Vibration-free anti-slip lane and construction method thereof

A construction method and slideway technology, applied to roads, roads, pavement details, etc., can solve problems such as difficult maintenance and maintenance, insufficient roughness of the surface, small friction coefficient, etc., to eliminate splashing water and water mist, rough surface, and friction The effect of large coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

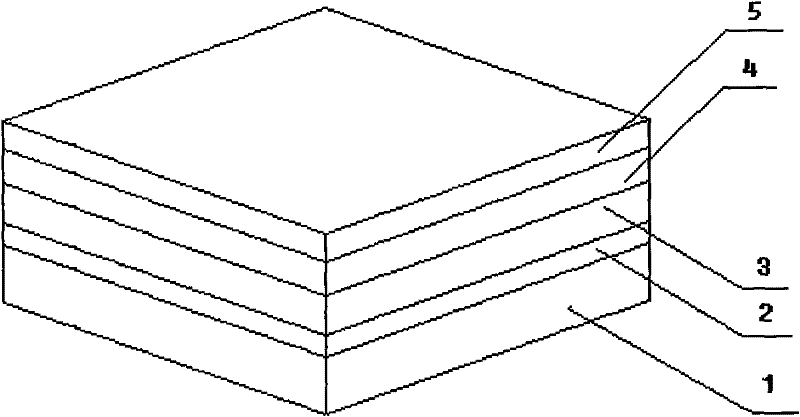

[0059] Such as figure 1 The non-vibration anti-skid lane shown is composed of concrete floor 1, sealing layer 2, pressure-resistant layer 3, anti-skid layer 4 and surface maintenance layer 5 from bottom to top, wherein the sealing layer is sprayed on the concrete floor by a sprayer. Carbonized interface sealant (water-based epoxy modified resin) is formed, and the thickness of the sealing layer is 1mm; the anti-pressure layer is to use a flat spatula to brush high molecular polymer aggregate (Poland cement and corundum, quartz sand) on the sealing layer mixture) and modified resin, and the coating thickness is 3.0mm; the anti-skid layer is sprayed with high molecular polymer aggregate (the mixture of Portland cement, corundum and quartz sand) and modified resin on the anti-skid layer. It is formed on the laminated layer, and the spray thickness is 3.0mm; the surface maintenance layer is formed by spraying about 0.1mm thick acrylic acid polymer curing agent on the anti-skid lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com