Intelligent rail inspection machine and method thereof

A machine and track technology, applied in the field of intelligent track inspection machines, can solve problems such as limiting the scope of inspection, inability to realize comprehensive inspection, and limiting the walking path of inspection robots, so as to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

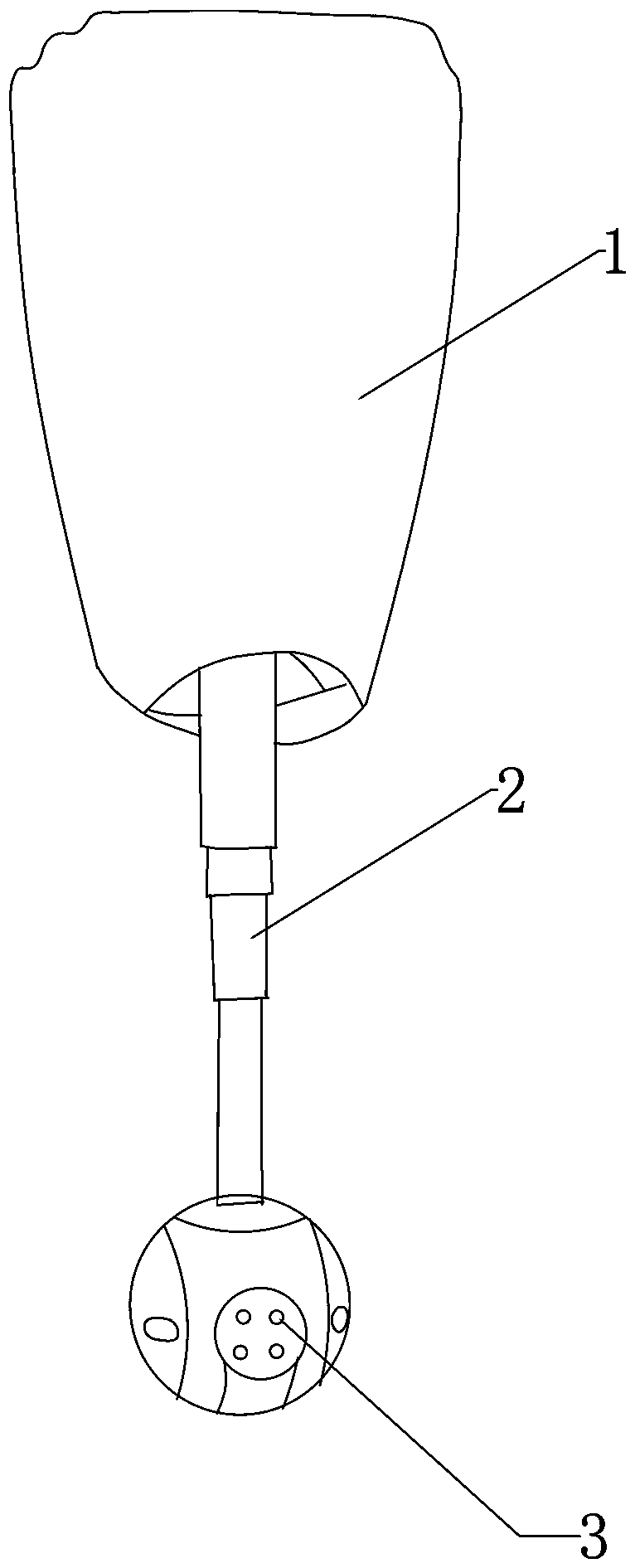

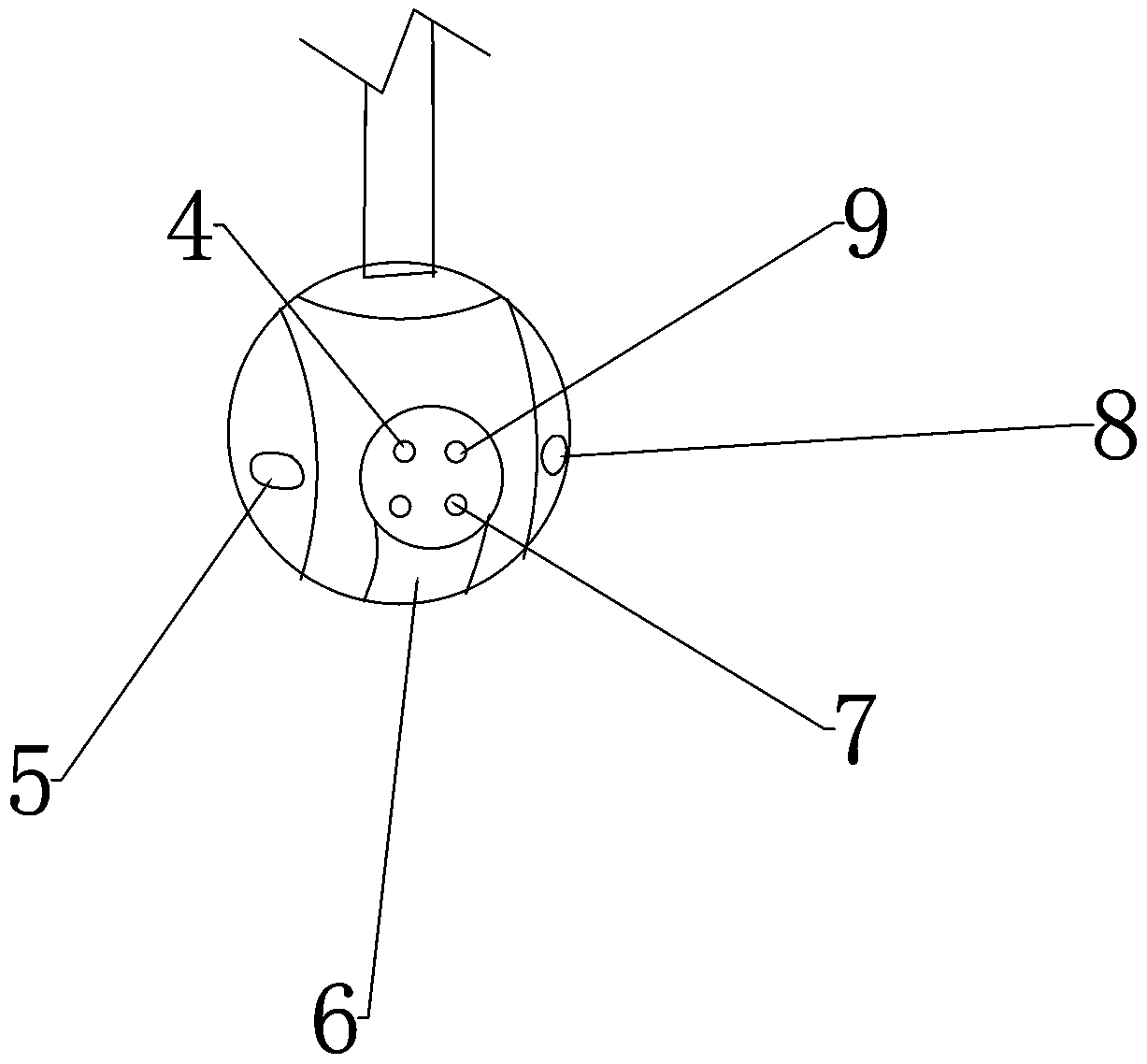

[0022] Such as Figure 1-Figure 5 As shown, an intelligent track inspection machine includes an in-station terminal 11, an inspection machine, and a trolley wire guide rail 12. The inspection machine includes an inspection machine body 1, an inspection machine telescopic rod 2 and an inspection machine camera 3. The inspection machine camera 3 is provided with visible light video surveillance 4, infrared camera 9, high-definition camera 7 and intercom system 6, and the inspection machine camera 3 is equipped with ultrasonic sensors 5 and transient ground waves 8 respectively. .

