Scanning device for rail seam inspection

A scanning device and track technology, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as inaccurate positioning, poor coupling, and missed detection, and achieve the effects of simple structure, improved accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

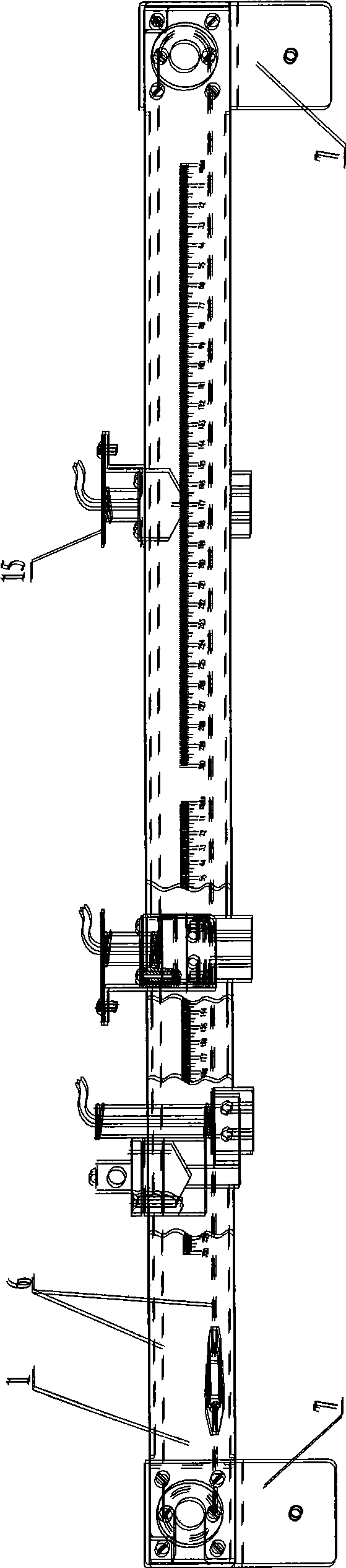

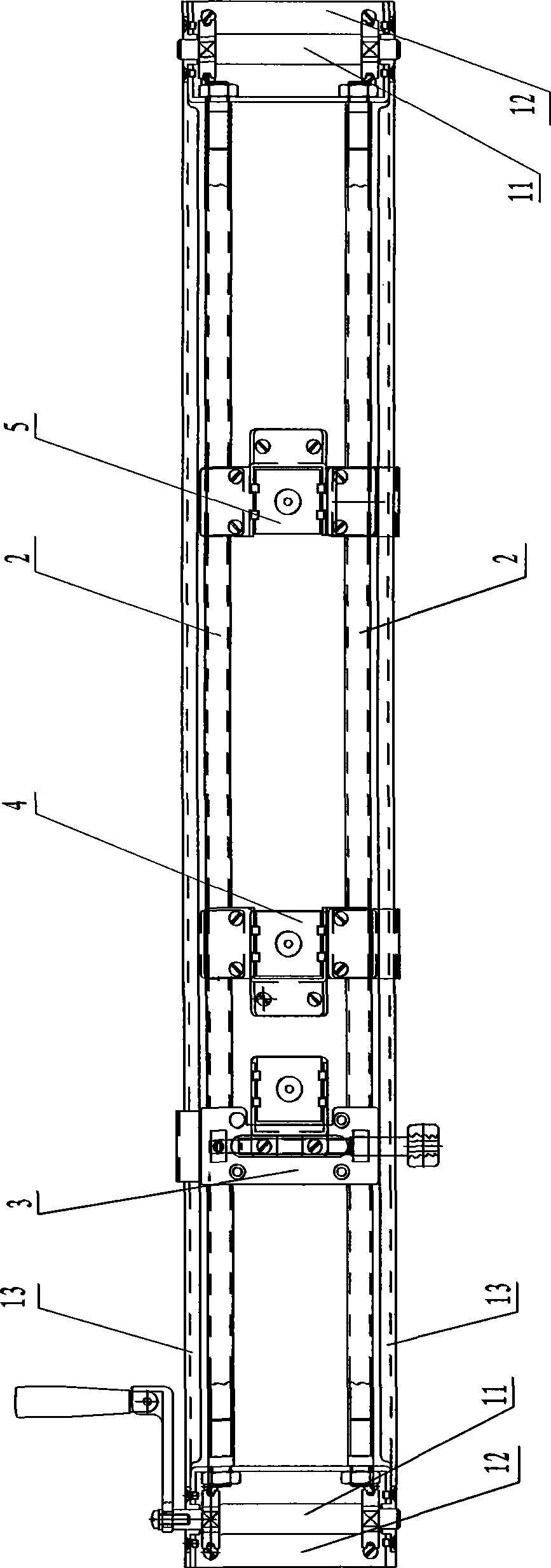

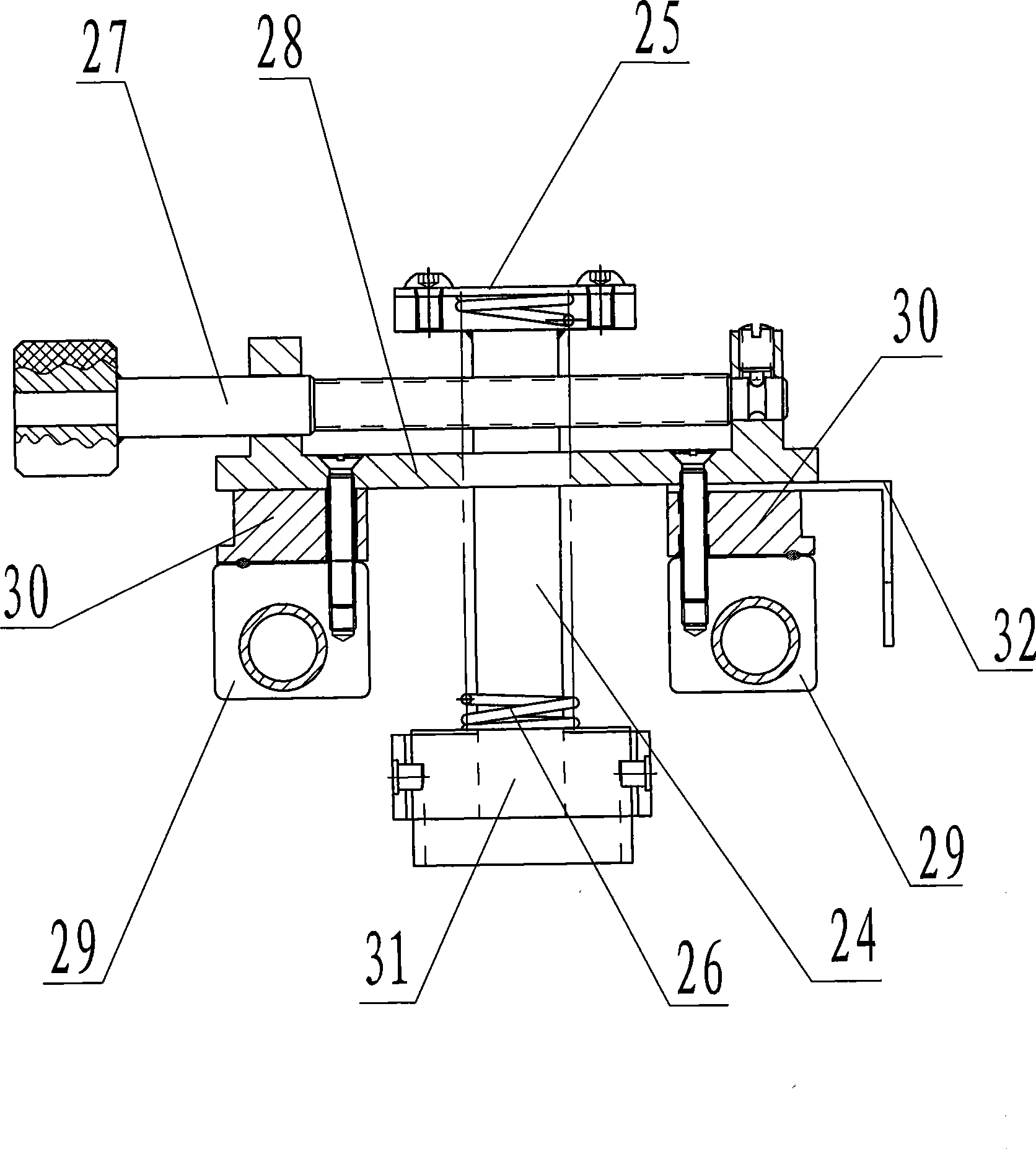

[0019] Such as figure 1 , 2 , 3, 4, and 5 show: a scanning device for rail weld flaw detection, the scanning device includes a rectangular frame-shaped support frame 1, slide rail 2, the first probe box fixing frame 3, the second probe box The fixing frame 4, the third probe box fixing frame 5 and the cable 6, the two ends of the rectangular frame-shaped support frame 1 have "ㄇ"-shaped fixed feet 7; the two ends of the slide rail 2 are fixed on the rectangular frame-shaped support The two ends of the frame 1, the first probe box fixed frame 3, the second probe box fixed frame 4 and the third probe box fixed frame 5 are installed on the slide rail 2 and can slide freely along the slide rail 2, in the Both ends of the rectangular frame-shaped support frame 1 are equipped with drag cable rotating shafts 11, and the drag cables 6 are wound on the two drag cable rotating shafts 11 along the direction of the slide rail 2.

[0020] The rectangular frame support frame 1 is made up o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com