Multifunctional inspection detecting vehicle used for railway steel rail

A multi-functional, flaw detection vehicle technology, applied in the field of high-speed rail flaw detection and multi-functional detection flaw detection vehicles, can solve the problems that the detection vehicle cannot meet the requirements, the detection equipment has a great influence, and the living facilities are not perfected, so as to achieve good work and Living environment, improved accuracy, simple, reasonable and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

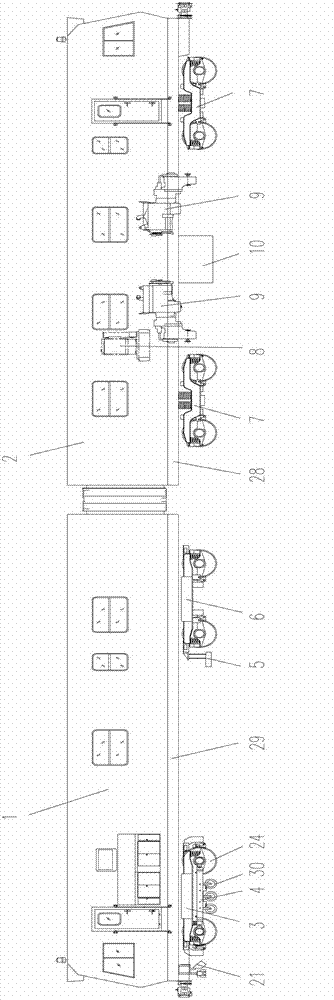

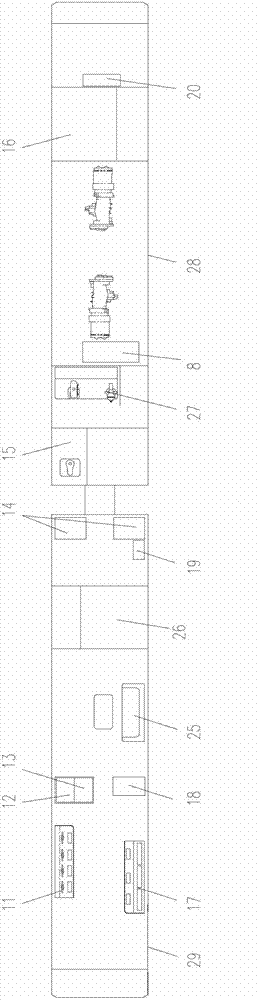

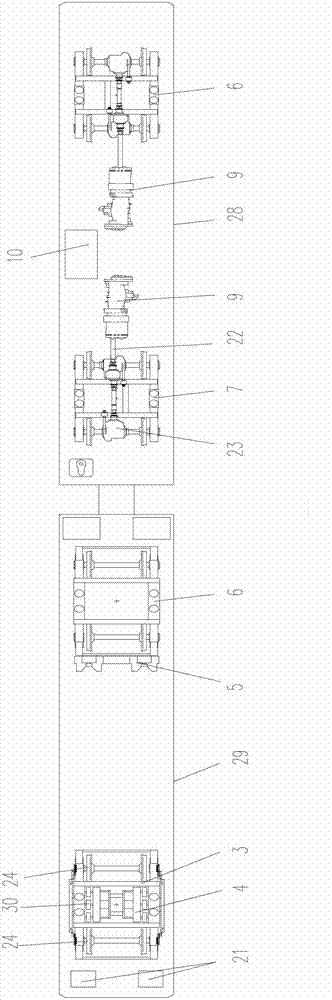

[0022] Attached below Figure 1-5 An embodiment of the present invention is described.

[0023] A multi-functional detection and flaw detection vehicle for railway rails, including a detection vehicle 1 and a tractor 2, the rear end of the tractor 2 is connected to one end of the detection vehicle 1 to drive the detection vehicle 2 to travel, wherein the front bogie 3 of the detection vehicle 1 is mounted on There is a rail flaw detection device 4. Specifically, the rail flaw detection device 4 is arranged under the frame of the front bogie 3, and the detection wheels 30 are arranged between the wheel pairs 24 of the bogie along the direction of the rails, and the detection wheels 30 are in contact with the rails to ensure that the detection wheels 30 It can be centered on the straight line or curve of the rail, and the coupling water tank 14 arranged at the upper end of the car body I 29 of the inspection car 1 provides the flaw detection medium for the rail flaw detection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com