Method for compensating precision milling deformation of thin-wall blade

A deformation compensation and milling processing technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large deformation and difficult precision guarantee of thin-walled blades, and achieve improved surface contour and processing accuracy , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Describe the present invention below in conjunction with specific embodiment:

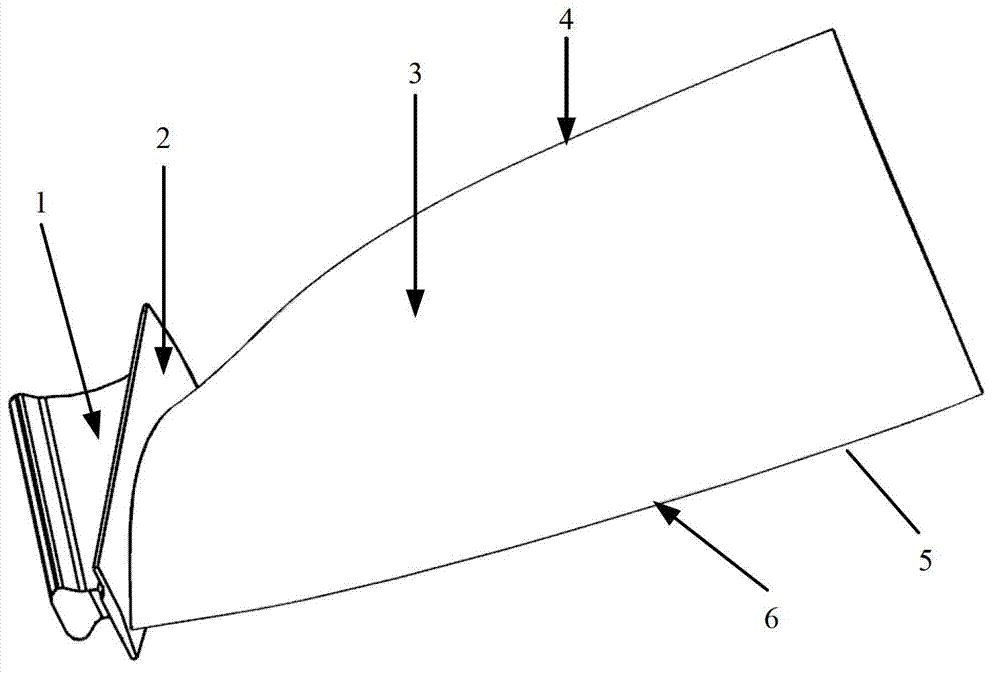

[0034] In this embodiment, the attached figure 2 Take the thin-walled blade of an aeroengine as an example, figure 2 The blade size shown is about: 303mm×115mm×1.8mm, the blade material is aerospace titanium alloy TC4; the cutter diameter is a ball-end cutter with a diameter of 10mm. The blade is processed by JOHNFORD VM850C four-axis CNC machining center. The axial direction of the blade coincides with the X-axis of the machine tool and can rotate 360° around the X-axis. The measuring equipment is a three-coordinate measuring machine GLOBAL STATUS 121510, and the probe radius is 1mm.

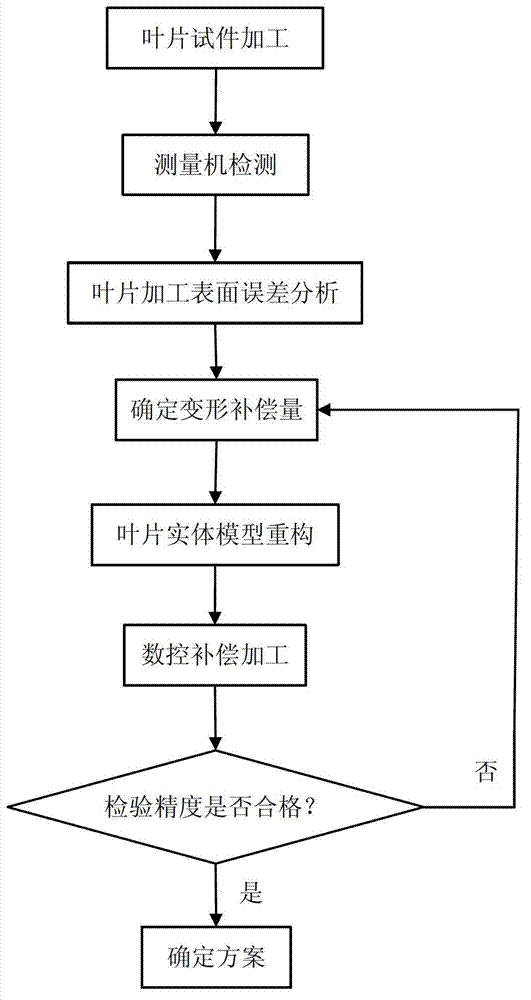

[0035] The specific compensation method steps are as follows:

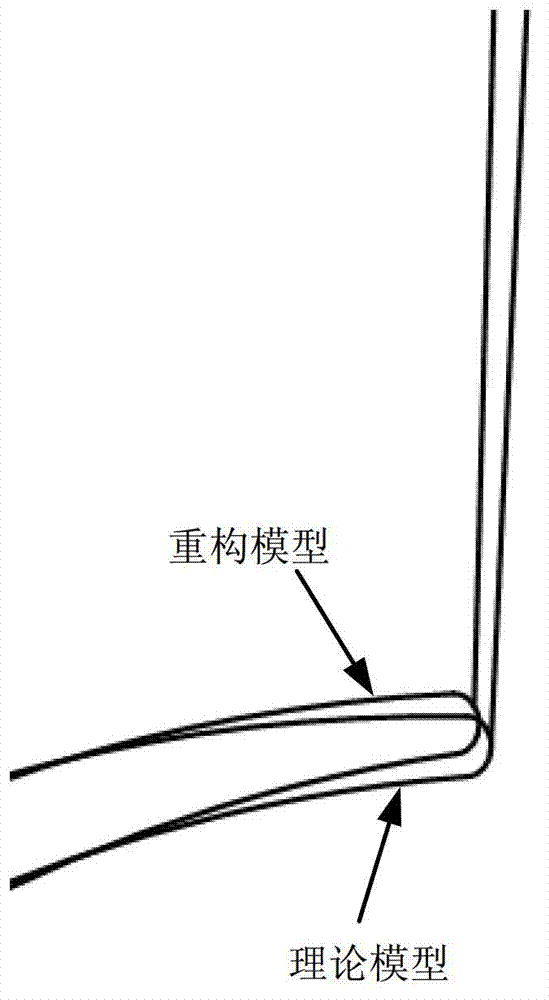

[0036] Step 1: Extract 8 blade sections perpendicular to the parameter v direction in the 3D model of the blade, and extract the section lines of each blade section. The method of obtaining compensation for each section line is the same; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com