Track detection method and track inspection trolley

A track inspection trolley and track inspection technology, which is applied to railway inspection vehicles, railway car body parts, railway vehicle shape measuring devices, etc., can solve problems such as single working mode, low work efficiency, and inability to meet work needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

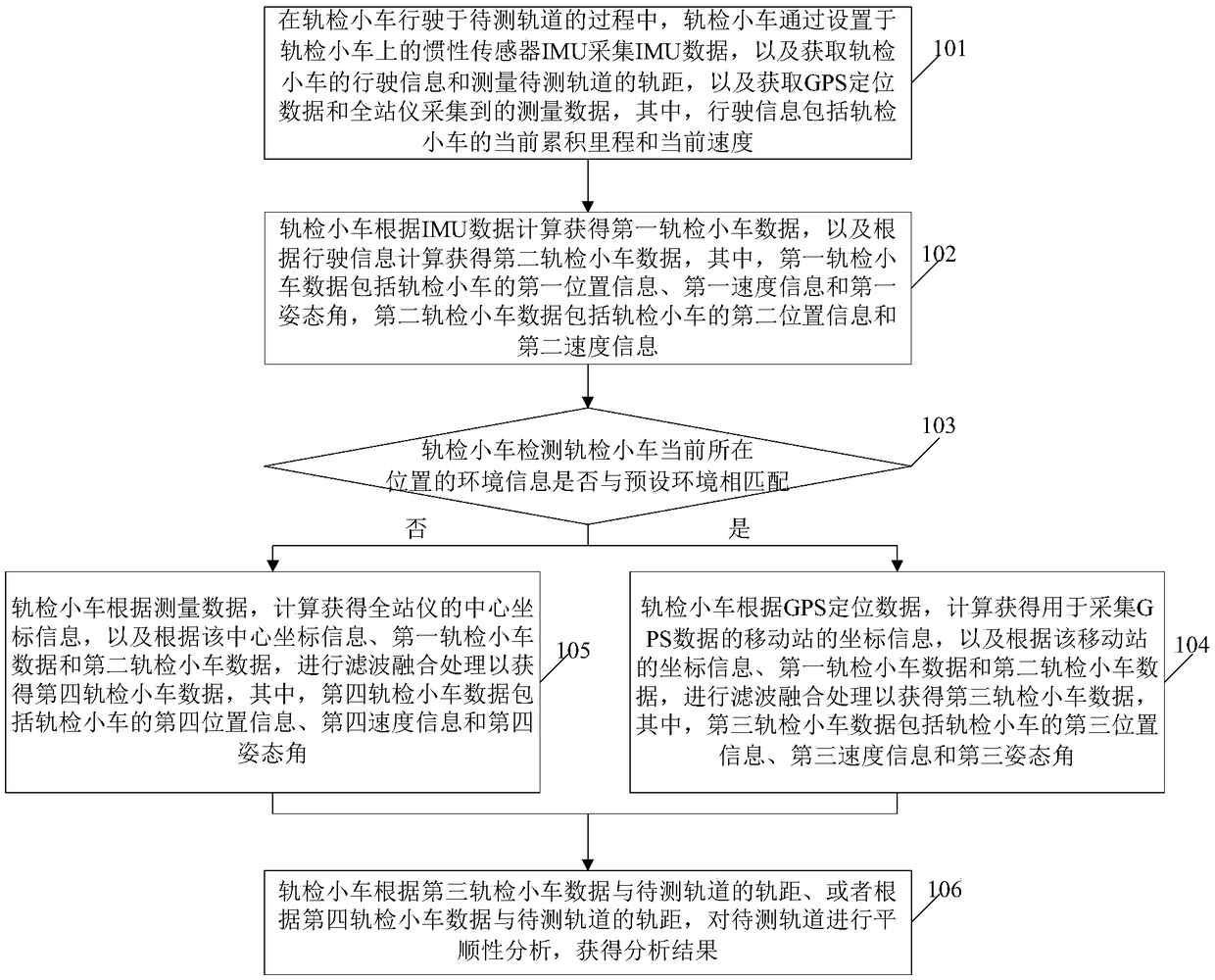

[0069] see figure 1 , figure 1 It is a schematic flowchart of a track detection method disclosed in an embodiment of the present invention. Such as figure 1 As shown, the track detection method may include the following steps.

[0070] 101. When the track inspection trolley is running on the track to be tested, the track inspection trolley collects IMU data through the inertial sensor IMU installed on the track inspection trolley, obtains the driving information of the track inspection trolley and measures the gauge of the track to be tested, And obtain GPS positioning data and measurement data collected by the total station, wherein the driving information includes the current accumulated mileage and current speed of the track inspection trolley.

