High-speed rail smoothness detection system and method based on satellite positioning and inertial navigation.

A technology of satellite positioning and detection system, applied in railway inspection cars, railway vehicle shape measuring instruments, railway car body parts, etc., can solve the problems of low measurement efficiency, inability to use track adjustment, and low measurement accuracy, and improve work efficiency. , The effect of reducing economic costs and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

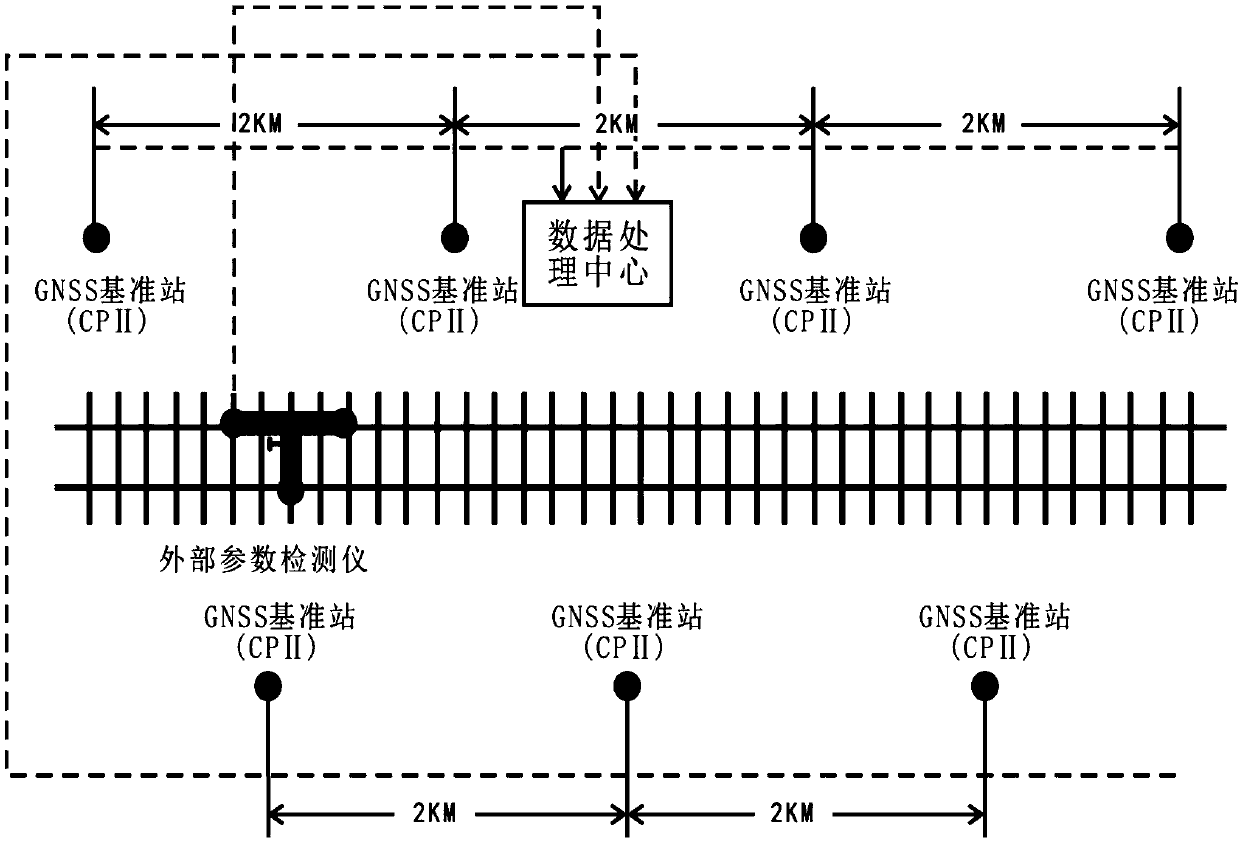

[0030] The invention provides a high-speed rail track smoothness detection system and method based on satellite positioning and inertial navigation, comprising the following steps:

