Precise milling processing method with variable inter-row allowance for thin walled blade of difficult-to-process material

A technology that is difficult to process and blades is applied in the field of precision and ultra-precision milling. It can solve the problems of difficult to guarantee accuracy and large processing deformation, and achieve the effect of realizing precise control, solving large torsional deformation, and improving surface contour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Describe the present invention below in conjunction with specific embodiment:

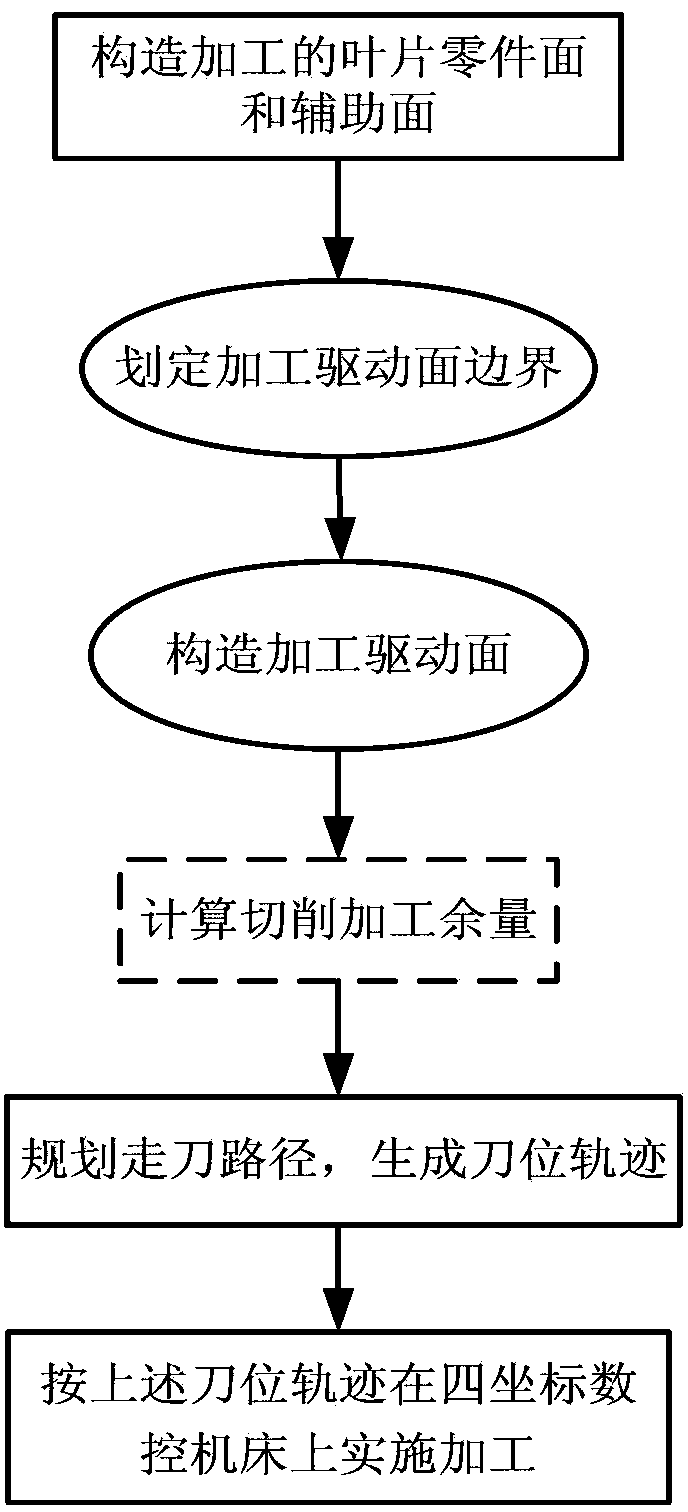

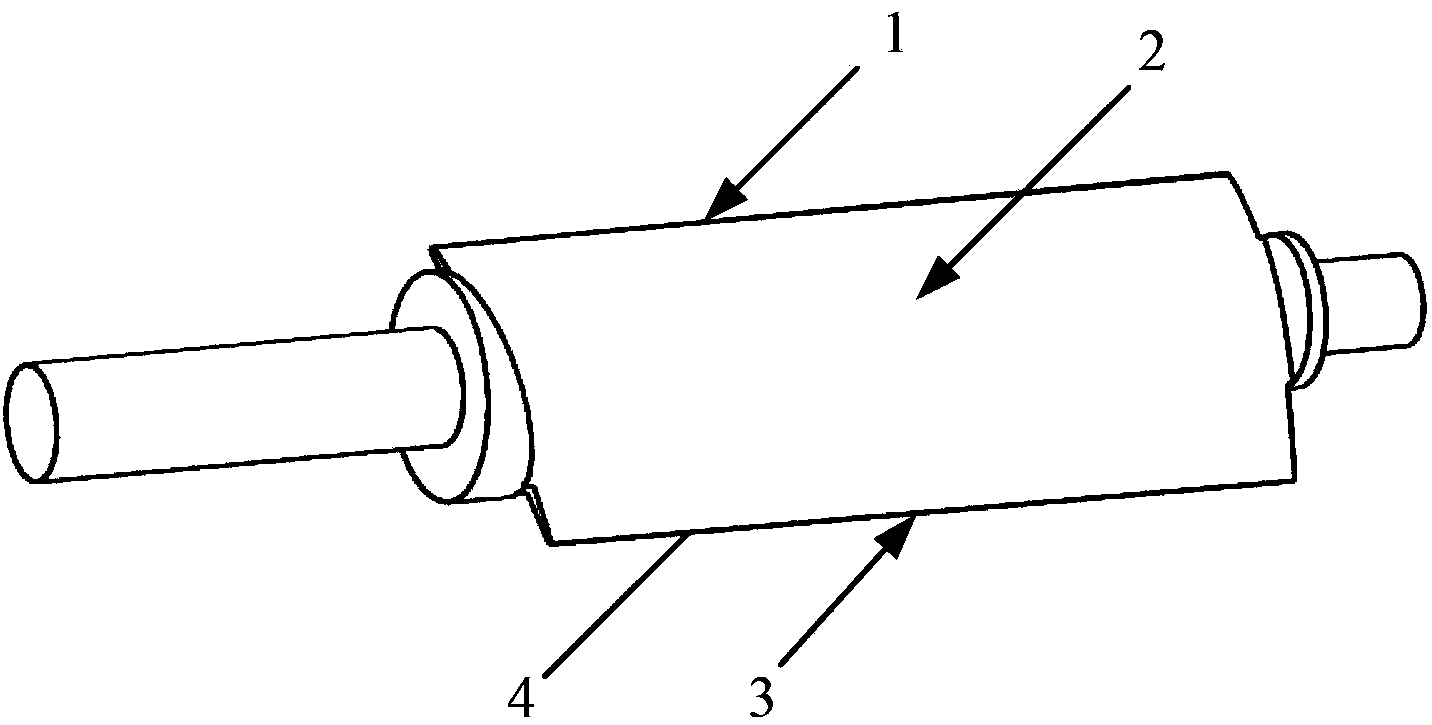

[0030] This embodiment takes figure 2 Take the thin-walled blade of an aeroengine as an example, figure 2 The size of the blade shown is about: 72mm×26mm×1.5mm, and