[0071] It should be noted that before step 101 is executed, the track inspection car can use the 1PPS second pulse of GPS to synchronize the time of the inertial sensor IMU and the total station, so that the time of the GPS, ine...

Embodiment 2

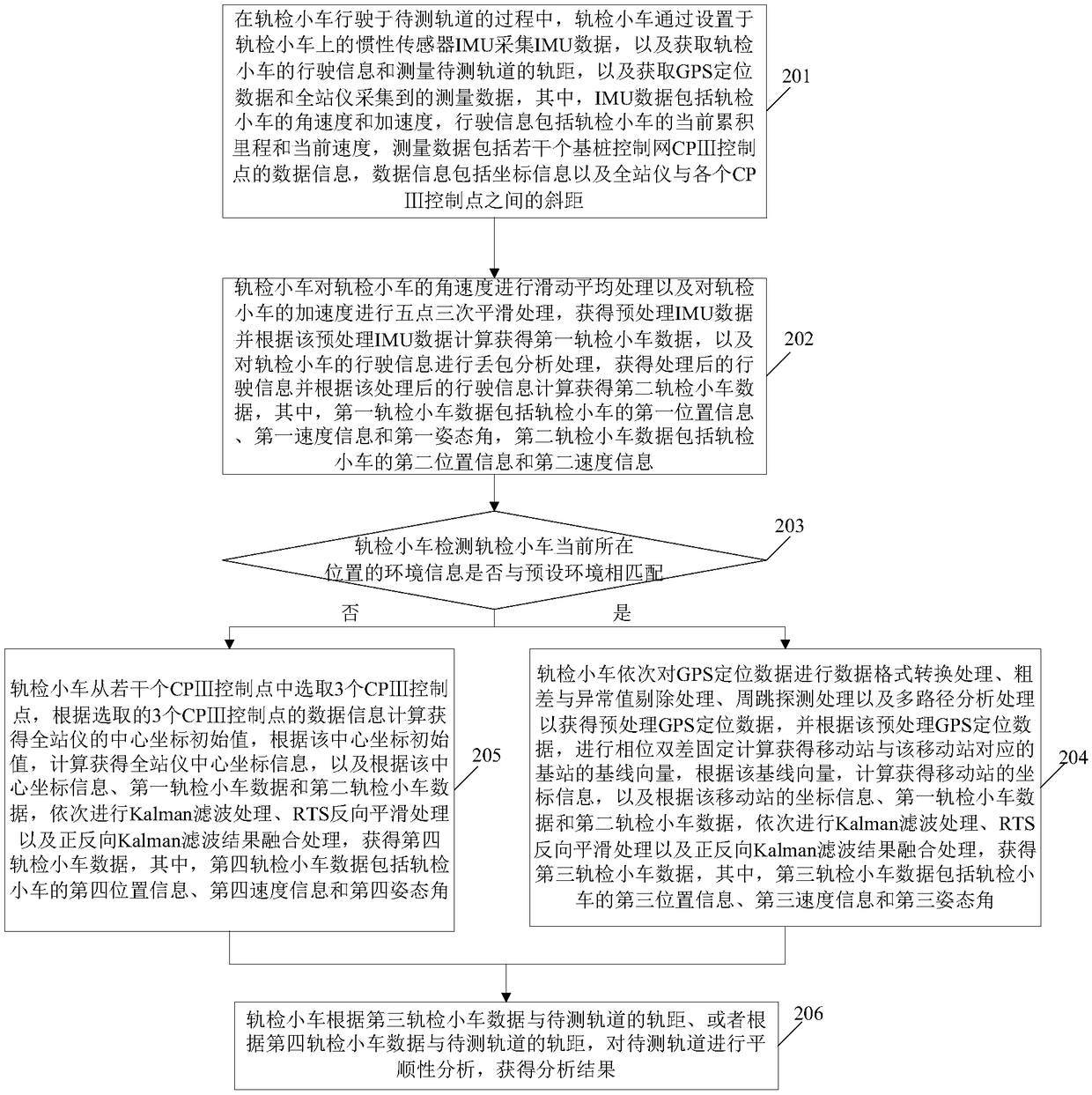

[0092] see figure 2 , figure 2 It is a schematic flowchart of another track detection method disclosed in the embodiment of the present invention. Such as figure 2 As shown, the track detection method may include the following steps.

[0093] 201. When the track inspection trolley is running on the track to be tested, the track inspection trolley collects IMU data through the inertial sensor IMU installed on the track inspection trolley, and obtains the driving information of the track inspection trolley and measures the gauge of the track to be tested. And obtain the GPS positioning data and the measurement data collected by the total station. Among them, the IMU data includes the angular velocity and acceleration of the track inspection car, the driving information includes the current accumulated mileage and current speed of the track inspection car, and the measurement data includes several foundation piles. The data information of CPⅢ control points on the network, ...

