Composition of cationic asphalt emulsifier, preparation method and application thereof

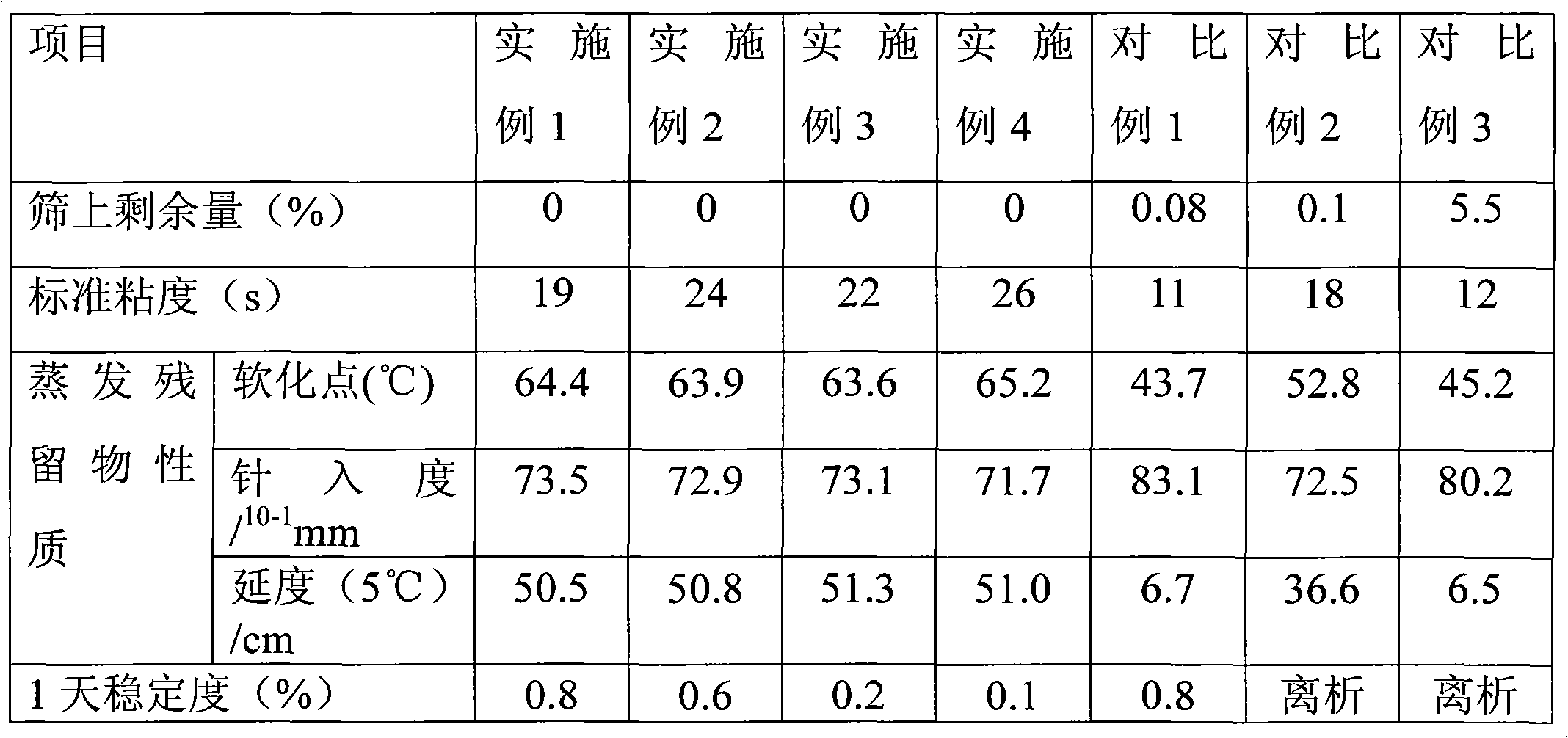

An asphalt emulsifier, cationic technology, applied in chemical instruments and methods, chemical/physical processes, building components, etc., can solve the problems of coarse emulsion particles, insignificant improvement of asphalt high temperature performance, poor storage stability, etc., and achieve good temperature resistance. The effect of improving the strength of the seal layer and its anti-deformation ability, and excellent low-temperature cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of cationic emulsifier: put 35g of octadecylamine, 10g of stearyl-1,3-propylenediamine and 10g of C 17 h 35 -CO-NH-C 2 h 4 -NH 2 , and 10 g of octadecylamine polyoxyethylene ether (AC1802) were sequentially put into 35 g of isopropanol, stirred at 80° C. for 1 h, and mixed uniformly to obtain a cationic emulsifier.

[0016] Preparation of modified asphalt: heat Liaohe 90# base asphalt to 160°C, add 3.5% SBS, keep stirring for 60 minutes, and then use colloid mill to grind for 30-90 minutes to make SBS modified asphalt. Keep the SBS modified asphalt at 165-170°C for later use.

[0017] Preparation of soap solution: Weigh 5 g of the cationic emulsifier, add it to 492 g of hot water, and add 3 g of 36% hydrochloric acid. At this time, the pH value of the solution is 2.0, which is the soap solution. Keep the temperature of the soap solution at 55-60°C.

[0018] Turn on the colloid mill, add 500g of SBS modified asphalt with a temperature of 165°C and the a...

Embodiment 2

[0020] Preparation of cationic emulsifier: put 15g octadecylamine, 25g tallow-1,3-propylenediamine and 20gC 17 h 35 -CO-NH-(C 2 h 4 NH) 4 H, and 15 g of octadecylamine polyoxyethylene ether (AC1810) were put into 25 g of isopropanol in sequence, and stirred at 90° C. for 1 h to obtain a cationic emulsifier.

[0021] Preparation of soap solution: Weigh 6 g of the cationic emulsifier, add it to 341 g of hot water, and add 3 g of hydrochloric acid with a concentration of 36%. At this time, the pH value of the solution is 2.0, which is soap solution. Keep the temperature of the soap solution at 55-60°C.

[0022] Turn on the colloid mill, add 650 g of the SBS modified asphalt prepared in Example 1 at a temperature of 165° C. and the above soap solution into the colloid mill at the same time for shearing to obtain emulsified SBS modified asphalt. This emulsified asphalt is high-viscosity and high-concentration emulsified modified asphalt, which is suitable for ultra-thin wear l...

Embodiment 3

[0024] Preparation of cationic emulsifier: 15g of hydrogenated tallow primary amine, 10g of oleyl-1,3-propylenediamine and 30g of C 17 h 33 -CO-NH-(C 2 h 4 -NH) 4 H, and 10 g of octadecylamine polyoxyethylene ether (AC1820) were put into 35 g of isopropanol in sequence, and stirred at 80° C. for 1 h to obtain a cationic emulsifier.

[0025] Preparation of soap liquid: Weigh 8 g of the cationic emulsifier, add it to 358 g of hot water, and add 4 g of 36% hydrochloric acid. At this time, the pH value of the solution is 2.0, which is soap liquid. Keep the temperature of the soap solution at 55-60°C.

[0026] Turn on the colloid mill, and add 630 g of the SBS modified asphalt prepared in Example 1 at a temperature of 165°C and the above soap solution into the colloid mill for shearing to obtain emulsified SBS modified asphalt. This emulsified asphalt is a high-viscosity emulsified modified asphalt, which is suitable as a modified viscous layer oil for expressways, and can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com