the diameter of the cutter is 6mm. The concrete implementation process of the present invention is as figure 1 shown.

[0031] The blade is processed by a four-axis CNC machining center. The axial direction of the blade coincides with the X-axis of the machine tool and can rotate 360° around the X-axis. The specific steps of implementation are as follows:

[0032] Step 1: According to the blade design data given by the design department, construct the 3D model of the blade in the 3D modeling software; Auxiliary surface.

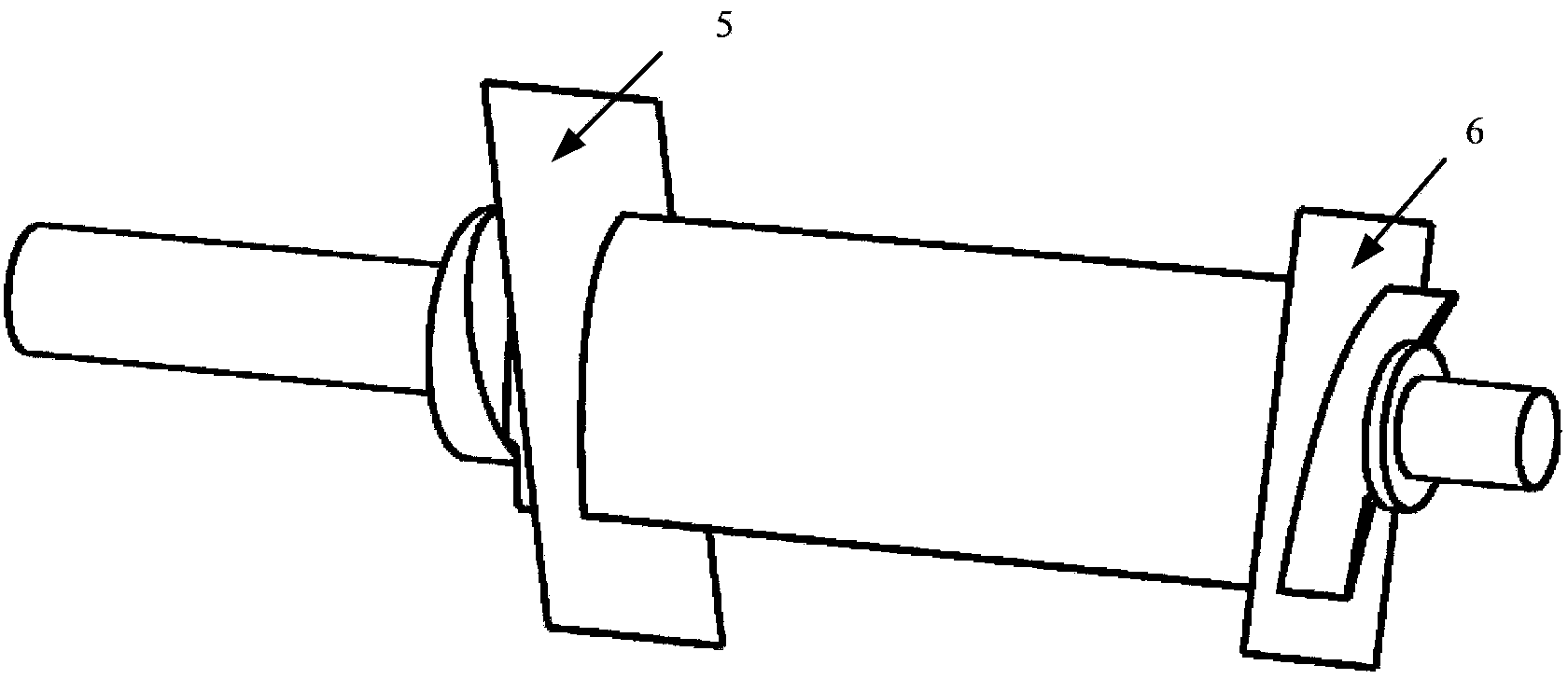

[0033] Step 2: In the 3D model of the blade, both ends of the blade are offset towards the blade body. The offset distance ensures that the tool does not interfere with the blade end surface during machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com