Precision milling method based on elliptic parameter equation with variable margin control of blade inlet and outlet

A technology of inlet and exhaust edges and parametric equations, applied in milling machine equipment, manufacturing tools, details of milling machine equipment, etc., can solve problems such as poor accuracy, and achieve the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

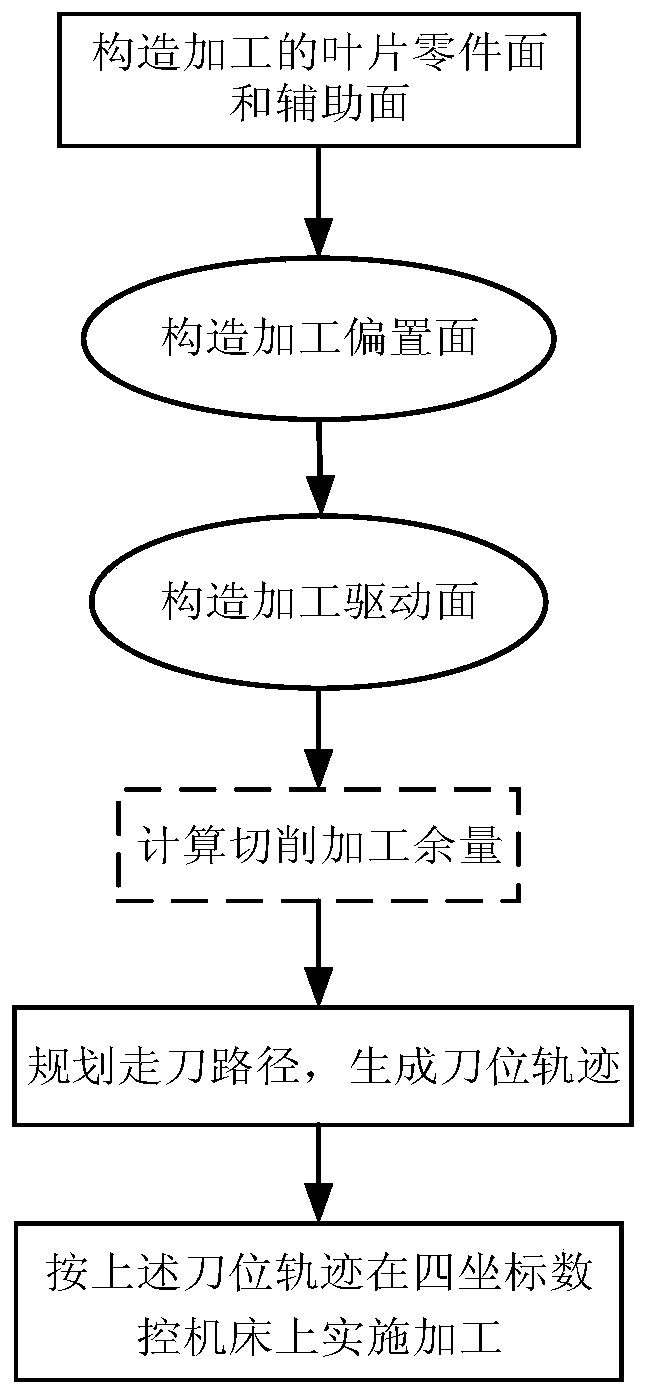

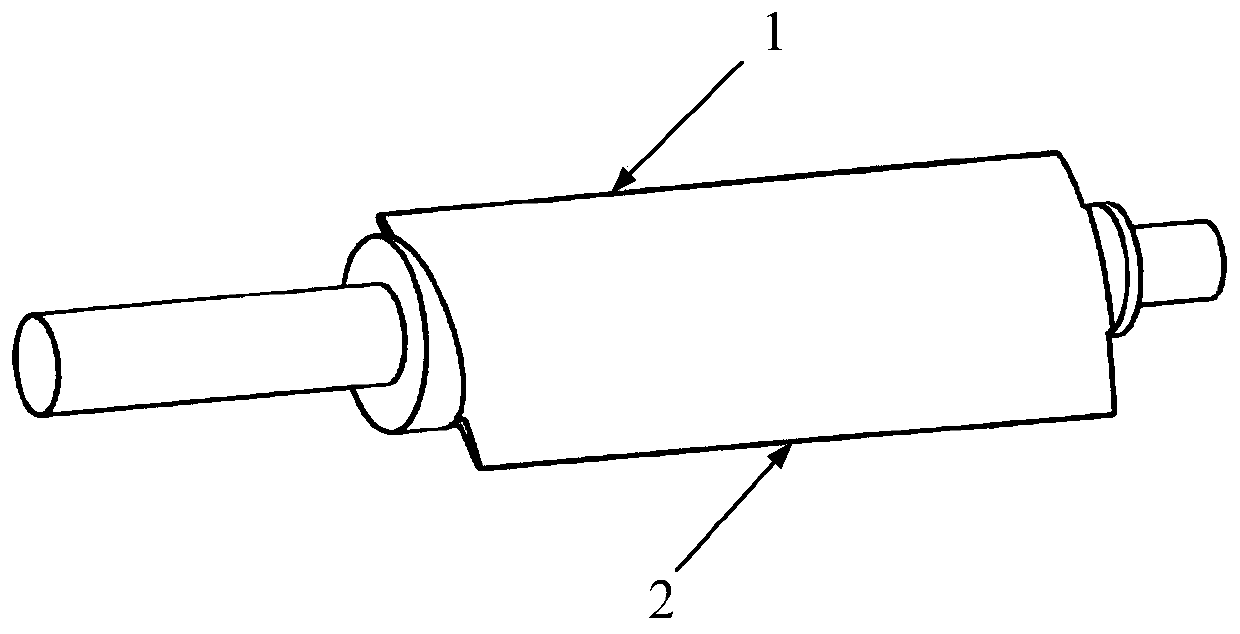

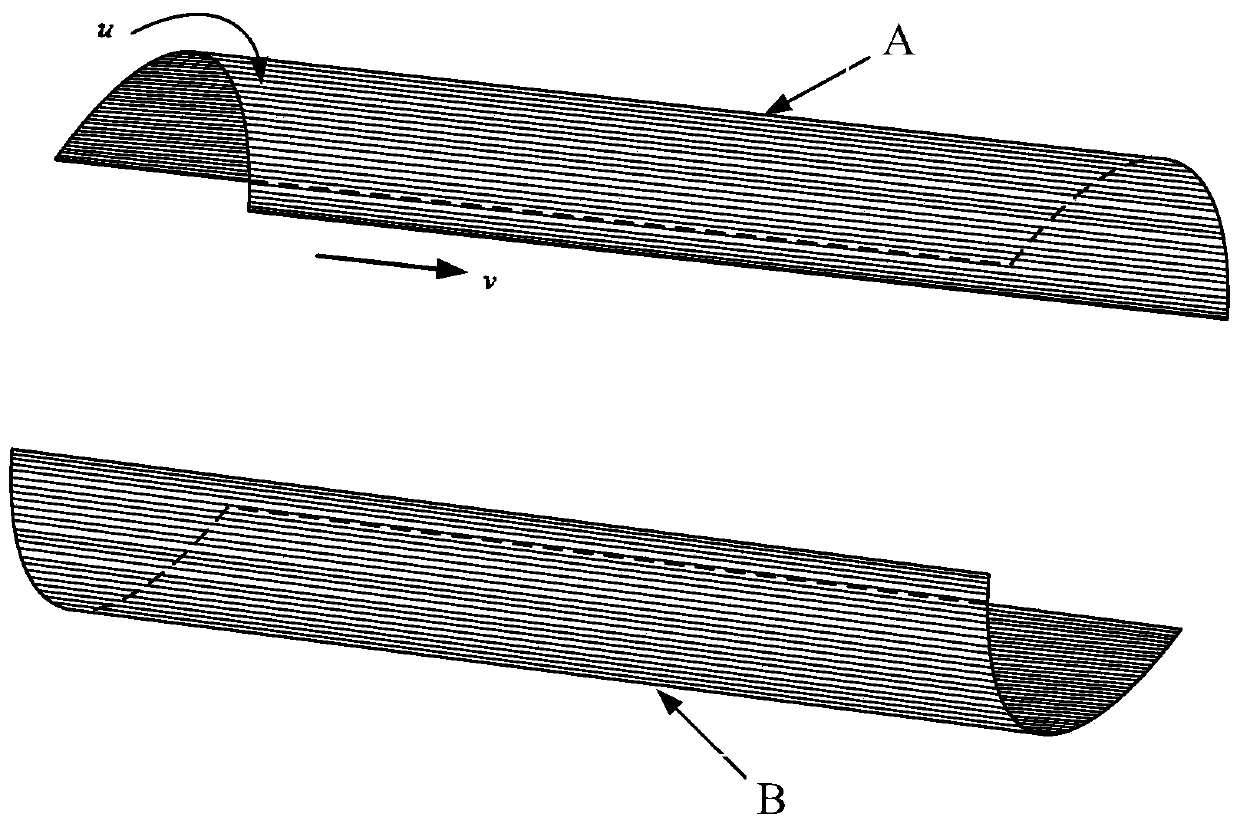

[0041] refer to Figure 1-9 . Take an aero-engine thin-wall guide vane intake and exhaust side as an example, the blade size is: 80mm×27mm×1.5mm, the radius of the intake and exhaust side is 0.2-0.5mm, and the diameter of the tool is 6mm. Firstly, three-dimensional modeling software is used to construct the driving surface of the intake and exhaust edge processing, and the section line lofting method is used to uniformly parameterize it, and then the tool position is planned to calculate the tool trajectory, and the initial processing path, the middle processing path and the end processing path are selected. There are nine points in total including the starting point, the middle point and the end point, and the machining allowance is set, and then the machining allowance of each tool position point under any machining path is determined by using the elliptic parameter equation and the Newton interpolation algorithm, and finally according to the planned machining allowance The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com