Concentrated composition of waste rubber composite modified pitch and preparation and use method

A technology for compounding modified asphalt and waste rubber, which is used in building structures, building components, building insulation materials, etc., can solve the problem that mixing equipment and shearing equipment cannot meet product production, and are not suitable for long-term storage and long-distance transportation and storage. problems such as poor stability and transportation stability, to achieve the effect of increasing high temperature rutting resistance, improving driving comfort and safety, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to parts by weight, get 40 parts of 80 mesh waste tire rubber powder, 40 parts of Korean SK petroleum asphalt with the label of 90, 5 parts of rock asphalt, 5 parts of SBR, and the density is 0.92g / cm 3 5 parts of PE, 5 parts of aromatic oil, 4 parts of sulfur powder.

[0043] After heating the above-mentioned petroleum asphalt to 150°C, add it into the mixing kettle, add waste tire rubber powder and aromatic oil into the mixing kettle, mix it into a uniform mixture, and then pass the mixture into the shearing machine, and after shearing , into the swelling tank, swelling and development for 40 minutes; the swollen mixture, rock asphalt, SBR, density of 0.92g / cm 3 The low-density PE and sulfur are added into the stirring equipment, and the concentrated composition of waste rubber composite modified asphalt is prepared.

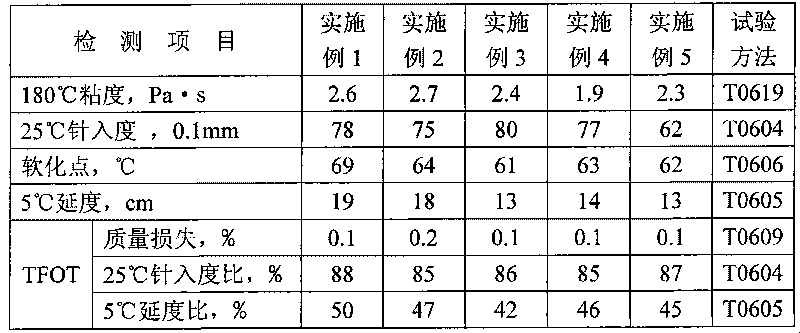

[0044] The base asphalt is heated to 145°C, and the prepared waste rubber composite modified asphalt concentrated composition and base aspha...

Embodiment 2

[0046] According to parts by weight, get 50 parts of 20 mesh waste tire rubber powder, 50 parts of blue refining petroleum asphalt whose label is 110, 10 parts of lake asphalt, 10 parts of CR, 10 parts of waste polyethylene, 10 parts of aromatic oil, 8 parts of carbon black .

[0047] After heating the above-mentioned road petroleum asphalt to 160°C, add it into the mixing kettle, add waste tire rubber powder and aromatic hydrocarbon oil into the mixing kettle, mix it into a uniform mixture, then pass the mixture into the shearing machine, and pass through the shearing machine. Cut, enter the swelling tank, and swell and develop for 60 minutes; add the swollen mixture, lake asphalt, CR, waste polyethylene, and carbon black powder into the mixer to prepare a concentrated composition of waste rubber composite modified asphalt.

[0048] Heat the base asphalt to 160°C, add the prepared concentrated composition of waste rubber composite modified asphalt to the base asphalt in a wei...

Embodiment 3

[0050] According to parts by weight, get 30 parts of 100 mesh waste tire rubber powder, 30 parts of Karamay petroleum asphalt with the label of 50, 1 part of rock asphalt, 1 part of SBR, 1 part of polyolefin wax, 1 part of furfural extraction oil, and 1 part of sulfur powder .

[0051] After heating the above-mentioned road petroleum asphalt to 120°C, add it into the mixing kettle, add the waste tire rubber powder and furfural oil into the mixing kettle, mix it into a uniform mixture, then pass the mixture into the shearing machine, and Cut, enter the swelling tank, and swell and develop for 20 minutes; add the swollen mixture, rock asphalt, SBR, polyolefin wax, and sulfur powder into the mixer to prepare a concentrated composition of waste rubber composite modified asphalt.

[0052] Heat the base asphalt to 130°C, add the prepared waste rubber composite modified asphalt concentrated composition and base asphalt in a weight ratio of 1:1, add them to the modified asphalt produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com