Embodiment 3

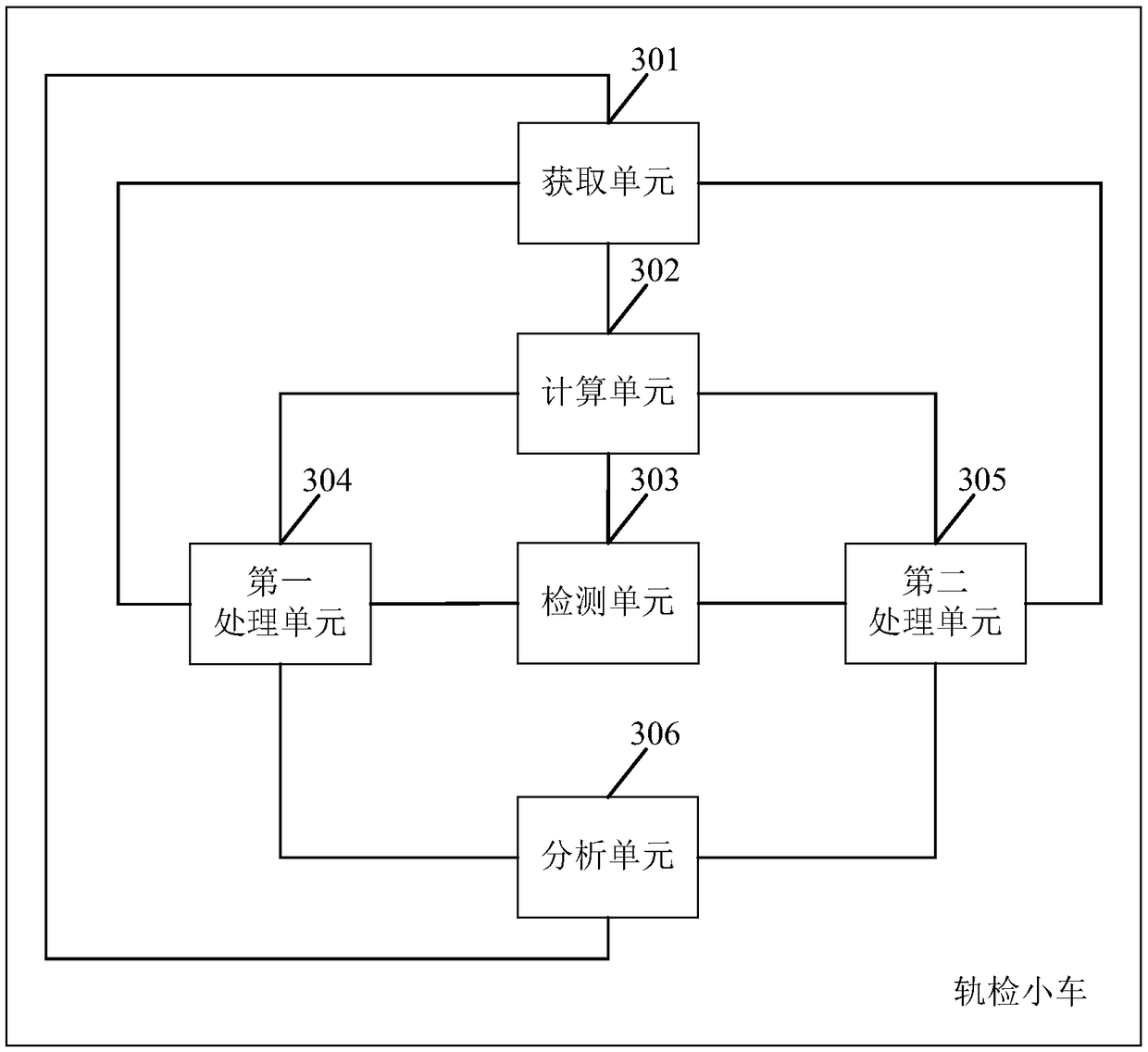

[0141] see image 3 , image 3 It is a structural schematic diagram of a track inspection trolley disclosed in the embodiment of the present invention. Such as image 3 As shown, the track inspection trolley can include:

[0142] The acquisition unit 301 is used to collect IMU data through the inertial sensor IMU provided on the track inspection trolley during the process of the track inspection trolley running on the track to be tested, and to obtain the driving information of the track inspection trolley and measure the gauge of the track to be tested , and obtain GPS positioning data and measurement data collected by the total station, wherein the driving information includes the current accumulated mileage and current speed of the track inspection trolley;

[0143] The calculation unit 302 is used to calculate and obtain the first track inspection trolley data according to the IMU data acquired by the acquisition unit 301, and calculate and obtain the second track inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com