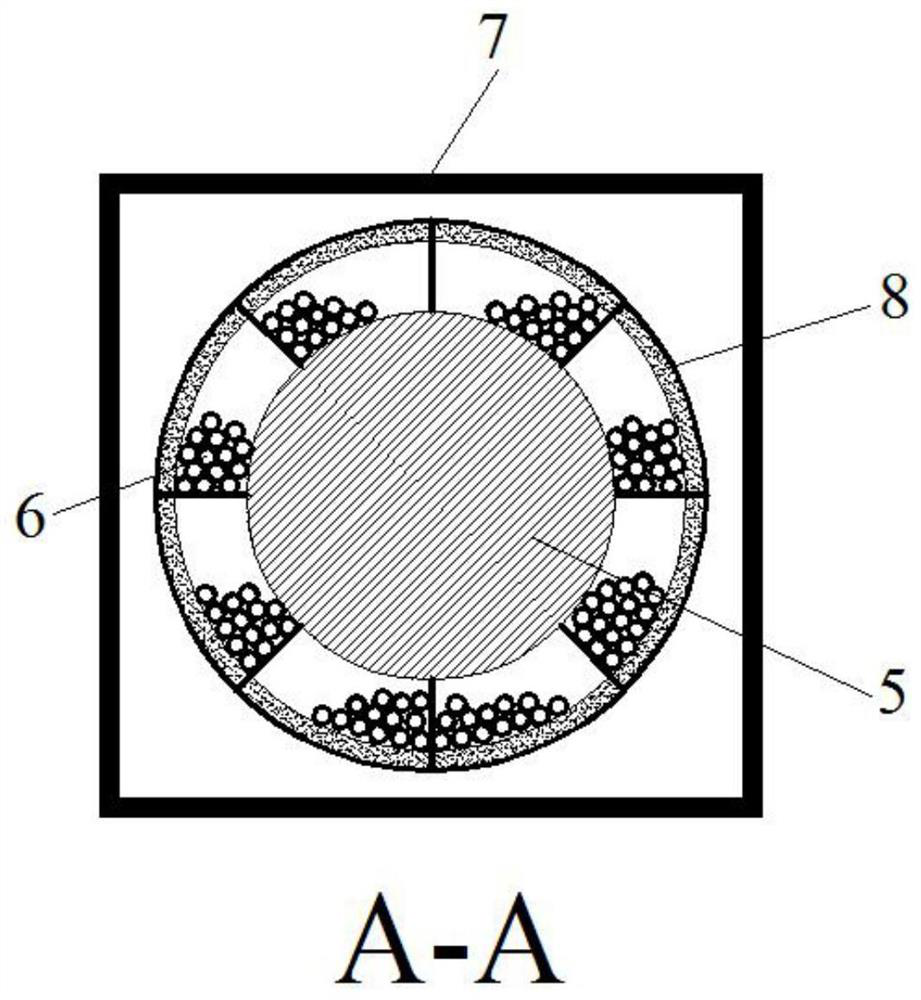

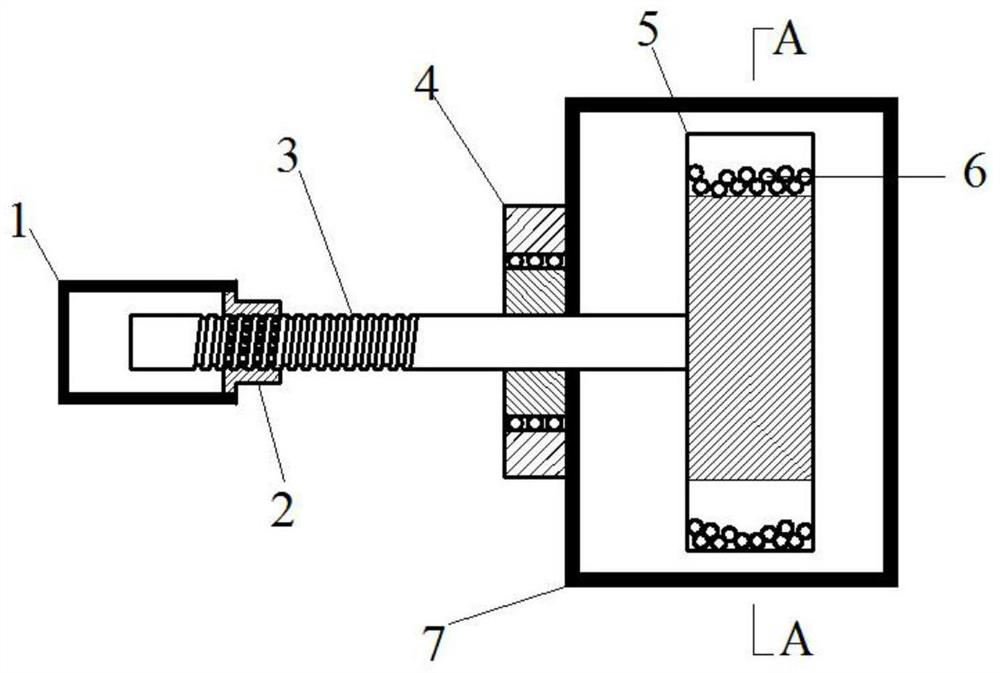

[0022] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Shown is a built-in compartment particle inertial capacity damper, which is mainly used between bridge piers and beams to play a role in shock absorption (vibration). It includes a metal casing one (1), a nut (2), a ball screw (3), a bearing (4), a flywheel (5), particles (6), a metal casing two (7) and an energy dissipation layer (8). Metal case one (1) has a size of 300mm×130mm×100mm and a thickness of 10mm; metal case two (7) has a size of 300mm×300mm×300mm and a thickness of 10mm; the ball screw (3) has a diameter of 50mm and a length according to The maximum displacement of the controlled structure is determined. The flywheel (5) has a diameter of 250 mm and a thickness of 150 mm. The size of the internal compartments is the same. The diameter of the particles (6) is 9 mm. 45%, the thickness of the built-in energy-dissipating layer (8) is between 10mm and 30mm, the mass ratio of the ent...

Embodiment 2

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Shown is a built-in compartment type particle inertial capacity damper, which is mainly used in the interlayer of high-rise buildings or in the buffer layer of blasting structures to play the role of shock absorption (vibration). It includes a metal casing one (1), a nut (2), a ball screw (3), a bearing (4), a flywheel (5), particles (6), a metal casing two (7) and an energy dissipation layer (8). Metal case one (1) has a size of 500mm×170mm×130mm and a thickness of 15mm. Metal case two (7) has a size of 500mm×500mm×500mm and a thickness of 15mm. The ball screw (3) has a diameter of 100mm and a length according to The maximum displacement of the controlled structure is determined. The flywheel (5) has a diameter of 400mm and a thickness of 250mm. The internal compartments of the flywheel (5) have different sizes according to the shock absorption requirements. The diameter of the particles (6)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com