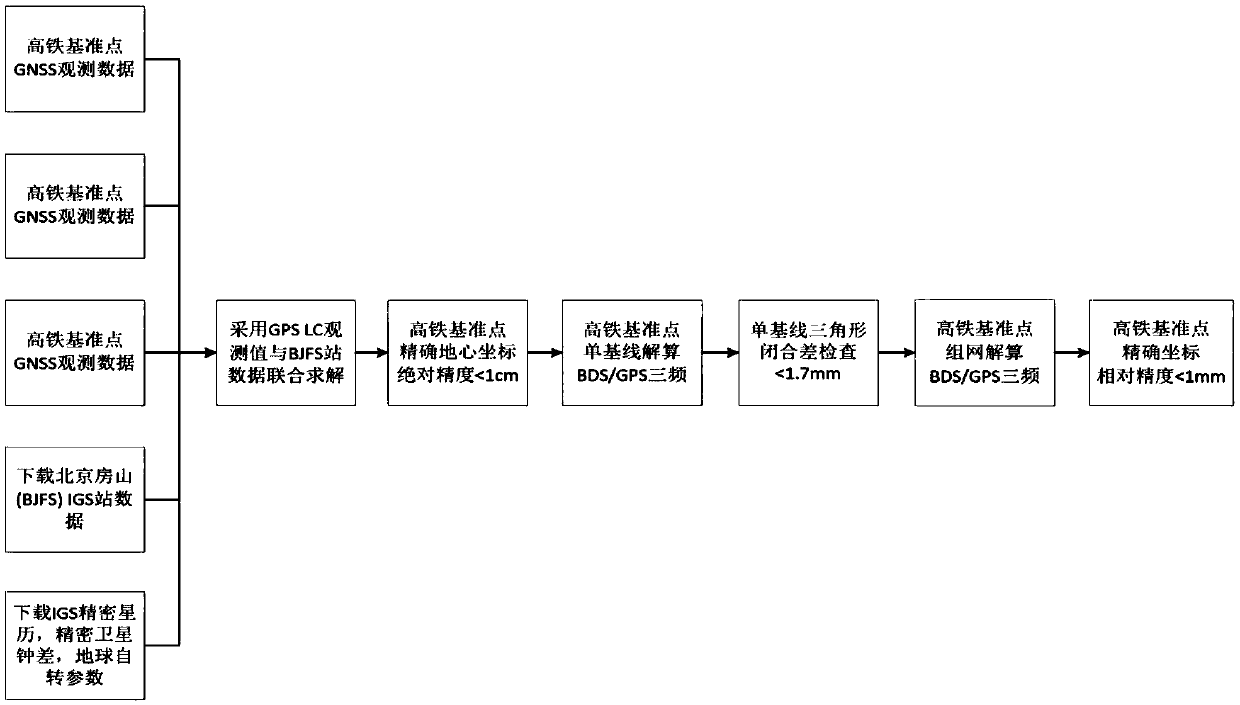

[0031] (1) Get real-time GNSS satellite data from multiple base stations built along the fixed track, and calculate the precise coordinates of the base station;

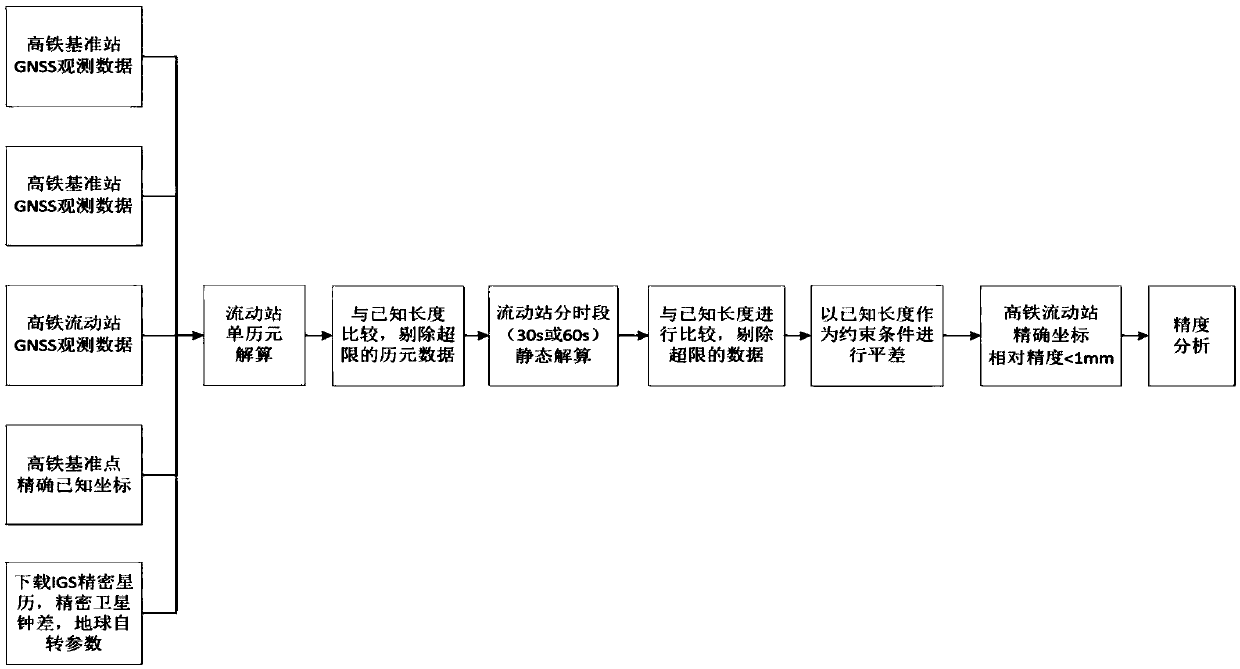

[0032] (2) The track inspection car is placed on the track, observes for a certain period of time, and obtains synchronously observed GNSS satellite data;

[0033] (3) Through the data measured by the track gauge sensor, sleeper identifier, odometer, and inertial navigation system on the track inspection trolley, combined with the satellite data in (1) and (2), calculate the external geometric parameters of each sleeper; use The external geometric parameters and the data on the track inspection trolley calculate the internal geometric parameters of each sleeper, which are used to guide precise track adjustment.

[0034] As a kind of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com