Turnout steel rail damage monitoring method and device

A monitoring device and rail technology, applied in transportation and packaging, railway vehicle shape measuring instrument, railway signal and safety, etc., can solve the problem that small cracks cannot be effectively identified and detect blind spots, so as to avoid unsafe accidents and ensure safety. , The effect of overcoming the detection blind spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention provides a method and device for monitoring rail damage of a turnout, which solves the problem that the rapid development of tiny cracks cannot be effectively identified when the track circuit and large-scale rail inspection vehicles are used to detect the damage of the rail in the prior art. The technical problem of detecting the blind area can effectively identify the tiny cracks on the rail of the turnout and overcome the detection blind area.

[0031] In order to solve the above-mentioned technical problems of detection blind spots, the general idea is as follows:

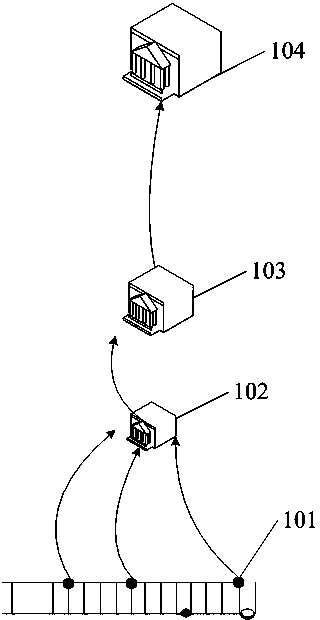

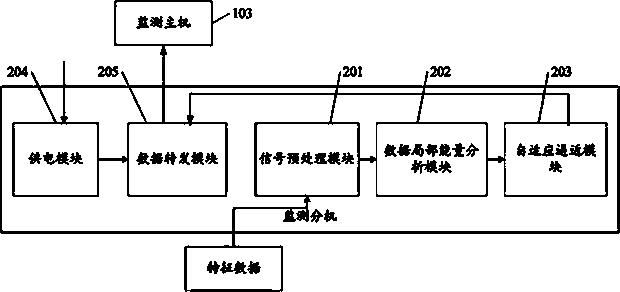

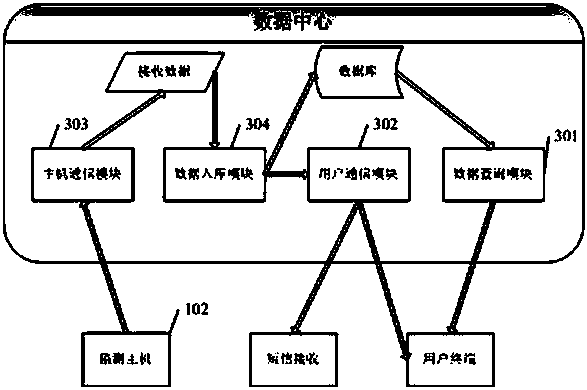

[0032] This scheme adopts a turnout rail damage monitoring device, including sequentially connected sensors, monitoring extension, monitoring host and data center, wherein the sensor is installed on the turnout rail, and the sensor sends the collected characteristic data to the monitoring extension. The feature data is processed, and the processing results are sent to the monitoring host. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com