Self-adaptive cutting method for coal mining machine based on virtual trajectory control

A virtual track and shearer technology, applied in cutting machinery, slitting machinery, earthwork drilling and other directions, can solve the problems of lack of effective response and lack of prediction of the geological environment of unmined coal seams, so as to improve the quality of coal, cut Good cutting effect and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

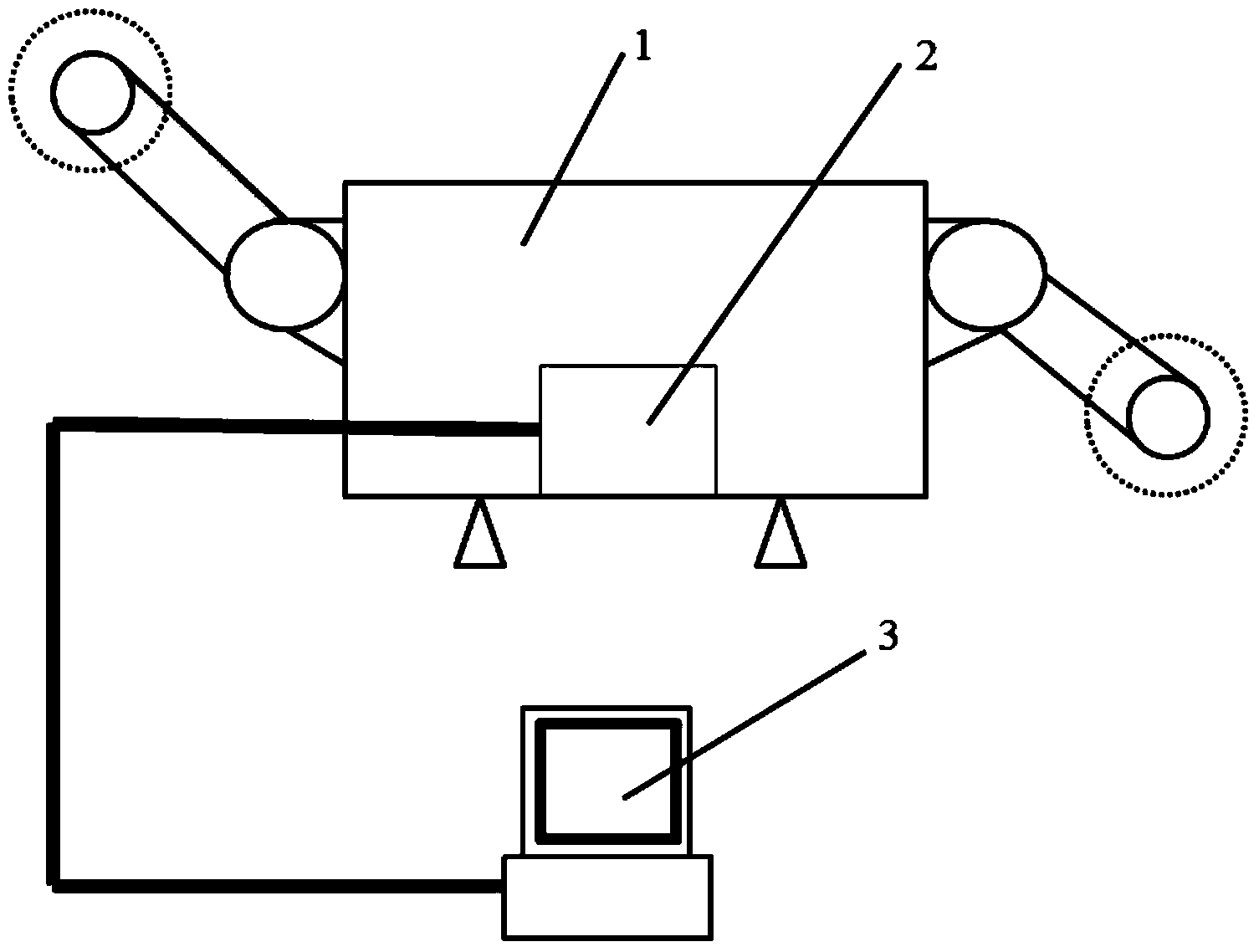