[0023] The inspection machine camera 3 is a 360° panoramic camera.

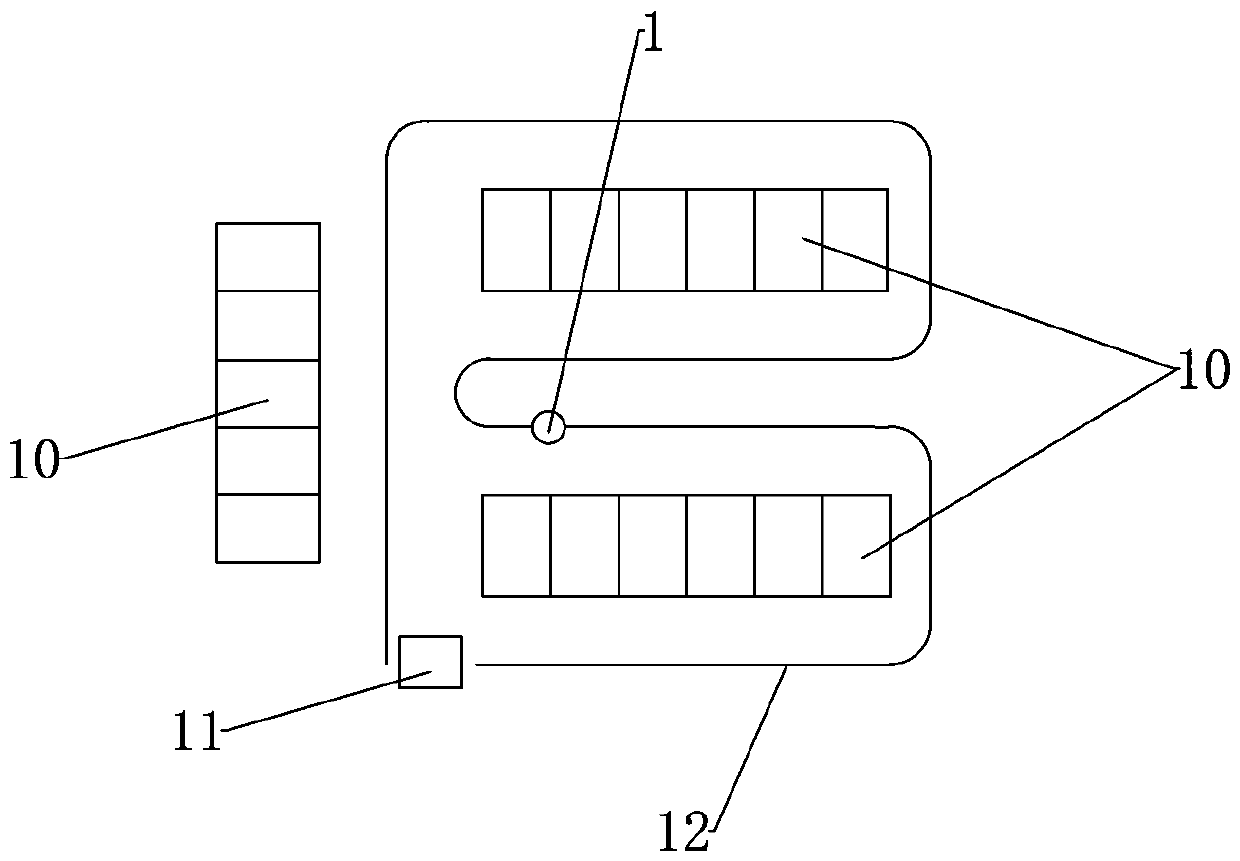

[0024] The station terminal 11 is located in a corner of the room. Three switch cabinets 10 are placed in the room. The sliding contact line guide rails 12 are arranged in a line around the three switch cabinets 10 in the room, and are connected at the two ends of the sliding contact line guide rails 10 An in-station terminal 11 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com