[0041] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

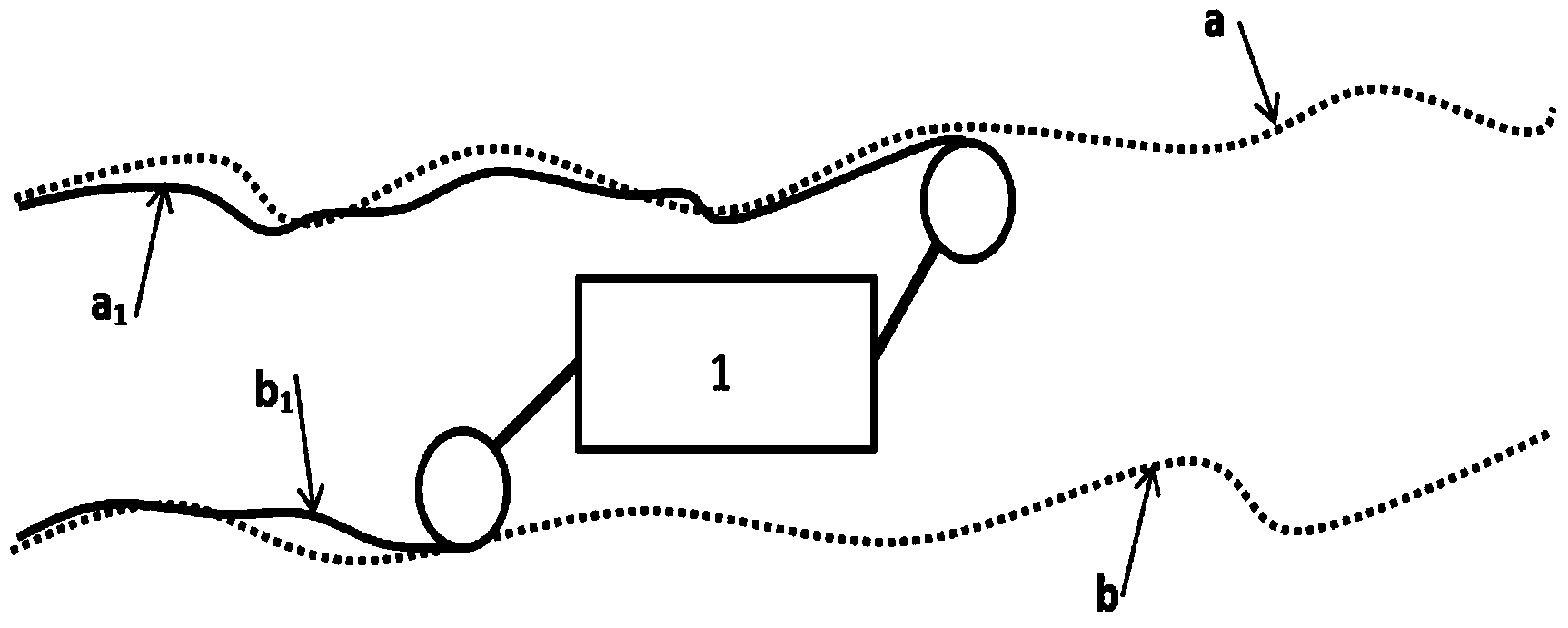

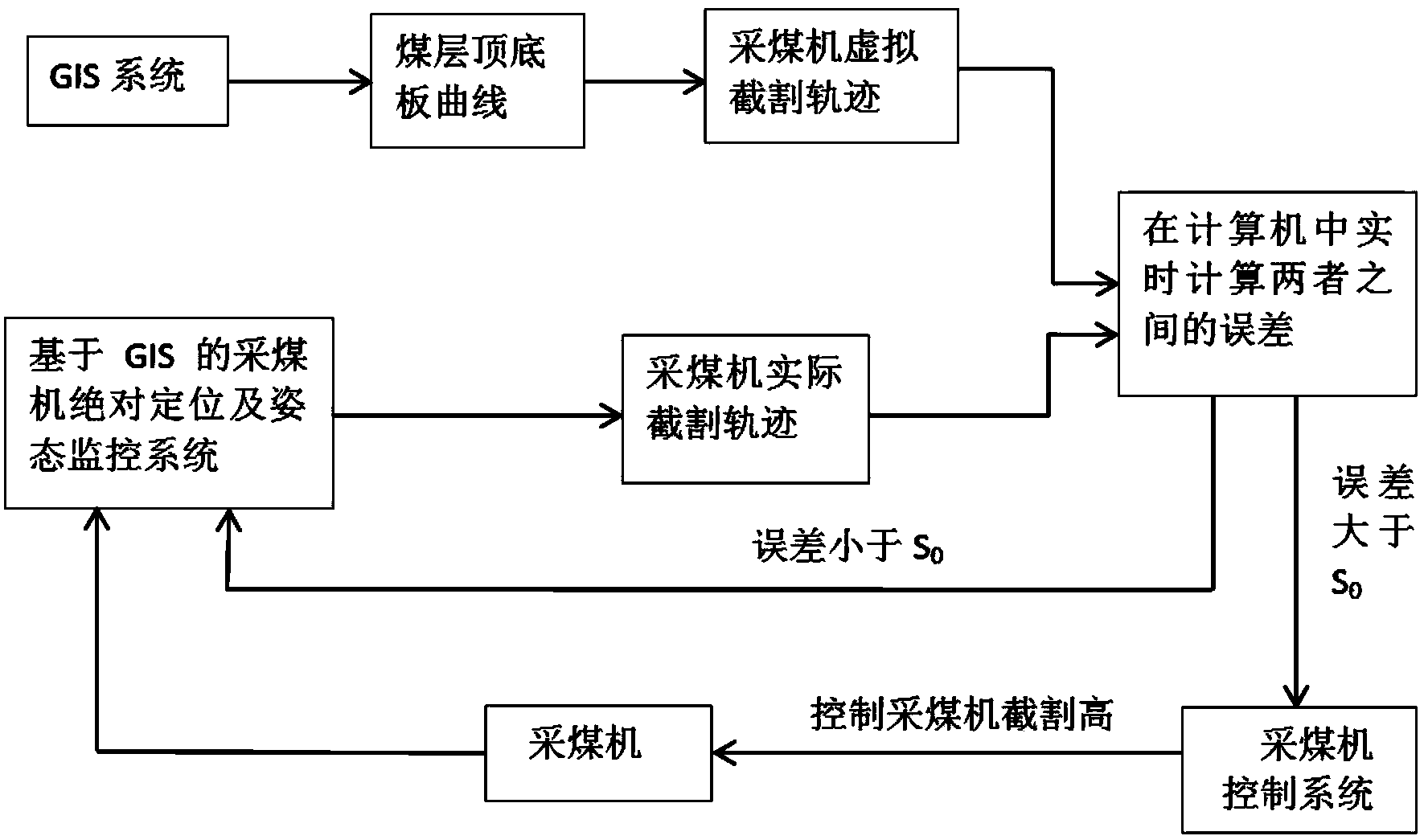

[0042] Such as figure 1 As shown, the present invention is based on the self-adaptive cutting method of the shearer controlled by the virtual trajectory, and the specific steps are as follows:

[0043] (1) According to the roof and floor curves of the mining area, the thickness of the cut coal seam and its changes, and the geological conditions of coal seam inclusions obtained by GIS, the virtual cutting track a of the virtual shearer 1 near the roof and the virtual cutting track b of the virtual shearer 1 near the floor , the series coordinates of the virtual cutting trajectory a in the GIS three-dimensional coordinate system are marked as (X a ,Y a ,Z a ), the series coordinates of the virtual cutting trajectory b are marked as (X b ,Y b ,Z b );

[0044] (2) According to the exploration coal seam thickness h of each coal mine and the mining recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com